Mitsuboshi Automotive Belts

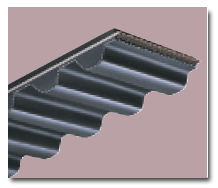

Positive Drive

S8M, MY, MR, XY, XR

MFTG (Round Tooth)

Timing belt for driving Over Head Camshaft in automative engine.

Installed inside engine compartment as an important functional component.

- Tension member is the secret of the belt’s strength and resistance to elongation.

- Heat, oil and abrasion resistance.

- Smooth engagement of belt with pulley allows high speed operation.

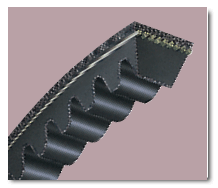

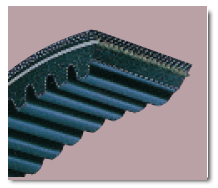

ZA, ZAS, ZB, ZBS

MFTG (Trapezoidal Tooth)

OHC drive timing belt that overcomes severe operating condition in engine compartment.

- High tensible strength gives remarkably small belt stretch.

- Heat, oil and abrasion resistance.

- Permits lightweight drive design with lower noise as compared to chain drives.

Frictional Drive

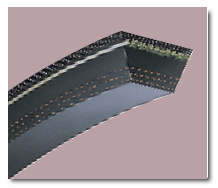

HM, MA, A, B, BC

REMF

Fabric free side face, flexible belt developed for automative applications.

- Mainly used for driving fans, alternators and airconditioners.

- Heat and oil resistant.

- Large gripping capacity resuces belt slip. High power transmission capacity belt.

HM, MA, A, B

MPMF

Laminated fabric construction provides smooth and noiseless drives.

- Larte gripping capacity reduces belt slip.

- Smaller stretch reduces belt noise.

- Abrasion, shock, bending and crack resistance extends belt service life.

- Also heat resistance.

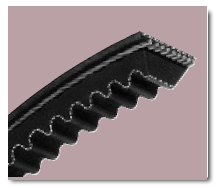

HM, MA, A, B, BC, C, CD

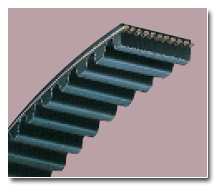

RAWEDGE COGGED V-BELT (RECMF)

Mainly used belt for heavy trucks and buses because of its longer service life.

- Excellent flexibility permits smaller pulley diameters and reduces energy consumption caused by bending.

- Performance remains unchanges even in high-speed operations.

- Heat and oil resistant provides longer service life.

- Smaller stretch offers maintenance free operation.

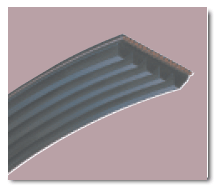

K

RIBSTAR G

V-ribbed belt that combines the high power transmission capacity of V-belt and the flexibility of flat belt. Specially designed to fulfill various functional requirements as automotive belt, such as lower energy consumption and longer service life.

- Have higher power transmission capacity.

- Flexibility allows multi-pulley drives.

- Allows high speed drives with smaller pulley diameters.

- Heat and abrastion resistance.

- Minimized belt stretch.

Top width: 10-100mm

RCVS

Variable speed belt for use in motorcycles, snowmobiles and golf carts.

- Excellent flexibility and side wall pressure resistance allow smaller pulley diameters.

- Excellent in heat, oil and abrastion resistance.

- Flexible characteristics provides longer service life.

A, B

WFC

Wider angle(52′) as compared with standard. Cogged profile allows improvement of bending fatigue resistance.