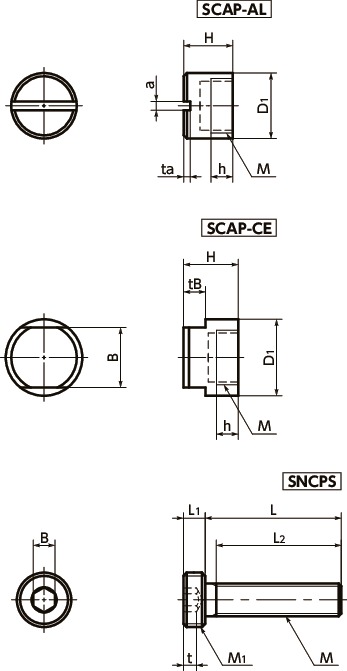

SCAP-CE

Cover Caps / Socket Head Cap Screws for Cover Caps

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | H | D1 | h | B | tB | Recommended Torque (N・m) | SCAP Part No. | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|---|

| SCAP-3-CE | 5×0.5 | 6 | 9 | 2 | 7 | 3 | 0.1 | SNCPS-M3 | 1 | 1.2 |

| SCAP-4-CE | 6×0.75 | 8 | 10 | 2.8 | 8 | 3 | 0.15 | SNCPS-M4 | 1 | 2 |

| SCAP-5-CE | 8×0.75 | 9 | 12 | 3.5 | 9 | 3 | 0.3 | SNCPS-M5 | 1 | 3 |

| SCAP-6-CE | 10×0.75 | 10 | 14 | 4 | 11 | 4 | 0.4 | SNCPS-M6 | 1 | 4.3 |

| SCAP-8-CE | 12×1 | 11 | 16 | 5 | 13 | 4 | 0.6 | SNCPS-M8 | 1 | 5.8 |

| SCAP-10-CE | 16×1 | 12 | 20 | 6 | 17 | 4 | 0.8 | SNCPS-M10 | 1 | 9.2 |

Material/Finish

| SCAP-AL Cover Caps | SCAP-CE Cover Caps | SNCPS Cap Screws | |

|---|---|---|---|

| Main Body | A5056 | Al2O3 (99.5% Alumina) | SUSXM7 (S.S. grade:A2) |

| Strength Class | A2-50 |

Application

Film formation equipment, etching devices, FPD production equipment, and semiconductor devices

Characteristics

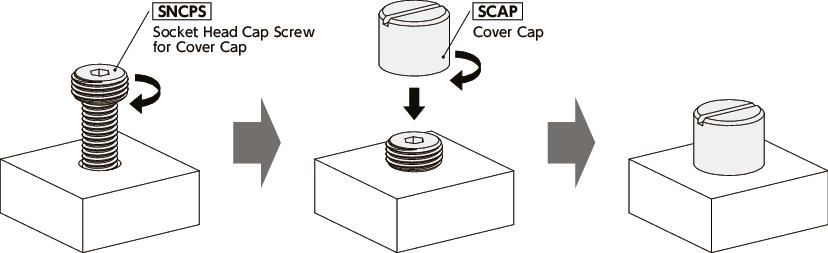

- Combine SCAP Cover Cap and SNCPS Socket Head Cap Screw for Cover Cap.

- These caps prevent the corrosion of screw heads due to vacuum chamber processing gas and plasma.

- SCAP has 2 material types as standard.

SCAP-AL—-Aluminum alloy

SCAP-CE—-Ceramic - The screw connection section is made of stainless steel, so this product has a higher tightening strength than aluminum or ceramic screws.

- Other requested materials such as Inconel* and Hastelloy* can be used for Cover Caps.

*Inconel is a registered trademark of Special Metals Corporation.

*Hastelloy is a registered trademark of Haynes International, Inc.

Usage example

After tightening SNCPS Socket Head Cap Screw for Cover Cap, assemble SCAP Cover Cap so that it covers the head of SNCPS.

Ensure that the tightening torque of SCAP does not exceed the recommended torque in the chart.

Precautions for Use

Corrosion resistance changes depending on use conditions. Always carry out tests under conditions same as actual conditions before use.