Advanced-function, high-capacity, water-cooled inverter/converter VF64(R)HPW

Features/functionality

- Unit configuration

- Built-in HC function and sequence function

- Support using PC tools

Each unit is 250 kW for up to 1,000 kW when four are connected in parallel. Performing current balance control between units connected in parallel eliminates the balance reactor, and a compact size has been enabled by the use of a high capacity IGBT and water-cooling.

Super block diagram and ladder screen

The HC function implements high-speed operations by combining approximately 30 super blocks that use a high-speed CPU for high-precision, high-response control of motor drive. The sequence function enables the building of approximately 100-step ladder programs within the inverter.

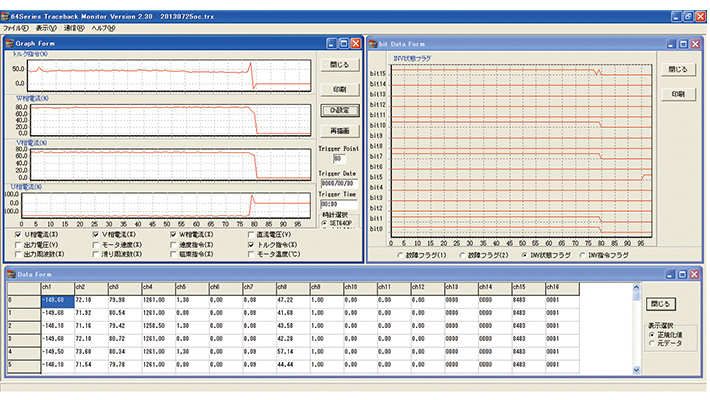

Monitoring of operation status and data collection are possible by utilizing the traceback/trend function, enabling precise engineering that quickly responds to system construction. Settings can be easily changed, exported, and copied using a PC.

Traceback screen

Specifications

| Control method | Vector control with a sensor, vector control without a sensor, and V/f control |

|---|---|

| Capacity | 400 V class: 750 kW, 1,000 kW, max current 1,840 A (at 1,000 kWh) |

| Rated power | 380~460 V±10% 50/60Hz±5% |

| Output frequency | 0~245 Hz |

| Overload capacity | 150% for 1 minute |

| Network | OPCN-1, PROFIBUS DP, DeviceNET, RS422/485, RS232C |

| Input signal | Analog 0 to 10 V/±10 V/4~20 mA (Standard 1CH, Optional max 2CH, External 2CH) 6 multifunction inputs |

| Output signal | Analog 0 to ±10 V (Standard 1CH, Optional max 2CH), PWM for 6x output frequency for rotation/frequency measurement 4 multifunction outputs |