Control-separated inverter VF66D

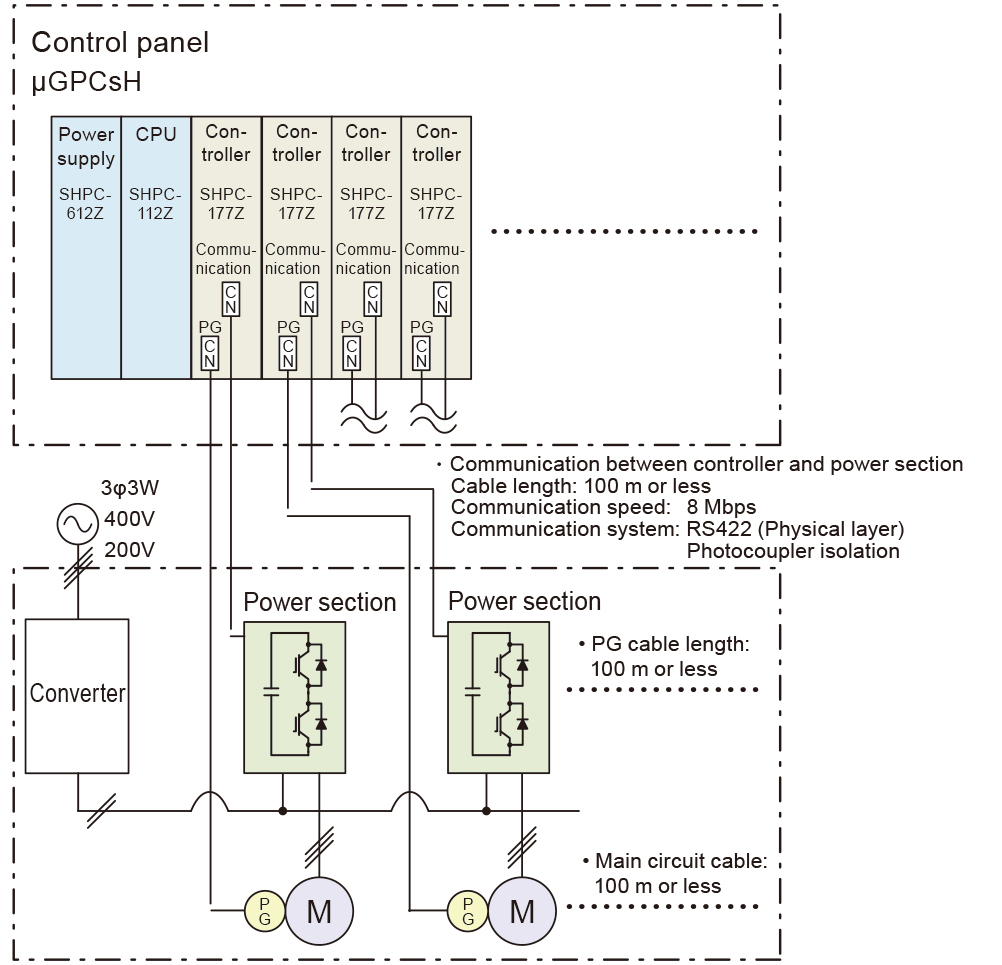

This control-separated inverter aims for a simplified control system by separating speed/position sensor input and various interfaces from the inverter and concentrating them in a control unit.

Features/functionality

- Simplified control system

- Separation between control and inverter: 100 m or less

This control-separated inverter concentrates input, such as speed information/sensors, and various interfaces on the PLC end. Control is performed by the PLC and the inverter is specialized for drive. Communication between the devices ties the whole system together.

The power section can be set up near the field, thereby reducing emission noise, and enabling a system of up to 150 units to be configured.

- Improved freedom of power section design

Isolating control from the power section made possible a wide variety of combinations, including those with a variety of supply voltages and power sections.

Control block diagram

Specifications

| Control method | 5 modes: EDM/IM vector control with sensor, EDM/IM vector control without sensor, and IM V/f control |

|---|---|

| Capacity | 200 V class: 2.2 to 180 kW 400 V class: 2.2 to 1,000 kW |

| Rated power | 200~220 V 380~460 V±10% 50/60 Hz±5% |

| Output frequency | 0.1~330 Hz |

| Overload capacity | 150% for 1 minute 200% for 3 seconds (when at low temperature, 75 kW or more is 150% max) |

| Speed control precision/range | Same as VF66B spec |

| I/O signal | Same as μGPCsH spec |

| Network | OPCN-1, PROFIBUS DP, DeviceNET, CC-Link, RS422/485, RS232C, Modbus RTU, CAN |

| Max number of units | 150 |