SVSQS

Socket Head Cap Screws with Captive Washer and Ventilation Hole

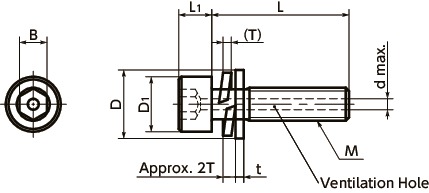

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | D | L1 | B | t | T (Approx.) | d max. | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SVSQS-M3-5 | 3 | 5 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 0.9 |

| SVSQS-M3-6 | 3 | 6 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 0.94 |

| SVSQS-M3-8 | 3 | 8 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 1 |

| SVSQS-M3-10 | 3 | 10 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 1.1 |

| SVSQS-M3-12 | 3 | 12 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 1.2 |

| SVSQS-M3-16 | 3 | 16 | 5.5 | 7 | 3 | 2.5 | 0.5 | 0.7 | 1.2 | 20 | 1.4 |

| SVSQS-M4-6 | 4 | 6 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 2.1 |

| SVSQS-M4-8 | 4 | 8 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 2.2 |

| SVSQS-M4-10 | 4 | 10 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 2.4 |

| SVSQS-M4-12 | 4 | 12 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 2.5 |

| SVSQS-M4-16 | 4 | 16 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 2.8 |

| SVSQS-M4-20 | 4 | 20 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 3.2 |

| SVSQS-M4-25 | 4 | 25 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 3.7 |

| SVSQS-M4-30 | 4 | 30 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 4.2 |

| SVSQS-M4-35 | 4 | 35 | 7 | 9 | 4 | 3 | 0.8 | 1 | 1.5 | 10 | 4.7 |

| SVSQS-M5-8 | 5 | 8 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 3.4 |

| SVSQS-M5-10 | 5 | 10 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 3.6 |

| SVSQS-M5-12 | 5 | 12 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 3.9 |

| SVSQS-M5-16 | 5 | 16 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 4.4 |

| SVSQS-M5-20 | 5 | 20 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 4.9 |

| SVSQS-M5-25 | 5 | 25 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 5.7 |

| SVSQS-M5-30 | 5 | 30 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 6.5 |

| SVSQS-M5-35 | 5 | 35 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 7.2 |

| SVSQS-M5-40 | 5 | 40 | 8.5 | 10 | 5 | 4 | 1 | 1.3 | 1.5 | 10 | 8 |

| SVSQS-M6-10 | 6 | 10 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 6.9 |

| SVSQS-M6-12 | 6 | 12 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 7.2 |

| SVSQS-M6-16 | 6 | 16 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 7.9 |

| SVSQS-M6-20 | 6 | 20 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 8.7 |

| SVSQS-M6-25 | 6 | 25 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 9.7 |

| SVSQS-M6-30 | 6 | 30 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 10 |

| SVSQS-M6-35 | 6 | 35 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 12 |

| SVSQS-M6-40 | 6 | 40 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 13 |

| SVSQS-M6-45 | 6 | 45 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 14 |

| SVSQS-M6-50 | 6 | 50 | 10 | 12.5 | 6 | 5 | 1.6 | 1.5 | 2 | 10 | 15 |

| SVSQS-M8-12 | 8 | 12 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 15 |

| SVSQS-M8-16 | 8 | 16 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 16 |

| SVSQS-M8-20 | 8 | 20 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 18 |

| SVSQS-M8-25 | 8 | 25 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 19 |

| SVSQS-M8-30 | 8 | 30 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 21 |

| SVSQS-M8-35 | 8 | 35 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 23 |

| SVSQS-M8-40 | 8 | 40 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 25 |

| SVSQS-M8-45 | 8 | 45 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 27 |

| SVSQS-M8-50 | 8 | 50 | 13 | 17 | 8 | 6 | 1.6 | 2 | 2 | 10 | 29 |

| SVSQS-M10-16 | 10 | 16 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 29 |

| SVSQS-M10-20 | 10 | 20 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 31 |

| SVSQS-M10-25 | 10 | 25 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 33 |

| SVSQS-M10-30 | 10 | 30 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 36 |

| SVSQS-M10-35 | 10 | 35 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 38 |

| SVSQS-M10-40 | 10 | 40 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 41 |

| SVSQS-M10-45 | 10 | 45 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 44 |

| SVSQS-M10-50 | 10 | 50 | 16 | 21 | 10 | 8 | 2 | 2.5 | 3 | 5 | 47 |

| SVSQS-M12-30 | 12 | 30 | 18 | 24 | 12 | 10 | 2.5 | 3 | 3 | 5 | 51 |

| SVSQS-M12-35 | 12 | 35 | 18 | 24 | 12 | 10 | 2.5 | 3 | 3 | 5 | 55 |

| SVSQS-M12-40 | 12 | 40 | 18 | 24 | 12 | 10 | 2.5 | 3 | 3 | 5 | 58 |

| SVSQS-M12-45 | 12 | 45 | 18 | 24 | 12 | 10 | 2.5 | 3 | 3 | 5 | 62 |

| SVSQS-M12-50 | 12 | 50 | 18 | 24 | 12 | 10 | 2.5 | 3 | 3 | 5 | 66 |

Material/Finish

| SVSQS | |

|---|---|

| Screw Body | SUSXM7(S.S. grade:A2) |

| Screw Body Tensile Strength | A2-70 |

| Washer | SUS304 |

| Spring Washer | SUS304 |

Application

Vacuum devices, vacuum chambers, FPD production equipment,

semiconductor devices, and electron microscopes

Characteristics

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

- Flat washers and spring washers are captive, therefore prevent separation from screws.

- It is unnecessary to assemble washers. It simplifies work when wearing gloves in a clean room.