SNPT

Cross Recessed Pan Head Machine Screws – Titanium

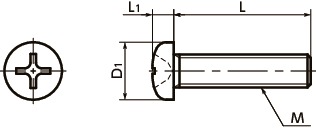

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | Tension Rupture Load (N)* | Torsional Torque(N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|

| SNPT-M2-5 | 2 | 5 | 3.5 | 1.3 | 840 | 0.3 | 1 | 0.09 |

| SNPT-M2-6 | 2 | 6 | 3.5 | 1.3 | 840 | 0.3 | 1 | 0.1 |

| SNPT-M2-8 | 2 | 8 | 3.5 | 1.3 | 840 | 0.3 | 1 | 0.12 |

| SNPT-M2-10 | 2 | 10 | 3.5 | 1.3 | 840 | 0.3 | 1 | 0.14 |

| SNPT-M2.5-5 | 2.5 | 5 | 4.5 | 1.7 | 1380 | 0.5 | 1 | 0.17 |

| SNPT-M2.5-6 | 2.5 | 6 | 4.5 | 1.7 | 1380 | 0.5 | 1 | 0.19 |

| SNPT-M2.5-8 | 2.5 | 8 | 4.5 | 1.7 | 1380 | 0.5 | 1 | 0.23 |

| SNPT-M2.5-10 | 2.5 | 10 | 4.5 | 1.7 | 1380 | 0.5 | 1 | 0.27 |

| SNPT-M2.5-12 | 2.5 | 12 | 4.5 | 1.7 | 1380 | 0.5 | 1 | 0.3 |

| SNPT-M3-6 | 3 | 6 | 5.5 | 2 | 2360 | 1 | 1 | 0.31 |

| SNPT-M3-8 | 3 | 8 | 5.5 | 2 | 2360 | 1 | 1 | 0.35 |

| SNPT-M3-10 | 3 | 10 | 5.5 | 2 | 2360 | 1 | 1 | 0.4 |

| SNPT-M3-12 | 3 | 12 | 5.5 | 2 | 2360 | 1 | 1 | 0.44 |

| SNPT-M3-16 | 3 | 16 | 5.5 | 2 | 2360 | 1 | 1 | 0.54 |

| SNPT-M3-20 | 3 | 20 | 5.5 | 2 | 2360 | 1 | 1 | 0.63 |

| SNPT-M4-6 | 4 | 6 | 7 | 2.6 | 4120 | 2.4 | 1 | 0.59 |

| SNPT-M4-8 | 4 | 8 | 7 | 2.6 | 4120 | 2.4 | 1 | 0.68 |

| SNPT-M4-10 | 4 | 10 | 7 | 2.6 | 4120 | 2.4 | 1 | 0.77 |

| SNPT-M4-12 | 4 | 12 | 7 | 2.6 | 4120 | 2.4 | 1 | 0.86 |

| SNPT-M4-16 | 4 | 16 | 7 | 2.6 | 4120 | 2.4 | 1 | 1 |

| SNPT-M4-20 | 4 | 20 | 7 | 2.6 | 4120 | 2.4 | 1 | 1.2 |

| SNPT-M4-25 | 4 | 25 | 7 | 2.6 | 4120 | 2.4 | 1 | 1.4 |

| SNPT-M5-8 | 5 | 8 | 9 | 3.3 | 6670 | 5.1 | 1 | 1.3 |

| SNPT-M5-10 | 5 | 10 | 9 | 3.3 | 6670 | 5.1 | 1 | 1.4 |

| SNPT-M5-12 | 5 | 12 | 9 | 3.3 | 6670 | 5.1 | 1 | 1.5 |

| SNPT-M5-16 | 5 | 16 | 9 | 3.3 | 6670 | 5.1 | 1 | 1.8 |

| SNPT-M5-20 | 5 | 20 | 9 | 3.3 | 6670 | 5.1 | 1 | 2.1 |

| SNPT-M5-25 | 5 | 25 | 9 | 3.3 | 6670 | 5.1 | 1 | 2.4 |

| SNPT-M5-30 | 5 | 30 | 9 | 3.3 | 6670 | 5.1 | 1 | 2.8 |

* Values in chart are for reference only. They are not guaranteed values.

Material/Finish

| SNPT | |

|---|---|

| Main Body | TW270(Grade 1 Titanium) |

Application

Lightweight applications in automobiles, aircrafts, spacecrafts, and robots

FPD production equipment, semiconductor devices, electrical and

electronic equipment, aquatic applications, and electrochemical plating

Characteristics

- Specific gravity is approximately 60% of stainless steel.

- Nonmagnetic.

- Excellent chemical and seawater resistance.

- Chemical polishing and brightening processing improve the screw surface. Furthermore, the screws are cleanroom washed, cleanroom packed, and comply with clean specifications that require no oil or foreign matter deposits.

- About the features of titanium⇒Properties of Titanium

Physical property

| TW270(Grade 1 Titanium) | |

|---|---|

| Specific Gravity | 4.51 |

| Melting Point(℃) | 1668 |

| Longitudinal Elastic Modulus(GPa) | 106 |

| Thermal Conductivity(W/(m・K)) | 17.16 |

| Linear Expansion Coefficient(K-1) | 8.4×10-6 |

| Electric Resistance(μΩ・m) | 0.55 |

| Amplitude Permeability(μ) | 1.0001(Nonmagnetic) |

Values in chart are for reference only. They are not guaranteed values.

Mechanical property

| TW270(Grade 1 Titanium) | |

|---|---|

| Tensile Strength(N/mm2) | 270-410 |

| 0.2% Proof Stress(N/mm2) | 165 or Higher |

| Elongation(%) | 27 or Higher |

Values in chart are for reference only. They are not guaranteed values.