Journal Jack

SPD SERIES

Compact & high power hydraulic press is used for high pressure hydraulic pump. The press enables saving of idling stop and speed regulation with inverter as standard equipment.

Standard equipment

Color touch panel

Inverter

Electric control panel

Slide position detection device

Pressurization force detection

Option

Light curtain safety device ( front )

Safety cover

Water cooled oil cooler

HPA SERIES

Highly precision & high level of safety portal press.

Models ranging from 1000kN to 5000kN

Highly speed type adopted double acting cylinder

Productivity; available for forming speed according to capacity by adopting variable displacement pump.

Energy conservation; Electricity consumption is reduced at pump delivery control during idling.

Saving resources; Saving 20% of oil volume for tank

Press precision ; JIS 1 grade

Standard equipment

Color touch panel

Slide position detection device

Pressurization force detection

Two hands push button

Safety block

Water cooled oil cooler

Option

Light curtain safety device ( Front , back )

Safety cover

Die lifter , support lifter

Upper knockout

Bottom knockout

Moving table

Mechanical stopper at bottom dead center

HPC-N SERIES (Column guide type)

Highly versatile, high level of safety C type press.

Model ranging from 300kN – 1500kN

Available for speed control based on forming by inverter

High speed type adopted double acting cylinder

Energy conservation; Electricity consumption is reduced at idling stop by inverter control.

Saving resources; Contribute oil change cycle to protect deterioration Of working oil & lower generation of heat.

Open space is installed in backside considering work efficiency.

Standard equipment

Color touch panel

Slide position detection device

Pressurization force detection

Two hands push button

Safety block

Option

Light curtain safety device ( Front )

Safety cover

Die lifter , support lifter

Water cooled oil cooler

HPC-H SERIES (Giv guide type)

Highly versatile, high level, of safety C type press

Models ranging from 300kN – 1500kN

Available for speed control based on forming by inverter.

High speed type adopted double acting cylinder.

Energy consumption; Electricity consumption is reduced at idling stop by inverter control.

Saving resources; contribute oil change cycle to protect deterioration of working oil & lower generation of heat.

Open space is installed in backside considering work efficiency.

Standard equipment

Color touch panel

Slide position detection device

Pressurization force detection

Two hands push button

Safety block

Option

Light curtain safety device ( front )

Safety cover

Die lifter , support lifter

Water cooled oil cooler

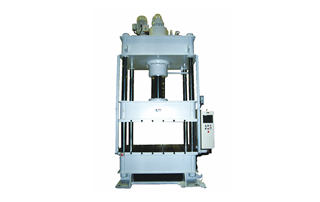

HPD SERIES

Highly versatile, high level of safety four columns type press

Models ranging from 300kN – 5000kN

Available for speed control based on forming by inverter.

High speed type adopted double acting cylinder

Energy conservation; Electricity consumption is reduced at idling stop by inverter.

Saving resources; Contribute oil change cycle to protect deterioration of working oil & lower generation of heat.

Press precision : JIS 2 grade

Standard equipment

Color touch panel

Slide position detection device

Pressurization force detection

Two hands push button

Safety block

Option

Light curtain safety device( front , back )

Safety cover

Die lifter , support lifter

Water cooled oil cooler

Hydraulic die cushion

Mechanical stopper of bottom dead center

HPE SERIES

Highly precision & safety , excellent filter press

Models ranging from 1000kN – 5000kN

High speed type adopted double acting cylinder

Productivity; available for forming speed based on pressurized force by adopting variable delivery pump.

Energy conservation; Electricity consumption is reduced by pump delivery control during idling.

Saving resources ; Tank capacity reduced 20 % due to saving generation of heat.

Press precision ; JIS 1 grade

Standard equipment

Hydraulic die cushion

Color touch panel

Slide position detection device

Pressurization force detection

Two hands push button

Safety block

Water cooled oil cooler

Option

Light curtain safety device( front , back )

Safety cover

Die lifter, support lifter

Upper knockout , bottom knockout

Multistage cushion pressure control

Moving table

Mechanical stopper of bottom dead center

HPF SERIES

Only can manufacturing press applicable to bending of steel plate, forming , straightening. The press has larger open space, inserting materials from backward and forward.

Models ranging from capacity ; 2000kN – 10000kN

Wider table area type.

Available for inching operation at lower speed with inverter speed control.

Energy conservation; Electricity consumption is reduced by idling stop with inverter.

Saving resources; Contribute oil change cycle to protect deterioration of working oil & lower generation of heat.

Standard equipment

Color touch panel

Slide position detection

Pressurization force device

Two hands push button

Safety block

Option

Light curtain safety device( Front , back )

Safety cover

Attachment for upper die

Water cooled oil cool

Ram head rotation type

Lifting roller in front of and behind press