FAYb Laser Marker LP-V

CE , FDA Approved

CE : Low Voltage Directive, EMC Directive (Some models only)

FDA : Some models only

Features

High-speed marking at 700 cps

Contributes to productivity improvement

Laser Marker LP-V series, on which super high-speed marking is possible, greatly contributes to productivity improvement by shortening the takt time.

Enjoy dramatically reduced equipment costs since a single laser marker can now handle applications that previously required multiple units.

A great number of technologies drives high marking quality

The LP-V series take advantage of a number of new technologies to deliver even higher definition marking.

Every aspect of the product development process-from the superior beam produced by the FAYb system to control technologies designed to create more beautiful output-reflects a singleminded dedication to improving marking quality.

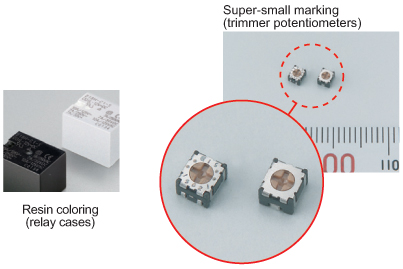

Marking capability that expands applications

The LP-V series has it all, delivering high peak power in a short-pulse laser with low thermal effects to enable beautiful. Various types of marking, from letters on metal and resin coloring, to infinitesimal letters, are possible.

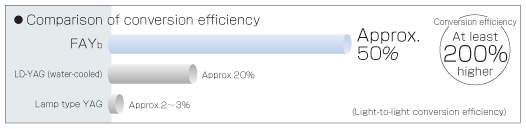

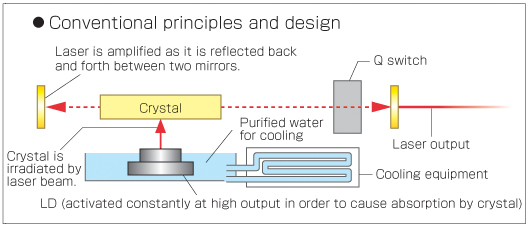

The FAYb system resolves the problems of conventional laser markers!

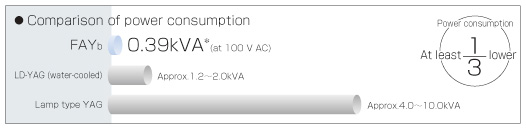

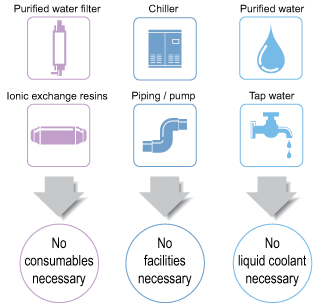

The FAYb system provides long life and high efficiency in a compact package that is completely air-cooled.

Equipment footprint, constraints on installation orientation, lamp replacement, adjustment of mirrors and other optical components, running costs, and other issues associated with conventional laser markers have all been addressed.

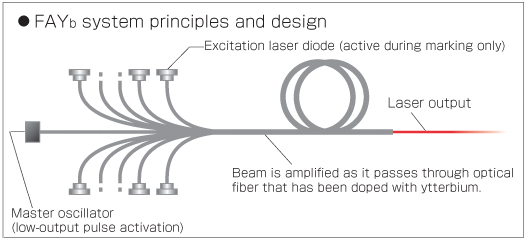

Innovative fiber system (FAYb)

Doping with the rare-earth element ytterbium, which has a beneficial effect on beam width, inside optical fiber allows the laser beam to be excited and amplified in an extremely efficient manner, yielding stable output.

Additionally, the use of a design where the excitation laser diodes are only activated during marking results in dramatically extended laser diode life.

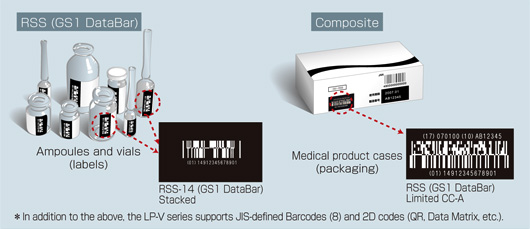

RSS (GS1 DataBar) code support

The LP-V series supports RSS (GS1 DataBar) and Composite codes, allowing product codes and other information to be output in a space-efficient manner on small medical products such as ampoules and vials.

Both normal and reversed (white on a black background) marking modes are supported.

Easily set by using a computer with the “Laser Marker NAVI” software

The LP-V series come standard with application software for easily configuring print data.

Marking layout can be easily performed as desired with intuitive and simple mouse operations. Moreover, batch control of multiple laser markers is possible using one computer. This significantly contributes to increased work efficiency.

Laser Marker NAVI included softwares

Extraordinarily easy to use color LCD equipped console LP-ADP40 (optional)

A color touch panel designed for maximum ease of use and viewing provides stress-free operation by displaying marking data and settings immediately.

The LP-V series laser markers can be operated using a commercially-available monitor and mouse instead of console as equipped with the VGA connector and mouse connector.

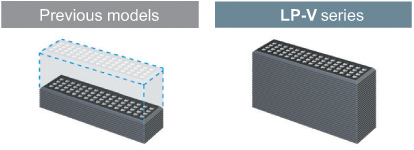

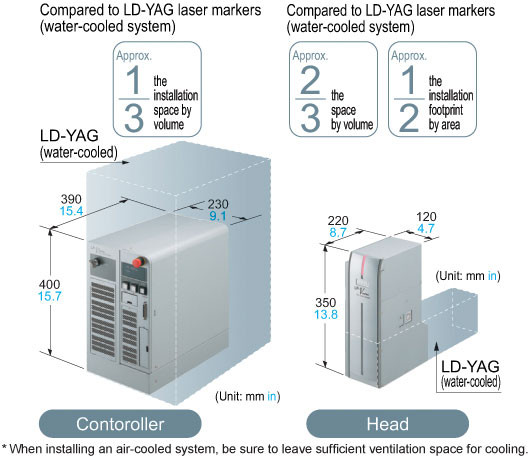

Space-saving design

The system’s head has a small footprint, and the ability to install it in any orientation ensures that no space will be wasted. Both LP-V series systems are surprisingly compact since they don’t require coolant pipes or additional cooling equipment. The result is reduced equipment and deployment costs.

No-alignment installation in any orientation

Because their oscillation method does not require the use of optical mirrors, FAYb laser markers are not susceptible to optical axis misalignment caused by vibrations or other mechanical disturbances. When moved, the system does not need to be re-aligned by a specialist engineer. Additionally, its completely air-cooled, space-saving design can be installed in any orientation as dictated by available space, target object characteristics, transport line type, and other factors.

Convenient features meet a variety of needs

- USB connectors

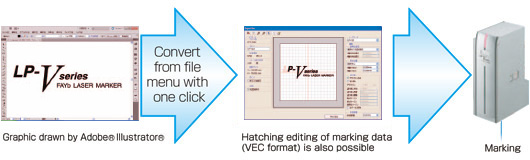

- Easy marking of Adobe® Illustrator® data

The ability to store system settings on standard USB memory sticks lets you backup marking settings or copy the same set of settings to multiple laser markers, delivering improved ease of use compared to the floppy disk drive used by previous models.

(The system also supports USB-connected floppy disk drives.)

* Customers are encouraged to verify proper operation of system components in advance when using off-the-shelf hardware.

Data created by Adobe® Illustrator® can be converted into marking data by “ExportVec”, which is a standard-included software. Logos or marks can be easily marked while staying true to the original Adobe® Illustrator® graphic images.

Bearing

Automotive illuminated buttons

Button cell (Stainless steel)

Tweezers (stainless steel)

Battery pack

Drill bits

Molded resin parts

Automotive parts

| Type | General-purpose type | Wide-area type | |

|---|---|---|---|

| Set model No. | LP-V10U | LP-V15U | |

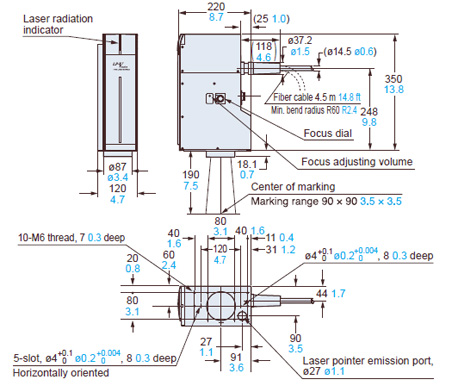

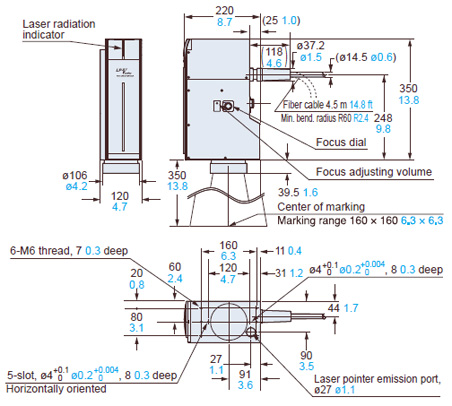

| Work distance (Note 1) | 190 mm 7.5 in | 350 mm 13.8 in | |

| Marking laser | Class 4 Yb fiber laser; wavelength: 1.06 ?m 0.042 mil | ||

| Average output (Note 2) |

12 W (pulse oscillation) | ||

| Guide laser/pointer | Class 2 semiconductor laser; wavelength: 655 nm 0.026 mil | ||

| Marking field | 90 x 90 mm 3.5 x 3.5 in | 160 x 160 mm 6.3 x 6.3 in | |

| Scan speed | Max. 12,000 mm/s | ||

| Line speed (Note 3) | 240 m/min or less | ||

| Installation orientation | All | ||

| Character settings (character height, width) | 0.2 to 90 mm 0.008 to 3.5 in (variable in 0.001 mm 0.00004 in steps) | 0.2 to 160 mm 0.008 to 6.3 in (variable in 0.001 mm 0.00004 in steps) | |

| Marking spacing (character spacing, line pitch) |

0 to 90 mm 0 to 3.5 in (variable in 0.001 mm 0.00004 in steps) Arced output: -180? to +180? (variable in 0.01?steps) |

0 to 160 mm 0 to 6.3 in (variable in 0.001 mm 0.00004 in steps) Arced output: -180? to +180? (variable in 0.01?steps) |

|

| Making shape | Straight Line, Arc, Proportional, Justify | ||

| Character types | English uppercase letters, English lowercase letters, numerals, katakana, hiragana, kanji (JIS No. 1 and No. 2 standards), symbols, user-registered characters (up to 50) | ||

| Barcodes | Code 39, Code 128, ITF, NW-7, JAN (EAN) / UPC, RSS-14 (GS1 DataBar), RSS (GS1 DataBar) Limited, RSS (GS1 DataBar) Expanded | ||

| 2D codes | QR Code, Micro QR Code, Data Matrix, GS1 Data Matrix | ||

| Composite codes | RSS-14 (GS1 DataBar) CC-A, RSS-14 (GS1 DataBar) Stacked CC-A, RSS (GS1 DataBar) Limited CC-A, etc. | ||

| Logos / Graphics | VEC (Note 4), BMP, DXF, HPGL, JPEG, AI (Note 5), EPS (Note 5) | ||

| Interface (Note 6) | RS-232C, Ethernet | ||

| Cooling method | Forced air cooling | ||

| Power supply | 90 to 132 V AC or 180 to 264 V AC (automatic switching),50/60 Hz | ||

| Power consumption | 390 VA or less (100 V AC); 420 V or less (200 V AC) | ||

| Inputs | Remote, trigger, encoder (A), encoder (B), shutter control, laser excitation, alarm reset, emergency stop, laser stop, etc. | ||

| Outputs | Power supply (+12 V), remote, marking ready, marking, marking complete, laser excitation, warning, alarm, configuration complete, counter complete | ||

| Marking condition | Static, On the fly | ||

| Functions | +Marking order optimization | ||

| +Intersection correction | |||

| +Counter marking | |||

| +Current date marking | |||

| +Deadline date marking | |||

| +Lot marking | |||

| +Logo data marking | |||

| +Font creation and editing | |||

| +Monospaced alignment | |||

| +Updating of operating screen display | |||

| +System offset | |||

| +Shared character settings | |||

| +Guide laser | |||

| +Dual pointers | |||

| +Overlapping marking | |||

| +Backup | |||

| +Marking on long moving objects | |||

| +Font selection | |||

| +Focus adjustment | |||

| +Proportional marking | |||

| +Marking image display | |||

| +Marking time measurement | |||

| +Target object image display | |||

| +Bold marking | |||

| +Rank marking | |||

| +Offset marking | |||

| +Time hold | |||

| +Step and repeat | |||

| +Operator adjustment | |||

| +I/O simulation | |||

| +Error log display | |||

| +Serial data marking | |||

| +Power check and correction | |||

| +I/O confirmation monitor | |||

| +Power and speed configuration by row or logo file | |||

| Emergency stop switch | Located on controller | ||

| Ambient temperature | 0 to +40 ? +32 to +104 ? (Storage: -10 to +60 ? +14 to 140 ?) (non-condensing and non-freezing) |

||

| Ambient humidity | 35 % to 85 % RH (non-condensing and non-freezing) | ||

| Net weight | Head | 9 kg | 10 kg |

| Controller | 22 kg | 22 kg | |

Notes:

1) Work distance varies by approx. ?2 mm ?0.079 in from model to model.

2) It is output of a laser oscillator.

3) Varies by target object.

4) VEC is a usable format of logo file for laser marker.

5) The PC installed Adobe Illustrator is necessary.

6) Ethernet has been changed from production in March 2013.

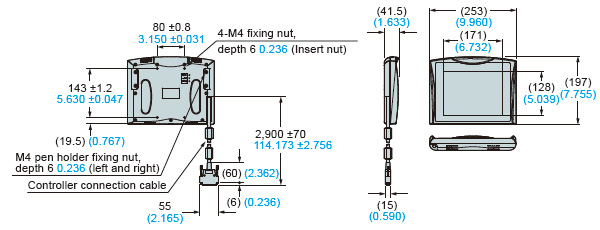

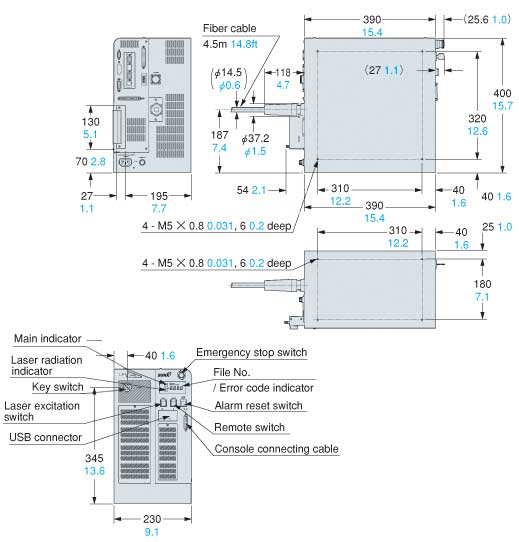

Controller

LP-V10U

LP-V15U

Console