Tsubaki Zip Chain Lifter

- High speed: Operation three to ten times faster than that of conventional hydraulic lifting equipment

- High frequency: Continuous lifting and lowering at rate of one lift cycle per minute.

- High durability: Cleared more than one million lift cycles in endurance tests

- High efficiency: Over 20% more energy-efficient than hydraulic lifting equipment

What is a zip chain?

Zip chain leverages Tsubakimoto Chain’s global market-leading chain technology to allow pushing and pulling applications.

Ordinary chain is used for pulling applications; it is not capable of transferring power when pushed.

In contrast, zip chain consists of two chains employing hook-shaped plates that interlock to form a single, strong column that can be pushed and pulled.

When lifting, the Zip Chain Lifter interlocks two zip chains to form a strong, rigid, column-shaped body that pushes up the platform. When descending, the chains are unlinked and stored in a compact housing.

Features

1. High efficiency

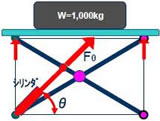

– Drive force is transmitted directly because the zip chain mechanism pushes up the platform directly. No excessive load is placed on the hinges or roller bearings of the pantograph (scissor arms).

– The Tsubaki Zip Chain Lifter has cleared more than one million lift cycles in endurance tests conducted by Tsubakimoto Chain. Its outstanding durability ensures long lifetime.

Durability: Over 1,500,000 lift cycles

The weight and thrust of the lift unit are supported by the zip chain and only a small offset load is placed on the hinges or roller bearings of the scissor arms.

Durability: 50,000 to 300,000 lift cycles

A force of 1/sinθ times the lifted weight is placed on the scissor arms and hinges.

5.8 times more force when θ = 10°

2. High-speed, high-frequency operation

– Enables high-speed lifting at speeds of 50 m/min. Supports high-frequency operation of continuous raising and lowering at rate of one lift cycle per minute.

Comparison with hydraulic lifter

| Feature | Zip Chain Lifter | Hydraulic lifter |

|---|---|---|

| Speed | 0.0 to 50.0 m/min | 0.0 to 12.0 m/min |

| High-frequency operation | Continuous operation possible | Difficult due to increase in oil temperature |

| Life (lift cycles) | 1,000,000 to 1,500,000 times | 50,000 to 300,000 times |

3. Easy control of positioning and speed

– The Zip Chain Lifter lifting mechanism operates by pushing the platform directly up at a constant speed proportional to the speed of the motor. Setting multiple stops and multi-level positioning are also easily achieved.

4. Energy-efficient and environmentally friendly

Compared to conventional lifting devices that push pantograph arms diagonally upward, the Zip Chain Lifter is 20.3 percent more energy efficient in terms of transmission efficiency. Moreover, this efficiency remains unchanged when operating at speeds of between 1 to 50 m/min or even if the cycle time is reduced. (Hydraulic lifters may suffer reduced efficiency or become inoperable due to rising oil temperature.)

It also features a regeneration unit that returns energy produced when the platform is lowered to the primary power system, allowing the lifter to recover 30 percent of electricity consumption.

Successfully introduced products

– Automobile factory assembly line (180+ units)

– LCD display and solar cell production processes

– Food machinery, metalworking machinery, etc.

Product types

Standard model

Standard Lifter Specifications List

| 750 kg Type | 1,000 kg Type | 2,000 kg Type | |

|---|---|---|---|

| Lifting Weight | 750 kg | 1,000 kg | 2,000 kg |

| Lifting Speed | 30 m/min | 30 m/min | 30 m/min |

| Lifting Stroke | 1,000 mm | 1,500 mm | 1,500 mm |

| Height with Chain Stored | 350 mm | 370 mm | 540 mm |

| Table Width | 800 mm | 900 mm | 2,100 mm |

| Table Length | 1,600 mm | 2,350 mm | 2,350 mm |

*Low-floor models, externally mounted chain models, high-frequency models, compact models, and other models are also available. Contact us for more information.

Compact series

| Specifications | Lifting Weight | Lifting Stroke | Time per 500 mm | Table Size (W x L) |

|

|---|---|---|---|---|---|

| Lifting | Lowering | ||||

| Standard (Induction motor) |

50 kg | 500 mm | Min. 7.0 s | Min. 7.0 s | 540 x 300 mm |

| High-speed (Servo motor) |

20 kg | 500 mm | Min. 1.0 s | Min. 1.0 s | |