CKSF

“Wish the Body Was a Little Thinner…” Is Finally Responded

- Very thin body

- Simple structure

- Large body type and hollow body type available

- Pushers (option)

- How to design external fingers to maximize dust-resistance ability

Internal cylinders are located on the side toward workpiece, and which makes the motion of the cylinders parallel to jaw. These changes reduces thickness of the gripper by a half for use in confined spaces.

Direct drive mechanism to minimize hooking problem instead of worm drive mechanism. Motion failure caused by lack of grease can be also minimized.

Workpiece pushers can be additionally mounted (option)

3-point pusher for steady workpiece loading

Please reduce the room between external finger and the gripper surface (as shown on the right)

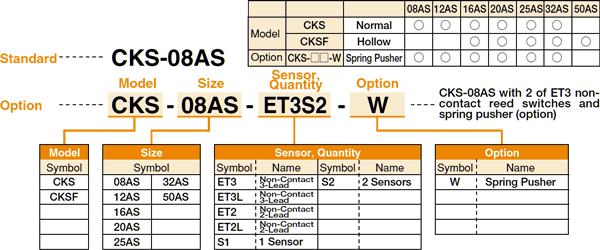

Method of model

Specification

| Model | CKSF-16AS | CKSF-20AS | CKSF-25AS | CKSF-32AS | CKSF-50AS | |

|---|---|---|---|---|---|---|

| WorkingPressure | Pneumatic:0.2 to 0.7MPa | |||||

| Lubrication | Not Required or Turbine Oil Class 1(ISOVG32) | |||||

| Ambient Temperature (℃) | 5 to 60 | |||||

| Total Jaw Stroke(mm) | 16 | 20 | 28 | 32 | 50 | |

| CylinderDiameter | (mm)Open | dia.12×3 | dia.16×3 | dia.20×3 | dia.25×3 | dia.40×3 |

| (mm)Closed | dia.16×3 | dia.20×3 | dia.25×3 | dia.32×3 | dia.50×3 | |

| Internal Volume[Reciprocation](cm3/time) | 7.6 | 15.5 | 33.8 | 62.2 | 242 | |

| Repeatability(mm) | ±0.01 | |||||

| Weight (kg) | 0.44 | 0.66 | 1.17 | 1.82 | 5.76 | |