FAYb Laser Marker LP-S500W

A New Standard Black Laser Annealing

CE , FDA Approved

CE : Low Voltage Directive, EMC Directive

Features

The LP-S500W series is the culmination of technologies that have been developed over many years.

With its high output and newly developed optical system suited for black laser annealing, the FAYb* laser allows for quick and clear black laser annealing in a package that is easy to set up.

The LP-S500W series brings black laser annealing to a whole new level.

*FAYb: Fiber Amplified Ytterbium

SIMPLE

Black laser annealing made simple thanks to a newly developed optics design

Black laser annealing* oxidizes the surfaces of metals, turning them black.

To achieve the perfect black tone, strict optimizations were performed.

With the LP-S500W series, we have made black laser annealing simple thanks to a newly developed optics design.

Easy to configure, the LP-S500W allows beautiful, reliable black marking.

The latest in optical technology will improve quality and productivity.

*Optimal performance may not be achievable with certain materials.

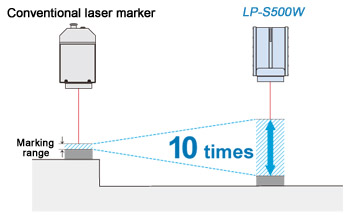

Reliable black laser annealing used to require strict management of the target’s work distance. With the LP-S500W series, you now have ±15 mm ±0.591 in* more flexibility in work distance thanks to a newly developed optics design. There is no longer a need to do process changeovers for lines producing products of different sizes. And, because printing is done uniformly regardless of height differences, the LP-S500W series helps improve production reliability.

* In case of marking to SUJ2 (material) by LP-S500W

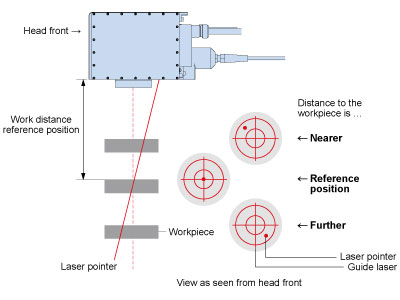

The LP-S500W series allows the operator to visualize the printable range based on the relationship between the positions of the guide laser and laser pointer. Now you can check target object position and height based on the laser pointer’s marker positions. Deviation amounts can also be checked. With this feature, equipment setup and maintenance gets a little easier.

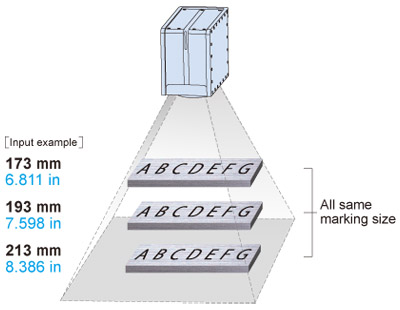

For accurate marking on workpieces with different heights, marking sizes, positions, etc. need modification in consideration of each target’s height. With the LP-S500W series, marking size and position are corrected automatically by entering the distances to each target object. Setting for marking target objects of different heights just got much simpler.

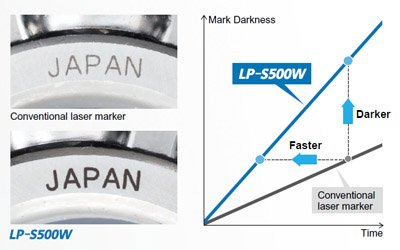

High-speed black marking

A significant amount of heat energy used to be needed to achieve a sufficiently dark black laser annealing. Featuring a high-output 42 W FAYb laser, the LP-S500W series has twice the output of other models*. Improve productivity with black laser annealing that is faster and that produces darker markings.

* LP-F13W

TOUGH

With a protective construction*1 that allowed the creation of the “IP67G Fanless Head”,a first*2 for the laser marking industry, the LP-S500W is strong enough to withstand the dirt, dust, water drops, oil mists and other elements common to harsh environments at manufacturing sites.

*1: Head section only

*2: Data obtained by Panasonic Industrial Devices SUNX as of February 2012

IP67G fanless head

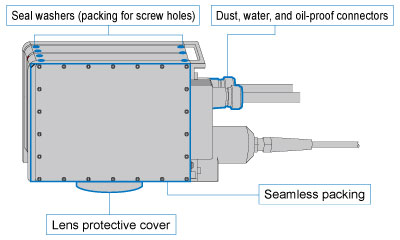

Use of high quality parts and well engineered design, have resulted in a robust IP67G enclosure.

The LP-S500W series features minimum frame seams. Minor seams and screw holes are completely sealed, producing high sealing performance. This performance is sustained by applying constant pressure to the sealed areas. Maximum cooling efficiency is also achieved allowing the use of a fanless head for thorough cooling.

High quality protection parts

Seamless sealing materials are used that have low water absorption and excellent oil resistance properties.

Connectors are dust, water, and oil-proof. The lens has a protective glass cover.

FLEXIBLE

A small head and the ability to remove and reinstall the fiber unit provides freedom in facility design

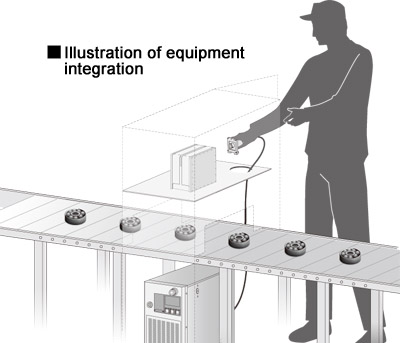

Meet the industry’s first*1 removable fiber unit, achieved through unique design.

Thanks to a small head and removable fiber unit, integration with other equipment just got simpler.

This allows for dramatic improvements in workability and equipment design freedom.

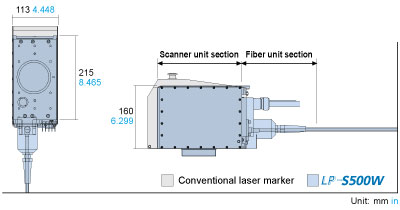

The LP-S500W series takes up close to 15 % less floor space with about 20 % less volume*1 compared to other models*2. Save floor costs by using more space-saving equipment.

*1: Scanner unit section

*2: LP-F series

Thanks to the removable fiber unit, a first*1 for the fiber laser marking industry, it is now easier than ever to maintain and integrate it with other equipment.

[Fiber Unit Removability Advantages]

- Smaller equipment, lower costs

- Simpler equipment assembly

- Simpler dismantling when transporting equipment

- Simpler laser marker maintenance

Universal Specs

With identical specs in Japan and overseas, you are always using the same machine.

Use the FAYb Laser Marker worry-free in any plant around the world.

Applications

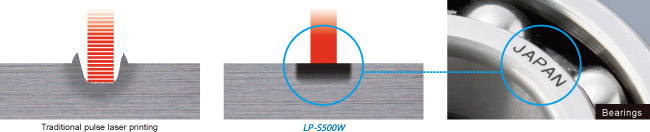

Bearings

End mills

Piston rings

What is black laser annealing?

Black laser annealing is a printing technique that uses laser irradiation to heat up metal surfaces and form oxide films that appear as letters printed in black*. In contrast to traditional techniques involving metal surface etching, the absence of depressions or burrs keeps surfaces level. This makes black laser annealing the best printing technique for target objects such as bearings that require high surface precision.

*Black laser annealing may not be possible with certain materials.

Specification

| Model No. | LP-S500W (Marking range 90 x 90 mm) | LP-S505W (Marking range 160 x 160 mm) | |

|---|---|---|---|

| Work distance reference position*1 | 193 mm 7.598 in | 357 mm 14.055 in | |

| Work distance range*2 | 173 to 213 mm 6.811 to 8.385 in | 327 to 387 mm 12.874 to 15.236 in | |

| Marking laser | Class 4 Yb fiber laser; wavelength: 1,070 nm 0.042 mil | ||

| Average output*3 | 42 W (?5 %) CW oscillation | ||

| Guide laser / pointer | Class 2 semiconductor laser; wavelength: 655 nm 0.026 mil | ||

| Marking range | 90 x 90 mm 3.543 x 3.543 in | 160 x 160 mm 6.299 x 6.299 in | |

| Scanning method | Galvano scanning method | ||

| Character settings(character height, width) | 0.1 to 90 mm 0.004 to 3.543 in (configurable in 0.001 mm 0.0004 in steps) | 0.1 to 160 mm 0.004 to 6.299 in (configurable in 0.001 mm 0.0004 in steps) | |

| Marking spacing (character spacing, line pitch) | 0 to 90 mm 0 to 3.543 in (configurable in 0.001 mm 0.0004 in steps) | 0 to 160 mm 0 to 6.299 in (configurable in 0.001 mm 0.0004 in steps) | |

| Arced output: -180? to +180? (configurable in 0.01? steps) | |||

| Marking shape | Straight Line, Arc, Propotional, Justify | ||

| Character types | English uppercase letters, English lowercase letters, numerals, katakana, hiragana, kanji (JIS No. 1 and No. 2 standards), symbols, user-registered characters (up to 50) | ||

| Barcodes | Code 39, Code 128, ITF, NW-7, JAN (EAN) /UPC, RSS-14 (GS1 DataBar), RSS (GS1 DataBar) Limited, RSS (GS1 DataBar) Expanded | ||

| 2D codes | QR Code, Micro QR Code, Data Matrix, GS1 Data Matrix | ||

| Composite codes | RSS-14 (GS1 DataBar) CC-A, RSS (GS1 DataBar) Stacked CC-A, RSS (GS1 DataBar) Limited CC-A, UCC / EAN COMPOSITE etc. | ||

| I/O | Input terminal, Output terminal, I/O connector | ||

| Interface | RS-232C, Ethernet | ||

| Cooling method | Head: Naturally air cooling, Controller: Forced air cooling | ||

| Power supply | 90 to 132 V AC, or 180 to 264 V AC (Auto-switching), 50 / 60 Hz | ||

| Power consumption | 470 VA or less (100 V AC), 650 VA or less (200 V AC) | ||

| Protection degree | Head: IP67G (Excluding the controller) | ||

| Ambient temperature | 0 to +40 ? +32 to +104 ? (Controller, Head) (No dew condensation or icing allowed) | ||

| Ambient temperature for storage | -10 to +60 ? +14 to +140 ? (Controller, Head) (No dew condensation or icing allowed) | ||

| Ambient humidity | 35 % to 85 % RH (Controller, Head) (No dew condensation or icing allowed) | ||

| Applicable standards | FDA regulations, CE marking*4 | ||

| Net weight | Head | 6.5 kg approx. | 7.0 kg approx. |

| Controller | 24 kg approx. | 24 kg approx. | |

- Work distance reference position represents the calculated center position of the work distance range. Depending on objects to be marked, optimal distance may vary.

- Work distance range represents the configurable work distance. Depending on objects to be marked, optimal distance or markable range may vary.

- This output is measured at the work end. (The preset power is 100, at the shipment time.)

- China models are available,too. Please contact our sales office.

Software for PC Setting of Laser Marker

| Software | Supported OS |

|---|---|

| Laser Marker Utility*1 | Microsoft Windows® 10 Pro (32 bit / 64 bit) / 8 Pro (32 bit / 64 bit) / 7 Professional (32 bit / 64 bit) / Vista Business (32 bit) / XP Professional (32 bit) |

*1 Windows® 10 Pro, 8 Pro, 7 Professional, Vista Business, and XP Professional are trademarks or registered trademarks of Microsoft Corporation in the United State and other countries

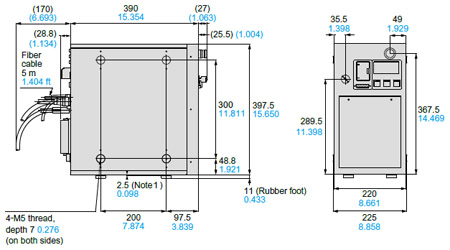

Controller

Note: 1) Indicates the height at the protruding section when the rubber foot are not attached. The rubber foot can be attached to either the right or left side of the controller.

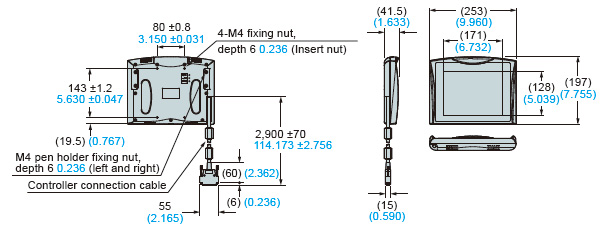

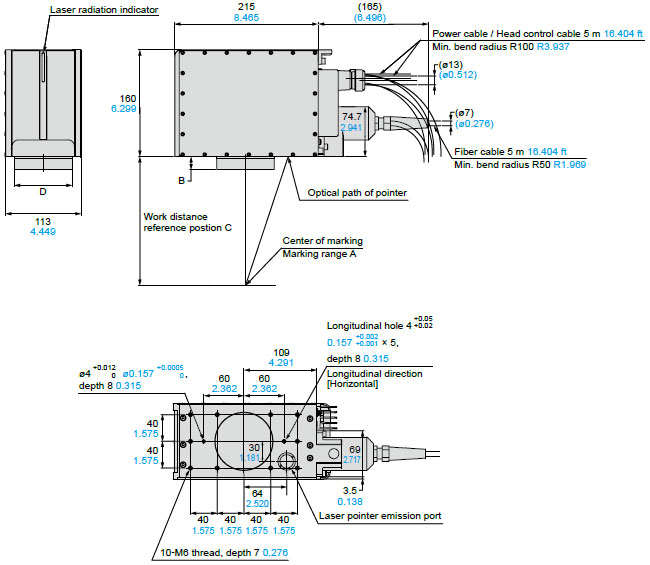

Head

Console