High-Efficiency ARL Series MECHATROLINK-II-Compatible

- Incorporating Our Unique Closed Loop Control

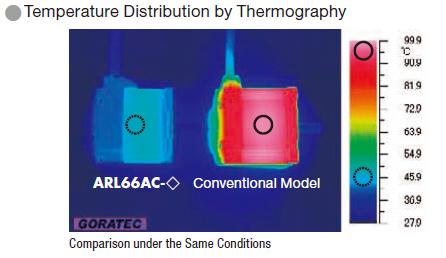

- Reduced Heat Generation by High-Efficiency Motor

- Lower Heat Generation

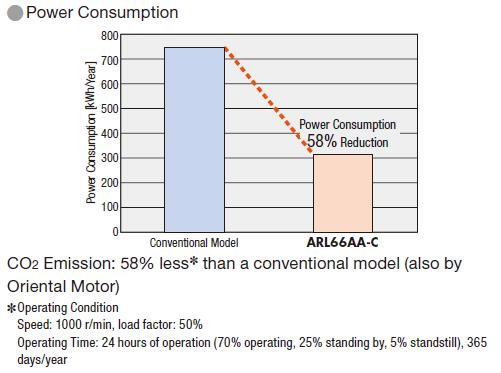

- Energy Savings

- Alarm Signal Output in Case of Abnormality

- Unique Advantages of Stepping Motors

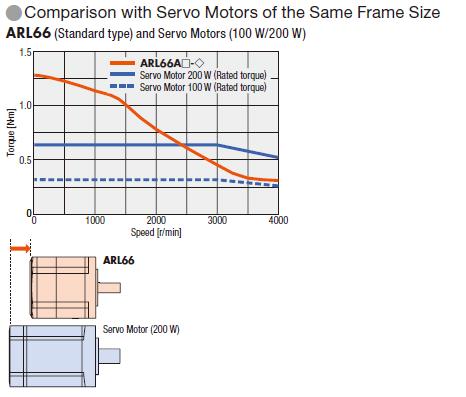

- Compact, yet High Torque

- User-Friendly and Easy, Highly Accurate Positioning

- High Response

- Capable of Driving Large Inertial Loads

- No Tuning

- Holding the Stop Position

- Also Supports Absolute Systems✽

The ARL Series utilizes high-efficiency technology to achieve a significant reduction in the amount of heat generated from the motor.

Power Consumption: 58% less ✽ than a conventional model (also by Oriental Motor)

If an overload is applied continuously, an alarm signal is output.

When the positioning is complete, an END signal is output. This ensures the same level of reliability achieved by a servo motor.

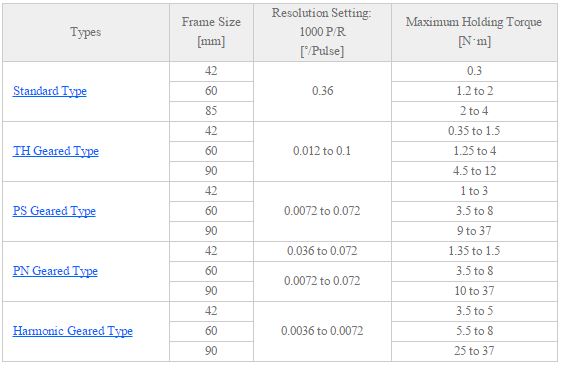

Stepping motors generate high torque with a compact body.

Since a stepping motor has a shorter overall length compared to a servo motor of the same frame size (also by Oriental Motor), the device space can be reduced.

Stepping motors provide convenient means to ensure highly accurate positioning because they synchronize themselves with commands without requiring feedback.

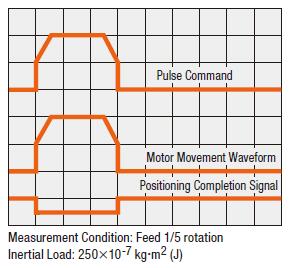

Since they operate synchronously with pulse commands and generate high torque with a compact body, stepping motors offer excellent acceleration performance and response.

They are ideal for applications requiring frequent starting and stopping.

Compared with a servo motor of the same frame size, a largerb inertial load can be driven regardless of speed conditions.

Positioning is still possible without gain tuning even when the load fluctuates due to use of a belt mechanism, cam or chain drive, etc.

During positioning, the motor stops with its own holding torque without hunting. Accordingly, stepping motors are ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stop.

You can build an absolute system that detects absolute positions by connecting the accessory battery (sold separately).

✽ Limited to CC-Link or MECHATROLINK- compatible built-in controller types.

CC-Link-Compatible (This is a motor and driver package product.)

This driver conforms with the field network system CC-Link. Up to 63 positioning data points can be stored to let you select a desired operation number directly from the programmable controller to operate the motor.

This feature is also convenient when rewriting data for the purpose of fine-tuning or monitoring position information.

Key Features

● Up to 63 Positioning Data Points

● Linked Operation

● Push-Motion Operation

● Smooth Drive Function to Achieve Low Vibration at Low Speed

● Absolute Mode

● Data Transfer

● Simple Wiring

● Distributed Layout

● Supports Teaching Pendants