GFA Series

Applications

- Digital cameras/cell phones

- Notebook PC/automobile resin parts

Comparison with general-purpose spray guns

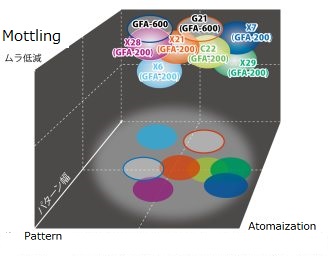

The GFA Series spray guns are designed with the focus on unevenness reduction.

The recent trends in resin coating paint are high brightness and high gloss. While paint contains many different pigments such as glass powder and evaporated metal, spray guns have come to be required to form a thinner film with a smaller spray volume, thus making the coating surface prone to become uneven. Conventional spray guns are unable to suppress such paint unevenness although they are versatile and capable of producing particles of small diameters.

Reducing unevenness does not necessarily mean higher atomization performance.

The important thing is where particles are distributed evenly in the pattern.

Structure and features

- High-density flat pattern

- Entire main body made of stainless steel

- Paint path structure with little paint accumulation

Thorough pursuit of unevenness reduction performance!

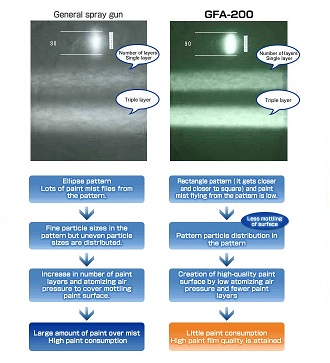

With general-purpose spray guns, unevenness or an irregular pattern results from thin-film, high-gloss coating with a small spray volume.

We have made thorough efforts to analyze the air flow of a spray gun and identify the causes of unevenness and eliminated those causes.

Reduction in paint consumption!

In most delivered lines, the finish quality is improved while paint consumption is reduced by 10% up to 50%.

* The reduction in the pass count due to reduced unevenness contributes more to the reduction in paint consumption than the improved transfer efficiency of the gun.

| Target workpiece | Coating | Effect |

|---|---|---|

| Cell phone main unit | Metallic/color clear coating | Reduction in paint consumption by 15 to 22% |

| LCD TV frame | Metallic coating | Reduction in paint consumption by 25% |

| AV equipment parts | Metallic coating | Reduction in paint consumption by 15 to 25% |

| Resin parts | Metallic coating | Reduction in paint consumption by 15 to 45% |

| Automobile exterior/corner bumpers | Metal-like coating | Automated hand gun line |

| Automobile exterior/rear garnish | Metallic/color clear/pearl coating | Reduction in cycle time by 50% |

GFA-200-084P

Small spray volume type

Applications: Robot coating, spindle coating, etc. for digital cameras and cell phones

GFA200S10C22-08

GFA-200-084P lightweight type

Applications: Twin-spin and other models with multiple spray guns mounted in a single coating robot

GFA200S2BX6-10

Medium spray volume type

Applications: Mask jig coating, metal coating, etc. for notebook PCs and automobile resin parts

GFA-600-122P

Medium spray volume type (with high unevenness reduction performance)

- Improved unevenness reduction performance

- Larger spray volume and greater pattern width

- Reduction in paint consumption

- High atomization performance

- High corrosion resistance (titanium used in the gun body)

- Target workpiece examples Bumper, spoiler, rear garnish

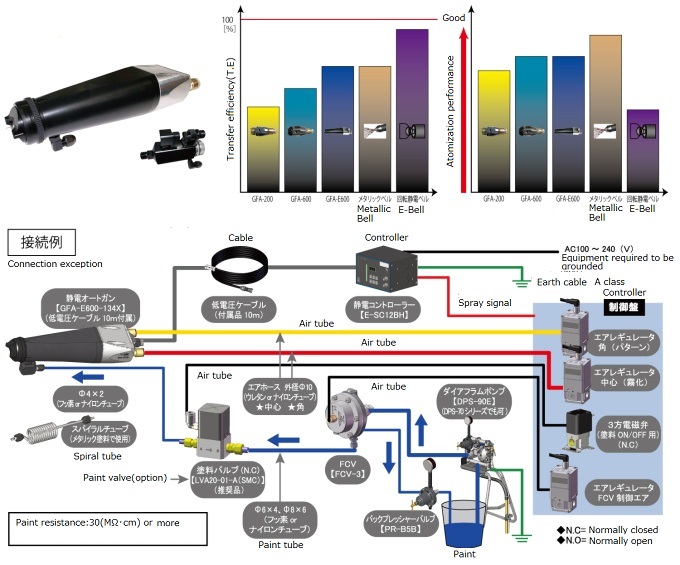

GFA-E600-134X

- Electrostatic effect is provided while maintaining the excellent design of the GFA Series.

- High transfer efficiency

- Support for water-based paint

- Mountable even on small robots

Accessories

| Model | Product name |

|---|---|

| 93542690 | GFA dedicated spanner |

| 93530691 | Paint adjusting unit protection cover |

| 93526690 | Dedicated paint joint |