SPE-P

Plastic Screws – Cross Recessed Pan Head Machine Screws – PEEK

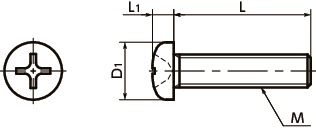

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | Tension Rupture Load(N)* | Torsional Torque (N・m)* | Qty per Pack |

|---|---|---|---|---|---|---|---|

| SPE-M1.7-4-P | 1.7 | 4 | 2.5 | 0.5 | 59 | 0.02 | 20 |

| SPE-M2-4-P | 2 | 4 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2-5-P | 2 | 5 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2-6-P | 2 | 6 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2-8-P | 2 | 8 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2-10-P | 2 | 10 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2-12-P | 2 | 12 | 3.5 | 1.3 | 160 | 0.06 | 20 |

| SPE-M2.6-6-P | 2.6 | 6 | 4.5 | 1.7 | 312 | 0.16 | 20 |

| SPE-M2.6-8-P | 2.6 | 8 | 4.5 | 1.7 | 312 | 0.16 | 20 |

| SPE-M2.6-10-P | 2.6 | 10 | 4.5 | 1.7 | 312 | 0.16 | 20 |

| SPE-M2.6-12-P | 2.6 | 12 | 4.5 | 1.7 | 312 | 0.16 | 20 |

| SPE-M3-5-P | 3 | 5 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-6-P | 3 | 6 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-8-P | 3 | 8 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-10-P | 3 | 10 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-12-P | 3 | 12 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-15-P | 3 | 15 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-16-P | 3 | 16 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-20-P | 3 | 20 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M3-25-P | 3 | 25 | 5.5 | 2 | 430 | 0.3 | 20 |

| SPE-M4-6-P | 4 | 6 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-8-P | 4 | 8 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-10-P | 4 | 10 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-12-P | 4 | 12 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-15-P | 4 | 15 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-16-P | 4 | 16 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-20-P | 4 | 20 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-25-P | 4 | 25 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M4-30-P | 4 | 30 | 7 | 2.6 | 765 | 0.64 | 20 |

| SPE-M5-6-P | 5 | 6 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-8-P | 5 | 8 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-10-P | 5 | 10 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-12-P | 5 | 12 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-15-P | 5 | 15 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-16-P | 5 | 16 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-20-P | 5 | 20 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-25-P | 5 | 25 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M5-30-P | 5 | 30 | 9 | 3.3 | 1230 | 1.28 | 10 |

| SPE-M6-10-P | 6 | 10 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M6-12-P | 6 | 12 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M6-15-P | 6 | 15 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M6-20-P | 6 | 20 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M6-25-P | 6 | 25 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M6-30-P | 6 | 30 | 10.5 | 3.9 | 1670 | 2.26 | 10 |

| SPE-M8-15-P | 8 | 15 | 14 | 5.2 | 3090 | 5.98 | 5 |

| SPE-M8-20-P | 8 | 20 | 14 | 5.2 | 3090 | 5.98 | 5 |

| SPE-M8-25-P | 8 | 25 | 14 | 5.2 | 3090 | 5.98 | 5 |

* Values in chart are for reference only. They are not guaranteed values.The recommendation torque is 50% of the torsional torque.

Material/Finish

| SPE-P | |

|---|---|

| Main body | PEEK/Light brown |

| Heat Resistance Temperature* | 180℃ |

*This is the value for the plastic material. The maximum operating temperature of the product changes with performance conditions such as tightening torque.

Application

FPD production equipment, semiconductor devices, printed

circuit board etching devices, metallic surface treatment

equipment and facilities, chemical plants, transformers, electrical

and electronic equipment, hot water pumps, and chemical pumps

Characteristics

- PEEK is a thermoplastic super-engineering plastic with excellent physical and chemical properties.

- These screws have excellent chemical resistance. They are mostly unaffected by chemicals excluding concentrate sulfuric acid, concentrate nitric acid, and concentrate hydrofluoric acid.

- These screws have excellent heat resistance, water resistance, and high heat resistance strength.

- These screws have excellent abrasion, shock, and fatigue resistance.

- They have high incombustibility that meets V-0 of UL 94.

- The properties and precautions of plastic screws

Because a cumulative pitch difference is created when PEEK screws are manufactured, use these screws with nuts. If a nut is not used, use a 20 mm or less fit with female thread.