UNIMEC

APPLICATIONS

You maybe did not know that many activities of your everyday life have been made possible thanks to UNIMEC. Are you flying on a real Giant of the Skies? UNIMEC made possible its assembling. Are you watching an opera at the most famous and most important theatre in the world? The stage can move thanks to us. Are you on a big sailing boat? We can take the credit for its sailing stability. Are your goods being shipped in containers? It would be difficult without UNIMEC. Are you taking a train? UNIMEC made it possible to lift it for its maintenance. Would you like to get a clean energy? UNIMEC helps people having an ecological heart. Are you able to communicate to the antipodes? It is possible thanks to UNIMEC’s sat antennas. Are you drinking milk in a glass or from a cardboard packaging for alimentary use? If you could see how it has been made?

Did we excite your curiosity? Just have a look around you and you will discover a little bit of UNIMEC, discrete but present.

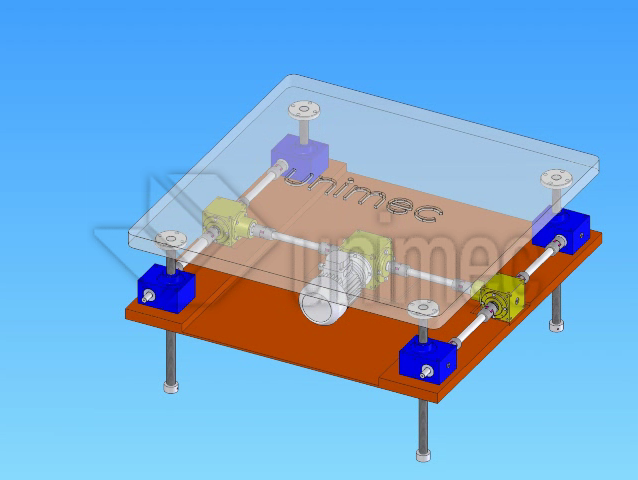

Platform

A platform is a flat which, usually, is moved on a vertical board by a specific lifting system. This could consist of pneumatic and mechanical screw jacks. Unimec encourages the use of its own mechanical screw jacks and bevel gear boxes: no compromise in quality and high precision. The choice of the mechanical screw jack isn’t occasional because it offers more advantages than others solutions thanks to its irreversibility. It allows, without any brake system, to maintain the correct position after the move. The lifting of a platform is realized by four Unimec screw jacks located in the four corners of the platform and linked together by couplings which allow the transmission of the power motion with perfect synchronism. For this kind of configuration, the flanged end fitting TF is a basic accessory : it is plugged on the trapezoidal spindle, in this case translation spindle, and consists of four o more holes (according to customers needs) and its size can change according to the loads. The platform’s dimension table is steadily fixed on the end fitting TF of the mechanical screw jack.

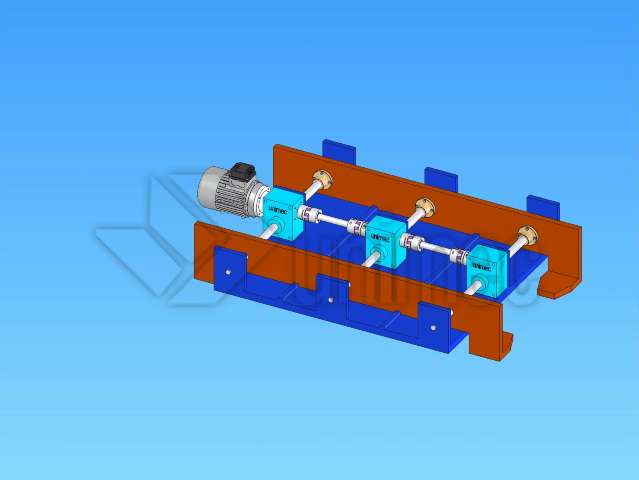

Fork

Fork is a system for the loads and materials handling. In this case the precision in synchronism represents an essential component for the mechanical handling of the plant. The mechanical screw jack used in forks is model TPR DA: the double action model satisfies the need to move two nuts with a unique kinematic. The threaded spindle protrudes from both screw faces and it has specific features; the configuration with the spindle is right threaded by one face and left threaded by other size. This allows, with unique kinematic, opposite shifts. Only one motor develops the transmission between the screw jacks as set mounted, and our couplings with high torsion stiffness allow the perfect synchronism of the input motion. All Unimec screw jacks could be arranged in double action model and standard rage is 1.000 Kg – 25.000 Kg.

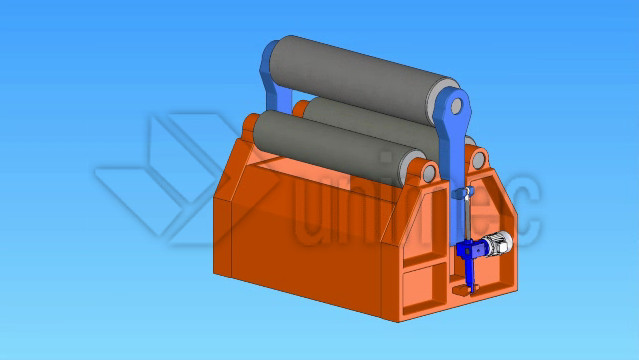

Bending machine

A bending machine is a tool machine which consists of two or more revolving cylinders, normally in steel or cast iron, between whom the materials to be worked passes. Bending machine is used in rubber industry, but also in paper , textile and metallurgic industries. Unimec screw jacks, thanks to their irreversibility, can move the higher roll guaranteeing in this way the prefect thick level of sheeted materials. For this application, the mechanical screw jack is better than the hydraulic one because the first doesn’t work with pressured lubrifications and this vanishes the risk of brake/cut of the seals or the capacity of the tube. Unimec projects involving bending machines prove that a standard doesn’t exist: the sizes of screw jacks start from a diameter of the trapezoidal spindle of 20×4 to the biggest, for example 80×10. Despite the high load to be lifted, the strategic assets for the correct use of the Unimec screw jacks in this application are linked to the precision used to move the roll up/down and the choice of the accessories, as you could see in the move, like rigid rocking protection and end fitting with hole in head that supports the roll movement. Input power is generated by a motor that is linked directly to the mechanical screw jack. Furthermore, it’s possible to set micro-regulations with the help of motoreducer and electronic control.

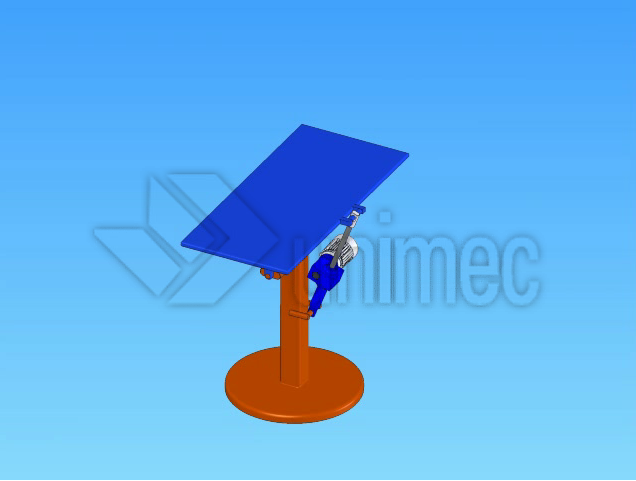

Solar Panel

A solar panel is a system that transforms solar energy into useful energy for human activities and, only in particular cases, into heat. Sunbeams reflect on a panel specifically orientated towards the sun and, thanks to special conductors, renewable energy is obtained (this features is possible thanks to the sun, an endless resource). The most important element to get maximum performance is the inclination of the panel. Since the efficiency of photovoltaic dell is higher when sunbeams impact against it perpendicularly, it’s necessary to arrange a system that can handle solar panel with the highest degree of accuracy and with the greatest mechanical strength. Unimec mechanical screw jack allows a movement of 90° or 180° during the day. This motion is realized by specific accessories as rocking rigid protection and end fitting TOR plugged on the translation spindle. Since Unimec screw jacks are situated in exterior environments, they are exposed to atmospheric agents; for this reason, it’s better to cover the spindle with rigid or elastic protections. In some cases we suggest also stainless mechanical screw jacks or screw jacks with stainless spindle.