IKEUCHI TF-PF

Air booster nozzles TAIFUJet® series(Long flat type)

| Spray pattern |

Flat |

Pipe conn. size |

1/2 – 1*1/2M |

| Standard pressure |

– |

Spray angle |

– |

| Spray capacity |

– |

Supply air type |

Compressed air |

Features

• Long flat air nozzle with 100 mm-1,400 mm in spray width.

• 13 spray width types are available.

• Max. allowable temperature: 400℃ (750゚F)

Applications

Blow-off drying: Blow-off drying after washing, Edge wiper for steel surface treatment, Blow-off drying for engine block

Blowing off dust/paint dust/debris, Blowing off inferior products (rejection of inferior products)

Cooling: Pinpoint cooling for molded plastic Others: Detachment, Cleaning, etc.

Industries in which this nozzle is used

Steelmaking, Machinery, Electronics, Paper & Pulp, Printing, Food, Automotives

Product specifications

| Structure |

• Long flat type air nozzles with 100 mm-1,400 mm in width and 40-546 orifices.

• Air inlet connection at both ends available for size 500 mm and longer. |

| Material |

S304

|

| Mass |

| Connection type |

Nozzle code |

Pipe connection size |

Mass(g) |

| One-end |

100-40-010 |

1/2M |

360 |

| 150-58-010 |

500 |

| 200-78-010 |

640 |

| 300-118-010 |

850 |

| 400-156-010 |

1,100 |

| 500-196-010 |

3/4M |

2,000 |

| 600-234-010 |

2,400 |

| 700-274-010 |

2,800 |

| 800-312-010 |

1M |

3,200 |

| 900-352-010 |

5,100 |

| 1000-390-010 |

5,600 |

| 1200-468-010 |

6,700 |

| 1400-546-010 |

1*1/2M |

13,800 |

| Both-end |

500-196-010 |

2-1/2M |

1,750 |

| 600-234-010 |

2,050 |

| 700-274-010 |

2,400 |

| 800-312-010 |

2-3/4M |

3,250 |

| 900-352-010 |

3,650 |

| 1000-390-010 |

4,000 |

| 1200-468-010 |

4,750 |

| 1400-546-010 |

2-1M |

8,800 |

For both-end connection type, pipe connection size is indicated as the number of inlets” – “thread size”.”

|

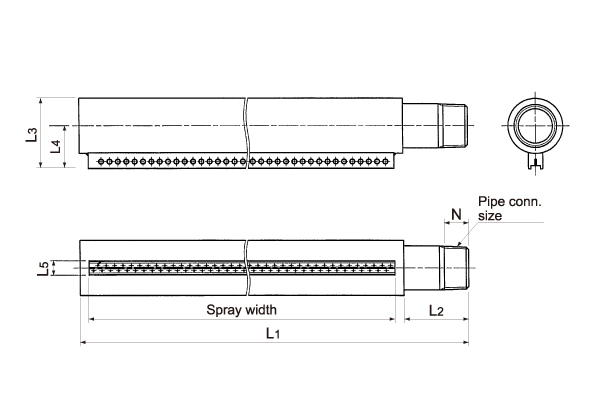

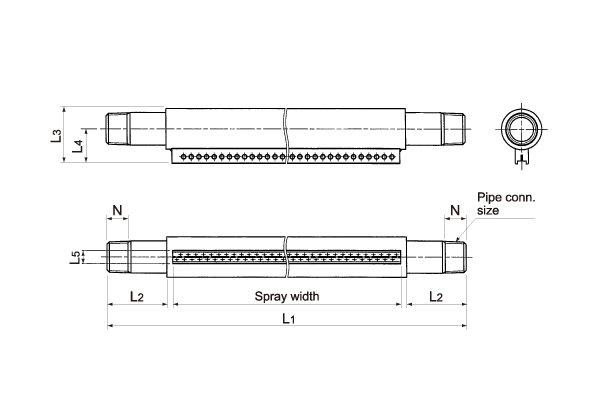

| Outer dimensions |

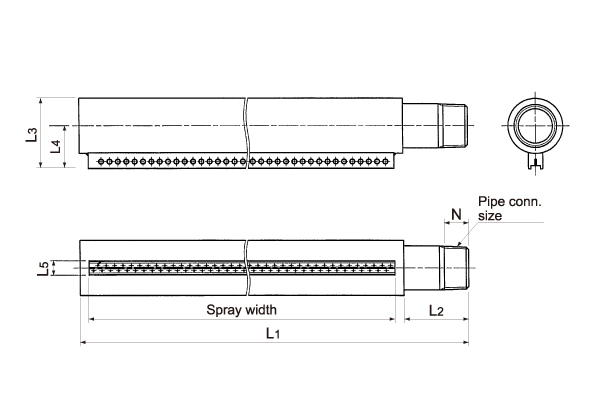

One-end connection type

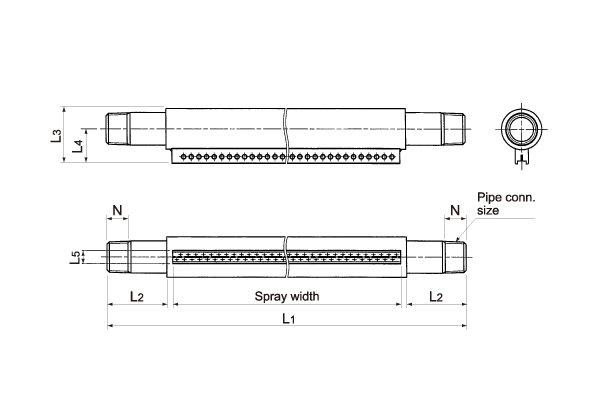

Both-end connection type

| Connection type |

Nozzle code |

Pipe conn. size |

Outer dimensions(mm) |

| L1 |

L2 |

L3 |

L4 |

L5 |

N |

| One-end |

100-40-010 |

1/2M |

156 |

40 |

37 |

23 |

9 |

14 |

| 150-58-010 |

203 |

40 |

37 |

23 |

9 |

14 |

| 200-78-010 |

254 |

40 |

37 |

23 |

9 |

14 |

| 300-118-010 |

357 |

40 |

37 |

23 |

9 |

14 |

| 400-156-010 |

455 |

40 |

37 |

23 |

9 |

14 |

| 500-196-010 |

3/4M |

557 |

40 |

44 |

27 |

9 |

15 |

| 600-234-010 |

655 |

40 |

44 |

27 |

9 |

15 |

| 700-274-010 |

758 |

40 |

44 |

27 |

9 |

15 |

| 800-312-010 |

1M |

856 |

40 |

52 |

31 |

9 |

18 |

| 900-352-010 |

959 |

40 |

52 |

31 |

9 |

18 |

| 1000-390-010 |

1,056 |

40 |

52 |

31 |

9 |

18 |

| 1200-468-010 |

1,257 |

40 |

52 |

31 |

9 |

18 |

| 1400-546-010 |

1*1/2M |

1,457 |

40 |

70 |

40 |

9 |

20 |

| Both-end |

500-196-010 |

2-1/2M |

597 |

40 |

37 |

23 |

9 |

14 |

| 600-234-010 |

695 |

40 |

37 |

23 |

9 |

14 |

| 700-274-010 |

798 |

40 |

37 |

23 |

9 |

14 |

| 800-312-010 |

2-3/4M |

896 |

40 |

44 |

27 |

9 |

15 |

| 900-352-010 |

999 |

40 |

44 |

27 |

9 |

15 |

| 1000-390-010 |

1,096 |

40 |

44 |

27 |

9 |

15 |

| 1200-468-010 |

1,297 |

40 |

44 |

27 |

9 |

15 |

| 1400-546-010 |

2-1M |

1,497 |

40 |

52 |

31 |

9 |

18 |

For both-end connection type, pipe connection size is indicated as “the number of inlets” – “thread size”.

• Appearance and dimensions may differ depending on materials and nozzle codes. Inquire with us for details.

|