Mitsubishi FR-F700PJ Series

Air conditioning inverter

Features

Suitable for both the general-purpose motor and the IPM motor

- This series can drive both a general-purpose motor and an IPM motor. Switching between the two motor controls is simple—just a single parameter setting. Initially, a general purpose motor could be used, then upgraded to an IPM motor without switching this inverter, leading to lower cost of equipment. (Compatible with the MM-EF series IPM motors.)

Environmentally friendly

- Power factor improving DC reactor, common mode choke (line noise filter), capacitive filter (radio noise filter) are all essential for air conditioning applications, and all of these are included in the Filterpack. The inverter with Filterpack is also available.

The wiring with different options is no longer required. - Less wiring and smaller space is required when Filterpack is used. Filterpack also enables compliance with the harmonic suppression guideline, the architectural standard specifications (electrical installation), and the architectural standard specifications (machinery installation) (2010 revisions) in Japan.

Easy-to-use

- The following functions provide the ideal operation for fans and pumps (PID control, Optimum excitation control, regeneration avoidance, and automatic restart after instantaneous power failure).

Improved reliability and easy maintenance

- Spring clamp terminals provide high reliability and easy wiring.

- The lives of the cooling fan and capacitor have been extended.

- Using the self-diagnosis function, the component life warning can be output and the degree of deterioration can be monitored to prevent malfunction.

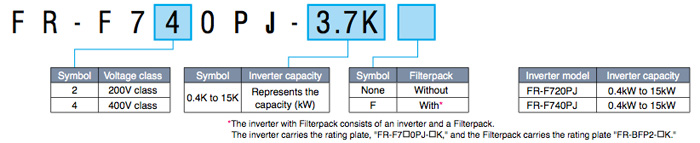

Model

Specifications

| Control method | Soft-PWM control, high carrier frequency PWM control (V/F control, General-purpose magnetic flux vector control, Optimum excitation control, and IPM motor control can be selected) | |

|---|---|---|

| Starting torque | General-purpose motor control | 120% (at 1Hz) with General-purpose magnetic flux vector control and slip compensation |

| IPM motor control | 50% | |

| Output frequency range | General-purpose motor control | 0.2 to 400Hz |

| IPM motor control | MM-EF : 0 to 135Hz | |

| Regenerative braking torque |

General-purpose motor control | 15% *1 |

| IPM motor control | 5% (10% for 1.5kW or lower) *1 | |

| Acceleration/deceleration time setting | 0.1 to 3600s (up to two types of accelerations and decelerations can be set individually.) | |

| Multi-speed | 15 speeds | |

| Speed command | 0 to 5VDC, 0 to 10VDC, 4 to 20mA, digital input with setting dial, digital setting with operation panel or parameter unit | |

| Alarm output | 1 changeover contact (230VAC 0.3A. 30VDC 0.3A), open collector output | |

| Output signal | One type of open collector output and one type of contact output (1 changeover contact) can be selected from inverter running, up to frequency, frequency detection, output current detection, operation ready, overload warning, fault output, and alarm, etc. | |

| Monitor function | One monitored item can be selected from output frequency, motor current (steady or peak value), output voltage, frequency setting value, converter output voltage, regenerative brake duty, and output power, etc. Pulse train output (1440 pulses/s 1mA) | |

| Restart after instantaneous power failure | Available (reduced voltage method (frequency search selectable)) | |

| Communication function | RS-485 supported (Modbus-RTU) as standard | |

*1: Regenerative braking torque is the average short-time torque when a motor decelerates to a stop from the rated speed in the shortest time. (It varies with the motor loss.) It is not a continuous regenerative torque. The average deceleration torque becomes lower when a motor decelerates from a speed higher than the rated speed.When the regenerative power is large, use a braking option.