SNSX-109

Socket Head Cap Screws – High Intensity S.S.

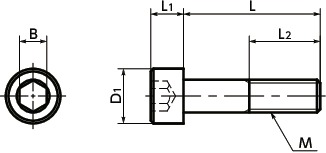

Dimension Drawing

Dimensions/Specifications/CAD

| Part Num+A104:L124ber | M | L | Strength Class | D1 | L1 | B | L2 | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SNSX-M6-16-109 | 6 | 16 | 10.9 | 10 | 6 | 5 | Full Thread | 1 | 5.8 |

| SNSX-M6-20-109 | 6 | 20 | 10.9 | 10 | 6 | 5 | Full Thread | 1 | 6.5 |

| SNSX-M6-25-109 | 6 | 25 | 10.9 | 10 | 6 | 5 | Full Thread | 1 | 7.6 |

| SNSX-M6-30-109 | 6 | 30 | 10.9 | 10 | 6 | 5 | Full Thread | 1 | 8.3 |

| SNSX-M6-40-109 | 6 | 40 | 10.9 | 10 | 6 | 5 | 24 | 1 | 11 |

| SNSX-M6-50-109 | 6 | 50 | 10.9 | 10 | 6 | 5 | 24 | 1 | 13 |

| SNSX-M8-16-109 | 8 | 16 | 10.9 | 13 | 8 | 6 | Full Thread | 1 | 12 |

| SNSX-M8-20-109 | 8 | 20 | 10.9 | 13 | 8 | 6 | Full Thread | 1 | 13 |

| SNSX-M8-25-109 | 8 | 25 | 10.9 | 13 | 8 | 6 | Full Thread | 1 | 15 |

| SNSX-M8-30-109 | 8 | 30 | 10.9 | 13 | 8 | 6 | Full Thread | 1 | 17 |

| SNSX-M8-40-109 | 8 | 40 | 10.9 | 13 | 8 | 6 | 28 | 1 | 21 |

| SNSX-M8-50-109 | 8 | 50 | 10.9 | 13 | 8 | 6 | 28 | 1 | 25 |

| SNSX-M10-20-109 | 10 | 20 | 10.9 | 16 | 10 | 8 | Full Thread | 1 | 23 |

| SNSX-M10-25-109 | 10 | 25 | 10.9 | 16 | 10 | 8 | Full Thread | 1 | 25 |

| SNSX-M10-30-109 | 10 | 30 | 10.9 | 16 | 10 | 8 | Full Thread | 1 | 28 |

| SNSX-M10-40-109 | 10 | 40 | 10.9 | 16 | 10 | 8 | Full Thread | 1 | 33 |

| SNSX-M10-50-109 | 10 | 50 | 10.9 | 16 | 10 | 8 | 32 | 1 | 39 |

| SNSX-M12-30-109 | 12 | 30 | 10.9 | 18 | 12 | 10 | Full Thread | 1 | 39 |

| SNSX-M12-40-109 | 12 | 40 | 10.9 | 18 | 12 | 10 | Full Thread | 1 | 47 |

| SNSX-M12-50-109 | 12 | 50 | 10.9 | 18 | 12 | 10 | Full Thread | 1 | 55 |

*If the“ L” value is other than the value in parentheses, the screw is full thread.

Material/Finish

| SNSX-88 | SNSX-109 | |

|---|---|---|

| Main Body | SUS316L HiMo | SUS316L HiMo |

| Strength Class | 8.8 | 10.9 |

Application

FPD production equipment, semiconductor devices, sputtering

equipment, aquatic applications, and general industrial machines

Characteristics

- High intensity socket head cap screws are made of stainless steel. (Strength Class 8.8 or 10.9)

- For applications that require both high strength and corrosion resistance.

- High strength per a screw is useful for space and weight saving by decreasing thread diameter and number.

- Screws with excellent heat resistance and corrosion resistance.

- Nonmagnetic.

Mechanical property

| Part Number・Strength Class\Property | Tensile Strength (N/mm2) | Proof Stress (N/mm2) | Elongation after Break Minimum (mm) |

|---|---|---|---|

| A2-50・A4-50 | 500 | 210 | 0.6d |

| A2-70・A4-70 | 700 | 450 | 0.4d |

| SNSX-888.8 | 800 | 640 | 0.3d |

| SNSX-10910.9 | 1,000 | 900 | 0.2d |

Values in chart are for reference only. They are not guaranteed values.

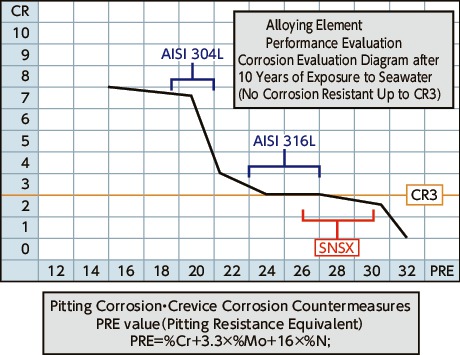

Result of corrosion test by metal materials

SUS316L HiMo steel used in SNSX is a special steel alloy with reduced carbon and increased Cr, Ni, and Mo. Reducing carbon shows an increased resistance to grain boundary corrosion cracking, and adding Cr and Mo increases resistance to pitting corrosion and crevice corrosion. In addition, adding Ni effectively reduces the risk of stress corrosion cracking.

The chart above shows the degree of corrosion after 10 years of exposure to conditions similar to seawater environment, and there was no corrosion for CR3 or lower.

Sulfuric acid corrosion test (H2SO4, 50°C and mm / year)

| Part Number・Material\Density | 3% | 10% | 20% |

|---|---|---|---|

| SUS304 | 1.08 | 3 | – |

| SUS316、SUS316L | 0 | 0.3 | 1.3 |

| SNSX-88 SNSX-109 | 0 | 0 | 0.44 |

Values in chart are for reference only. They are not guaranteed values.

Magnetic permeability comparison

| Part Number・Material | Amplitude Permeability |

|---|---|

| SNSX-88SUS316L HiMo | 1.006 |

| SNSX-109SUS316L HiMo | 1.007 |

| SNSLSUS316L | 1.015 |

| SUSXM7 | 1.4 |

Values in chart are for reference only. They are not guaranteed values.