SVSS-MOS

Socket Head Cap Screws with Ventilation Hole – MoS2 Shot

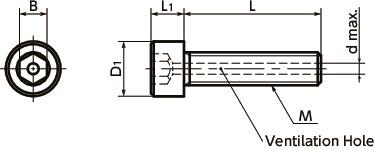

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | d max. | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|

| SVSS-M3-6-MOS | 3 | 6 | 5.5 | 3 | 2.5 | 1.2 | 20 | 0.71 |

| SVSS-M3-8-MOS | 3 | 8 | 5.5 | 3 | 2.5 | 1.2 | 20 | 0.8 |

| SVSS-M3-10-MOS | 3 | 10 | 5.5 | 3 | 2.5 | 1.2 | 20 | 0.88 |

| SVSS-M3-12-MOS | 3 | 12 | 5.5 | 3 | 2.5 | 1.2 | 20 | 0.96 |

| SVSS-M3-16-MOS | 3 | 16 | 5.5 | 3 | 2.5 | 1.2 | 20 | 1.2 |

| SVSS-M4-6-MOS | 4 | 6 | 7 | 4 | 3 | 1.5 | 10 | 1.5 |

| SVSS-M4-8-MOS | 4 | 8 | 7 | 4 | 3 | 1.5 | 10 | 1.7 |

| SVSS-M4-10-MOS | 4 | 10 | 7 | 4 | 3 | 1.5 | 10 | 1.8 |

| SVSS-M4-12-MOS | 4 | 12 | 7 | 4 | 3 | 1.5 | 10 | 2 |

| SVSS-M4-16-MOS | 4 | 16 | 7 | 4 | 3 | 1.5 | 10 | 2.3 |

| SVSS-M4-20-MOS | 4 | 20 | 7 | 4 | 3 | 1.5 | 10 | 2.7 |

| SVSS-M4-25-MOS | 4 | 25 | 7 | 4 | 3 | 1.5 | 10 | 3.2 |

| SVSS-M5-6-MOS | 5 | 6 | 8.5 | 5 | 4 | 1.5 | 10 | 2.2 |

| SVSS-M5-8-MOS | 5 | 8 | 8.5 | 5 | 4 | 1.5 | 10 | 2.5 |

| SVSS-M5-10-MOS | 5 | 10 | 8.5 | 5 | 4 | 1.5 | 10 | 2.7 |

| SVSS-M5-12-MOS | 5 | 12 | 8.5 | 5 | 4 | 1.5 | 10 | 3 |

| SVSS-M5-16-MOS | 5 | 16 | 8.5 | 5 | 4 | 1.5 | 10 | 3.5 |

| SVSS-M5-20-MOS | 5 | 20 | 8.5 | 5 | 4 | 1.5 | 10 | 4 |

| SVSS-M5-25-MOS | 5 | 25 | 8.5 | 5 | 4 | 1.5 | 10 | 4.8 |

| SVSS-M6-8-MOS | 6 | 8 | 10 | 6 | 5 | 2 | 10 | 4.3 |

| SVSS-M6-10-MOS | 6 | 10 | 10 | 6 | 5 | 2 | 10 | 4.7 |

| SVSS-M6-12-MOS | 6 | 12 | 10 | 6 | 5 | 2 | 10 | 5.1 |

| SVSS-M6-16-MOS | 6 | 16 | 10 | 6 | 5 | 2 | 10 | 5.8 |

| SVSS-M6-20-MOS | 6 | 20 | 10 | 6 | 5 | 2 | 10 | 6.5 |

| SVSS-M6-25-MOS | 6 | 25 | 10 | 6 | 5 | 2 | 10 | 7.6 |

| SVSS-M6-30-MOS | 6 | 30 | 10 | 6 | 5 | 2 | 10 | 8.3 |

| SVSS-M8-12-MOS | 8 | 12 | 13 | 8 | 6 | 2 | 10 | 11 |

| SVSS-M8-16-MOS | 8 | 16 | 13 | 8 | 6 | 2 | 10 | 12 |

| SVSS-M8-20-MOS | 8 | 20 | 13 | 8 | 6 | 2 | 10 | 13 |

| SVSS-M8-25-MOS | 8 | 25 | 13 | 8 | 6 | 2 | 10 | 15 |

| SVSS-M8-30-MOS | 8 | 30 | 13 | 8 | 6 | 2 | 10 | 17 |

| SVSS-M8-35-MOS | 8 | 35 | 13 | 8 | 6 | 2 | 10 | 19 |

Material/Finish

| SVSS-MOS | |

|---|---|

| Main Body | SUSXM7(S.S. grade:A2) MoS2 Shot |

| Strength Class | A2-70 |

Application

Seizing Prevention

Vacuum devices, vacuum chambers, FPD production equipment,

semiconductor devices, and electron microscopes

Characteristics

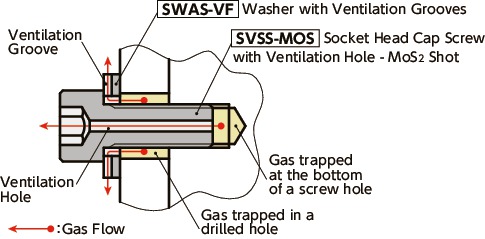

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

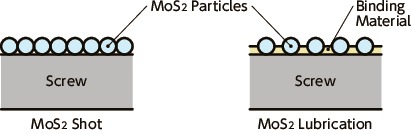

- The MoS2 particles shot by shot blast increase the lubrication of the screw and prevent seizing.

- Unlike a general MoS2 lubrication, MoS2 shot does not use a bonding agent so it is easy to identify contained materials.

Usage example

Gas trapped at the bottom of a screw hole is released through SVSS-MOS, and gas trapped in a drilled hole is released through SWAS-VF