Sealant and Adhesive Supply Systems

General Industry Supply Systems

General Industry Supply Systems deliver one-component sealants, adhesives and grease from 200 or 60 liter drums to metering and dispensing systems. Reliable performance at an affordable price.

Features

- Assembled in Suzhou for fast delivery

- Optional DataTrak™ accessory allows machine monitoring

- Optional PLC Interface accessory allows a PLC to directly read the low level and cycle count sensors, and stop and start the pump

- Optional Light Tower accessory is available to indicate system diagnostics

SmartWare Technology

The SmartWare Shot Dispense Kit contains everything you need to convert your existing Graco pump into a dosing system. It’s an accurate, economical way to dose material – saving you time, material and labor costs.

Compatible with DuraFlo or CheckMate pumps with NXT Air Motor technology and most Graco Supply Systems

Features

- Allows you to dose a preset amount of single-component material with your Graco pump

- A great alternative to manual methods such as mechanical counters, scales or custom systems

- An economical alternative to fully automated systems

- Shot size ranges from 6 cc’s to 1000 gal (3,785 L)

- Accuracy ranges from 0.25 to 4%, depending on material and shot size

| SmartWare Shot Dispense Kit | |

|---|---|

| Power Supply Requirements | 100 – 240 Vac, 50/60 Hz, single phase, 1.2 amps max |

| Pressure Transducer Manifold | |

| Maximum Working Fluid Pressure | 52.5 MPa/5.25 bar |

| Ambient Operating Temperature Range | 0 to 49° C |

| Operating Humidity Range | 0 – 90% non-condensing |

Supply Systems

Graco Supply Systems reliably deliver one-component sealants, adhesives and other medium to high-viscosity materials from pails or drums to metering and dispensing systems.

For large drums up to 200 liter (55 gal)

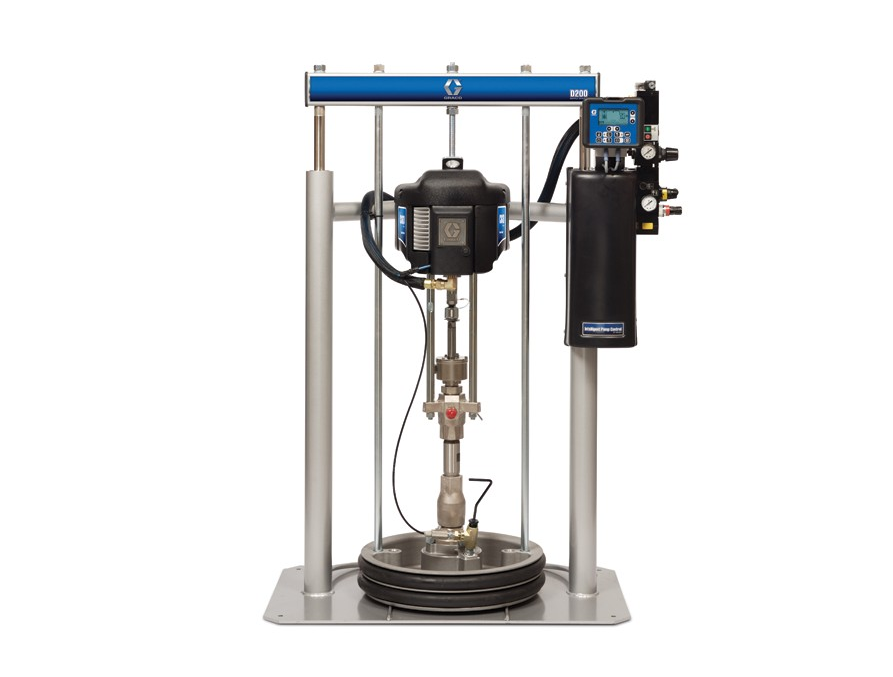

- Graco D200 – For high-volume in-plant applications

- Graco D200s – For heavy-duty, high-volume applications of high-viscosity materials. Provides more down-force for difficult-to-move materials

For pails up to 60 liter (16-gal)

For 20, 30 and 60 liter (5, 7, and 16-gal) pail sizes. Provides the same proven technologies as the larger systems, but with small NXT Air Motors.

- Graco L20c – A lightweight, elevator ram on a cart

- Graco S20 – For low-volume applications of medium to high-viscosity materials

- Graco S20c – Same as the S20, but includes a cart

- Graco D60 – Provides higher down-force and 60-liter pail capacity

Features

- Industry-first controls give you immediate and important information at the touch of a button

- Quick placement of drum or pail

- Platen wipers can be replaced in seconds

- Pump’s quick-disconnect coupler, turbuckle mount and pump cartridge packings let you service the pump without removing it from the ram

- High-quality, durable parts reduce maintenance time, maximize uptime

Specification

| Supply Systems | |

|---|---|

| Max air input pressure (supply system) / Air inlet size | |

| L20c – 2 in elevator, 5 gal (20 l) | 0.7 MPa, 7 bar / 1/2 npsm(f) |

| S20 – 3 in single post, 5 gal (20 l) | 0.9 MPa, 9 bar / 1/2 npt(f) |

| D60 – 3 in dual post, 16 gal (60 l), 5 gal. (20 l), 30 gal | 1.0 MPa, 10 bar / 3/4 npt(f) |

| D200 – 3 in dual post, 55 gal (200 l), 30 gal (115 l),16 gal (60 l), 8 gal (30 l), 5 gal (20 l) | 1.0 MPa, 10 bar / 3/4 npt(f) |

| D200s – 6.5 in dual post, 55 gal (200 l), 30 gal (115 l) | 0.9 MPa, 9 bar / 3/4 npt(f) |

| Max fluid, air working pressure. and weight (displacement pump) | |

| For Check-Mate pump packages, see manual 312376. For Dura-Flo pump packages, see manuals 311826, 311828, 311833. | |

| Pump Wetted parts | |

| For Check-Mate displacement pumps, see manual 312375. For Dura-Flo displacement pumps, see manuals 311717, 311825, 311827. | |

| Platen Codes: Part number; Wetted parts | |

| B : 257727, 5 gal (20 l), J : 257732, 8 gal (30 l), S : 257737, 16 gal (60 l) | Electroless nickel, polyurethane, nitrile, carbon steel, polyethylene, zinc plated carbon steel, buna, 316 sst, 17-4PH sst |

| C : 257728, 5 gal (20 l), K: 257733, 8 gal (30 l), T: 257740, 16 gal (60 l) | Electroless nickel, polyurethane, carbon steel, polyethylene, nitrile, zinc plated carbon steel, buna, 316 sst 17-4PH sst |

| F : 257729, 5 gal (20 l), L : 257734, 8 gal (30 l), U : 257738, 16 gal (60 l) | Stainless steel, polyurethane, PTFE coated nitrile, polyethylene, nitrile, PTFE, 303 sst, 304 sst, 316 sst, 17-4PH sst |

| G : 257730, 5 gal (20 l), M : 257735, 8 gal (30 l), W : 257739, 16 gal (60 l) | Electroless nickel, aramind reinforced elastomer, rubber- based PSA, nitrile, polyethylene, zinc plated carbon steel, buna, 1018 carbon steel, 304 sst, 316 sst, 17-4PH |

| H : 257731, 5 gal (20 l), R : 257736, 8 gal (30 l), Y : 257741, 16 gal (60 l) | Electroless nickel, aramind reinforced elastomer, rubber- based PSA, polyurethane, polyethylene, nitrile, zinc plated carbon steel, buna, 1018 carbon steel, 304 sst, 316 sst, 17-4PH sst |

| 7 : 255661, 30 gal (115 l) | zinc plated carbon steel, EPDM, sst, fluoroelastomer |

| 8 : 255662, 55 gal (200 l) | PTFE, EPDM, PTFE coated aluminum, zinc plated carbon steel, 316 sst |

| 9 : 255663, 55 gal (200 l) | EPDM, aluminum, zinc plated carbon steel, 316 sst |

| A : 255664, 55 gal (200 l) | PTFE, neoprene, aluminum, zinc plated carbon steel, |

| Ambient operating temperature range (supply system) | |

| 0- 49°C | |

| Sound data | |

| See separate air motor manual. | |

| External power supply requirements (DatraTrak) | |

| AC power units | 100-240 Vac, 50/60 Hz, single phase, 1.2 amps max |

| DC power units | 24 Vdc, 1.2 amps max draw |

Warm Melt Supply Systems

Designed specifically for sealants or adhesives that need to be warmed up to 100°C (212°F), Graco Warm Melt Supply Systems deliver superior temperature control. Ideal for temperature conditioning applications. An excellent alternative to water-jacketed solutions.

Features

- Bridges the gap between hot melt and ambient supply systems

- Modular approach provides easy snap-on installation and eliminates complex point-to-point wiring

- Intuitive, easy-to-use interface

- Configurable to fit your unique application and material

Specification

| Warm Melt Supply Systems | |

|---|---|

| Maximum Air Input Pressure | |

| D60 | 10 bar, 1 MPa |

| D200 | 10 bar, 1 MPa |

| D200s | 9 bar, 0.9 MPa |

| Platen Wetted Parts (By Platen Code and Part Number) | |

| F: 257729, 5 gal (20 l) | Stainless steel, polyurethane, PTFE coated nitrile, polyethylene, nitrile, PTFE, 303 sst, 304 sst, 316 sst, 17-4PH sst |

| L: 257734, 8 gal (30 l) | |

| U: 257738, 16 gal (60 l) | |

| H: 257731, 5 gal (20 l) | Electroless nickel, aramind reinforced elastomer, rubber-based PSA, polyurethane, polyethylene, nitrile, zinc-plated carbon steel, buna, 1018 carbon steel, 304 sst, 316 sst, 17-4PH sst |

| R: 257736, 8 gal (30 l) | |

| Y: 257741, 16 gal (60 l) | |

| 8: 255662, 55 gal (200 l) | PTFE, EPDM, PTFE coated aluminum, zinc-plated carbon steel, 316 sst |

| 9: 255663, 55 gal (200 L) | EPDM, aluminum, zinc-plated carbon steel, 316 sst |

| Displacement Pump | See Check-Mate Displacement Pump and Pump Packages for wetted parts, weight, flow rate, and maximum fluid and air working pressure |

| Maximum Operating Temperature (Supply System) | 70°C |

| Sound Data | See NXT Air Motor |

| External Power Supply Requirements | |

| AC Power Units | 220-250 Vac, 50/60 Hz, single phase, 57 amps full load current |