FAYb Laser Marker for Semiconductor Packages LP-W

FDA Approved

FDA : Some models only

Features

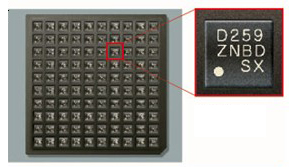

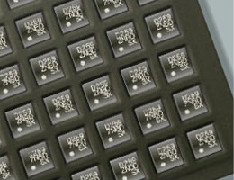

Clear marking

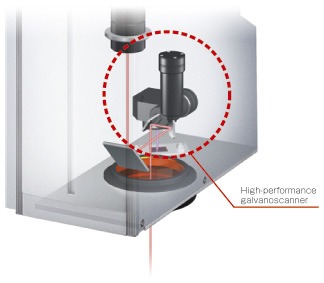

It’s critical that marking on low-profile electronic components such as chip-size packages has little effect on the target object. Laser output control and a hige-speed galvanoscanner make it possible to keep the marking depth to just 10 μm 0.4 mil or less

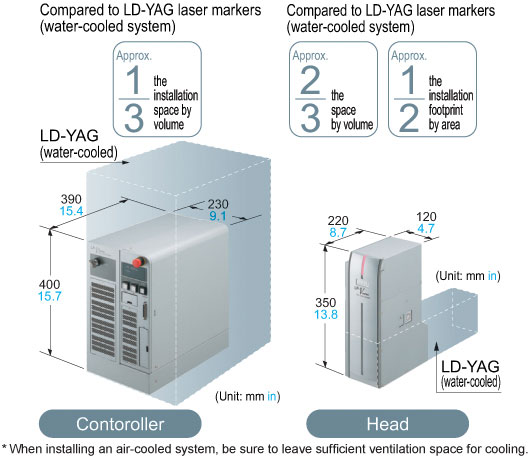

Completely air-cooled

By utilizing a heat-suppressing design with exceptional dissipation characteristics, Panasonic Industrial Devices SUNX was able to develop a completely air-cooled oscillator.

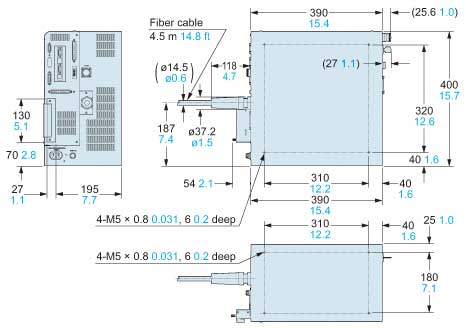

Space-saving design

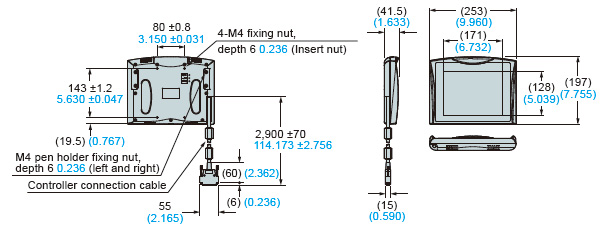

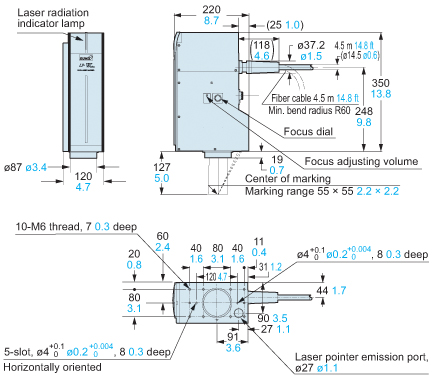

The system’s head has a footprint smaller than a B5 sheet of paper, and the adility to install it in any orientation ensures that no space will be wasted. The LP-W series systems are surprisingly compact since they don’t require coolant pipes or additional cooling equipment. The result is reduced equipment and deployment costs.

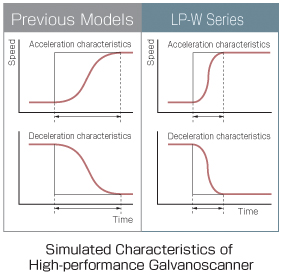

The LP-W series feature a hige-performance galvanoscanner whose acceleration, deceleration, and response speeds exceed those of previous models by at least 200%, delivering dramatically shorter marking tact times.

Easily set by using a computer with the “Laser Marker NAVI” software

The LP-W series come standard with application software for easily configuring print data.

Marking layout can be easily performed as desired with intuitive and simple mouse operations. Moreover, batch control of multiple laser markers is possible using one computer. This significantly contributes to increased work efficiency.

Laser Marker NAVI included softwares

Extraordinarily easy to use color LCD equipped console [LP-ADP40 (optional)]

A color touch panel designed for maximum ease of use and viewing provides stress-free operation by displaying marking data and settings immediately.

The LP-W series laser markers can be operated using a commercially-available monitor and mouse instead of console as equipped with the VGA connector and mouse connector.

Convenient features meet a variety of needs

- USB connectors

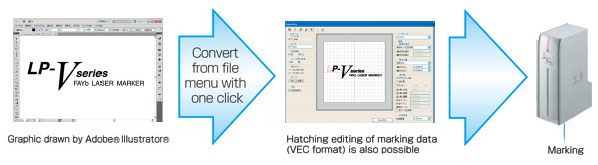

- Easy marking of Adobe® Illustrator® data

The ability to store system settings on standard USB memory sticks lets you backup marking settings or copy the same set of settings to multiple laser markers, delivering improved ease of use compared to the floppy disk drive used by previous models.

(The system also supports USB-connected floppy disk drives.)

Data created by Adobe® Illustrator® can be converted into marking data by “ExportVec”, which is a standard-included software. Logos or marks can be easily marked while staying true to the original Adobe® Illustrator® graphic images.

| Type | For semiconductor packages (small-spot type) | |

|---|---|---|

| Set model No. | LP-W052U | |

| Work distance (Note 1) | 127 mm 5.0 in | |

| Marking laser | Class 4 Yb fiber laser; wavelength: 1.06 ?m 0.042 mil | |

| Average output (Note 2) |

5 W (CW oscillation) | |

| Guide laser/pointer | Class 2 semiconductor laser; wavelength: 655 nm 0.026 mil | |

| Marking field | 55 x 55 mm 2.2 x 2.2 in | |

| Scan speed | Max. 6,000 mm/s | |

| Line speed (Note 3) | 120 m/min or less | |

| Installation orientation | All | |

| Character settings (character height, width) |

0.2 to 55 mm 0.008 to 2.2 in (variable in 0.001 mm 0.00004 in steps) |

|

| Marking spacing (character spacing, line pitch) |

0 to 55 mm 0 to 2.2 in (variable in 0.001 mm 0.00004 in steps) Arced output: -180? to +180? (variable in 0.01?steps) |

|

| Making shape | Straight Line, Arc, Proportional, Justify | |

| Character types | English uppercase letters, English lowercase letters, numerals, katakana, hiragana, kanji (JIS No. 1 and No. 2 standards), symbols, user-registered characters (up to 50) | |

| Barcodes | Code 39, Code 128, ITF, NW-7, JAN (EAN) / UPC, RSS-14 (GS1 DataBar), RSS (GS1 DataBar) Limited, RSS (GS1 DataBar) Expanded | |

| 2D codes | QR Code, Micro QR Code, Data Matrix, GS1 Data Matrix | |

| Composite codes | RSS-14 (GS1 DataBar) CC-A, RSS-14 (GS1 DataBar) Stacked CC-A, RSS (GS1 DataBar) Limited CC-A, etc. | |

| Logos / Shapes | VEC (Note 4), BMP, DXF, HPGL, JPEG, AI (Note 5), EPS (Note 5) | |

| Interface (Note 6) | RS-232C, Ethernet | |

| Cooling method | Forced air cooling | |

| Power supply | 90 to 132 V AC or 180 to 264 V AC (automatic switching),50/60 Hz | |

| Power consumption | 310 VA or less (100 V AC); 360 VA or less (200 V AC) | |

| Inputs | Remote, trigger, encoder (A), encoder (B), shutter control, laser excitation, alarm reset, emergency stop, laser stop, etc. | |

| Outputs | Power supply (+12 V), remote, marking ready, marking, marking complete, laser excitation, warning, alarm, configuration complete, counter complete | |

| Marking state | Still, moving | |

| Functions | +Marking order optimization | |

| +Intersection correction | ||

| +Counter marking | ||

| +Current date marking | ||

| +Deadline date marking | ||

| +Lot marking | ||

| +Logo data marking | ||

| +Font creation and editing | ||

| +Monospaced alignment | ||

| +Updating of operating screen display | ||

| +System offset | ||

| +Shared character settings | ||

| +Guide laser | ||

| +Dual pointers | ||

| +Overlapping marking | ||

| +Backup | ||

| +Marking on long moving objects | ||

| +Font selection | ||

| +Focus adjustment | ||

| +Proportional marking | ||

| +Marking image display | ||

| +Marking time measurement | ||

| +Target object image display | ||

| +Bold marking | ||

| +Rank marking | ||

| +Offset marking | ||

| +Time hold | ||

| +Step and repeat | ||

| +Operator adjustment | ||

| +I/O simulation | ||

| +Error log display | ||

| +Serial data marking | ||

| +Power check and correction | ||

| +I/O confirmation monitor | ||

| +Power and speed configuration by row or logo file | ||

| Emergency stop switch | Located on controller | |

| Ambient temperature | 0 to +40? +32 to +104? (Storage: -10 to +60 ? +14 to 140 ?) (non-condensing and non-freezing) |

|

| Ambient humidity | 35 % to 85 % RH (non-condensing and non-freezing) | |

| Net weight | Head | 9 kg |

| Controller | 22 kg | |

Notes:

1) Distance from target object varies by approx. ±2 mm ±0.079 in from model to model.

2) It is output of a laser oscillator.

3) Varies by target object.

4) VEC is a usable format of logo file for laser marker.

5) The PC installed Adobe Illustrator is necessary.

6) Ethernet has been changed from production in March 2013.

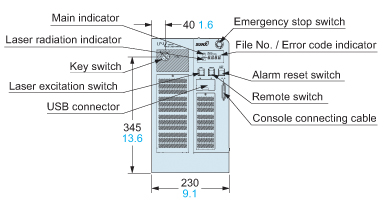

Controller

LP-W052U

Console