SPV-C

Plastic Screw – Socket Head Cap Screws – PVDF

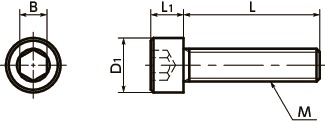

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Tension Rupture Load (N)* | Torsional Torque (N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SPV-M5-10-C | 5 | 10 | 8.5 | 5 | 4 | 640 | 0.64 | 20 | 0.62 |

| SPV-M5-15-C | 5 | 15 | 8.5 | 5 | 4 | 640 | 0.64 | 20 | 0.79 |

| SPV-M5-20-C | 5 | 20 | 8.5 | 5 | 4 | 640 | 0.64 | 20 | 0.92 |

| SPV-M5-25-C | 5 | 25 | 8.5 | 5 | 4 | 640 | 0.64 | 20 | 1.1 |

| SPV-M5-30-C | 5 | 30 | 8.5 | 5 | 4 | 640 | 0.64 | 20 | 1.3 |

| SPV-M6-10-C | 6 | 10 | 10 | 6 | 5 | 940 | 0.88 | 10 | 1.1 |

| SPV-M6-15-C | 6 | 15 | 10 | 6 | 5 | 940 | 0.88 | 10 | 1.3 |

| SPV-M6-20-C | 6 | 20 | 10 | 6 | 5 | 940 | 0.88 | 10 | 1.5 |

| SPV-M6-25-C | 6 | 25 | 10 | 6 | 5 | 940 | 0.88 | 10 | 1.7 |

* Values in chart are for reference only. They are not guaranteed values.The recommendation torque is 50% of the torsional torque.

Material/Finish

| SPV-C | |

|---|---|

| Main body | PVDF(Polyvinylidene fluoride)/Milky white |

| Heat resistance temperature* | 150℃ |

*This is the value for the plastic material. The maximum operating temperature of the product changes with performance conditions such as tightening torque.

Application

FPD production equipment, semiconductor devices, printed

circuit board etching devices, metallic surface treatment

equipment and facilities, chemical plants, and food industry

machines

Characteristics

- PVDF has excellent corrosion resistance against strong acids and organic solvents as well as halogen compounds such as hydrogen sulfide and bromine.

- It can be used in atmospheres in which metal and PVC (polyvinyl chloride)cannot be used.

- Max. Operating Temperature* (min./max.):

40/150 deg C - Its tensile strength equals or exceeds PVC, and its impact strength is 3 times that of PVC.

- These screws comply with food hygiene laws. It is proven to be nontoxic and odorless.

- It is self-extinguishing and has excellent incombustibility.

- The properties and precautions of plastic screws