SNST

Socket Head Cap Screws – Titanium

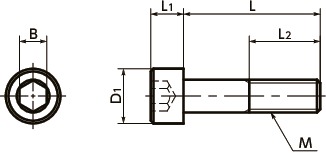

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | L2 | Tension Rupture Load | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SNST-M3-5 | 3 | 5 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.38 |

| SNST-M3-6 | 3 | 6 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.4 |

| SNST-M3-8 | 3 | 8 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.45 |

| SNST-M3-10 | 3 | 10 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.5 |

| SNST-M3-12 | 3 | 12 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.54 |

| SNST-M3-16 | 3 | 16 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.66 |

| SNST-M3-20 | 3 | 20 | 5.5 | 3 | 2.5 | Full Thread | 3210 | 1 | 0.77 |

| SNST-M4-8 | 4 | 8 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 0.94 |

| SNST-M4-10 | 4 | 10 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 1 |

| SNST-M4-12 | 4 | 12 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 1.1 |

| SNST-M4-16 | 4 | 16 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 1.3 |

| SNST-M4-20 | 4 | 20 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 1.5 |

| SNST-M4-25 | 4 | 25 | 7 | 4 | 3 | Full Thread | 5610 | 1 | 1.8 |

| SNST-M4-30 | 4 | 30 | 7 | 4 | 3 | 20 | 5610 | 1 | 2.1 |

| SNST-M5-10 | 5 | 10 | 8.5 | 5 | 4 | Full Thread | 9080 | 1 | 1.5 |

| SNST-M5-12 | 5 | 12 | 8.5 | 5 | 4 | Full Thread | 9080 | 1 | 1.7 |

| SNST-M5-16 | 5 | 16 | 8.5 | 5 | 4 | Full Thread | 9080 | 1 | 2 |

| SNST-M5-20 | 5 | 20 | 8.5 | 5 | 4 | Full Thread | 9080 | 1 | 2.3 |

| SNST-M5-25 | 5 | 25 | 8.5 | 5 | 4 | Full Thread | 9080 | 1 | 2.7 |

| SNST-M5-30 | 5 | 30 | 8.5 | 5 | 4 | 22 | 9080 | 1 | 3.1 |

| SNST-M5-35 | 5 | 35 | 8.5 | 5 | 4 | 22 | 9080 | 1 | 3.6 |

| SNST-M6-10 | 6 | 10 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 2.7 |

| SNST-M6-12 | 6 | 12 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 2.9 |

| SNST-M6-16 | 6 | 16 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 3.3 |

| SNST-M6-20 | 6 | 20 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 3.7 |

| SNST-M6-25 | 6 | 25 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 4.3 |

| SNST-M6-30 | 6 | 30 | 10 | 6 | 5 | Full Thread | 12800 | 1 | 4.7 |

| SNST-M6-35 | 6 | 35 | 10 | 6 | 5 | 24 | 12800 | 1 | 5.6 |

| SNST-M6-40 | 6 | 40 | 10 | 6 | 5 | 24 | 12800 | 1 | 6.2 |

| SNST-M6-45 | 6 | 45 | 10 | 6 | 5 | 24 | 12800 | 1 | 6.9 |

| SNST-M6-50 | 6 | 50 | 10 | 6 | 5 | 24 | 12800 | 1 | 7.5 |

* Values in chart are for reference only. They are not guaranteed values.

Material/Finish

| SNST | |

|---|---|

| Main Body | TB340C(Grade 2 Titanium) |

Application

Lightweight applications in automobiles, aircrafts, spacecrafts, and robots

FPD production equipment, semiconductor devices, electrical and electronic

equipment, aquatic applications, and electrochemical plating

Characteristics

- Specific gravity is approximately by 60% of stainless steel.

- Nonmagnetic.

- Excellent chemical and seawater resistance.

- About the features of titanium⇒Properties of Titanium

- Chemical polishing and brightening processing improve the screw surface. Furthermore, the screws are cleanroom washed, cleanroom packed, and comply with clean specifications that require no oil or foreign matter deposits.

Physical property

| TB340C(Grade 2 Titanium) | |

|---|---|

| Specific Gravity | 4.51 |

| Melting Point(℃) | 1668 |

| Longitudinal Elastic Modulus(GPa) | 106 |

| Thermal Conductivity(W/(m・K)) | 17.16 |

| Linear Expansion Coefficient(K-1) | 8.4×10-6 |

| Electric Resistance(μΩ・m) | 0.55 |

| Amplitude Permeability(μ) | 1.0001(Nonmagnetic) |

Values in chart are for reference only. They are not guaranteed values.

Mechanical property

| TB340C(Grade 2 Titanium) | |

|---|---|

| Tensile Strength(N/mm2) | 340-510 |

| 0.2% Proof Stress(N/mm2) | 215 or Higher |

| Elongation(%) | 23 or Higher |

Values in chart are for reference only. They are not guaranteed values.