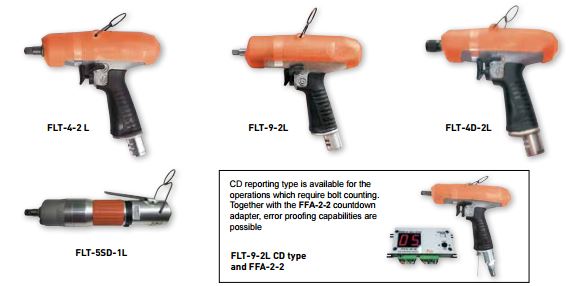

FLT series

SHUT-OFF VALVE MECHANISM

The Fuji shut-off valve and piston design provides the benefit of stable shut-off and torque levels. The design ensures smooth movement of the piston

which means oil pressure is transmitted precisely to the shut-off valve. In effect – both the accuracy and consistency of the tightening torque is improved

greatly. For the low air pressure operation 0.4-0.5 MPa (4-5 bar), low pressure models (-L) are provided with special design optimizing oil flow from relief

valve. Thanks to this design, even low oil pressure can be transmitted exactly to the shut-off valve.

Plunger Mechanism

Plunger Mechanism provides the benefit of improved Torque Accuracy.

For control of low torque, the oil pressure applied to the piston is maintained at a low level and improves torque control. To ensure high accuracy control

of low torque, the plunger mechanism is utilised to deliver troque accurately. Oil leakage is prevented within the mechanism via a passage in the plunger

which is designed to accommodate changes in oil pressure when the pulse is generated. Consequently, torque and tightening accuracy stability

are maintained.

Accumulator Mechanism

The Accumulator functions to compensate against the sudden rise of oil pressure when tightening a hard joint. Torque scatter and error is minimised.

As the oil temperature increases during consecutive tightening, the accumulator takes in the expanded volume of oil to maintain a consistent oil

volume in the pulse unit. This ensures high tightening torque accuracy

ENVIRONMENT FRIENDLY D

To reduce effects on the environment and environmental energy during the life cycle of the tool, no paint is applied to the body of the tool. Consequently,

the effect of paint peeling is eliminated. The full cover protector is designed as standard.

Ergonomic Design

Compared with conventionnal tools, weight is kept to a minimum. The grip handle size is optimised to

provide enhanced levels of operator comfort. This special grip also absorbs vibration more effectively.

Furthermor, reduced noise and vibration levels are standard with the FLT series due to the optimised

dimensions.

Standard Models (square drive – bit shank) Sq. 9.5 mm (3/8″) ~ 19 mm (3/4″) – Hex. 6.35 (1/4″)

Global specifications

| Model | Recommended Torque Range | Type | Free Speed | Square Drive Size / Bit Shank Size | Overall Length(without socket) | Weight(without socket) | Air Consumption(at Load) | Air Hose Size | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | ft.lb | min-1 | mm | in | mm | in | kg | lb | m3/min | ft3/min | mm | in | ||

| FLT-4SD | 5.5 – 11 | 4.1 – 8.1 | Straight | 5,500 | Hex 6.35 | Hex 1/4 | 221.5 | 8.72 | 0.88 | 1.94 | 0.35 | 12.4 | 6.3 | 1/4 |

| FLT-4D | 5 – 12 | 3.7 – 8.9 | Pistol | 6,200 | Hex 6.35 | Hex 1/4 | 181 | 7.13 | 0.97 | 2.14 | 0.4 | 14.1 | 6.3 | 1/4 |

| FLT-5SD | 11 – 20 | 8.1 – 14.8 | Straight | 6,400 | Hex 6.35 | Hex 1/4 | 221.5 | 8.72 | 0.88 | 1.94 | 0.36 | 12.7 | 6.3 | 1/4 |

| FLT-5D | 11 – 22 | 8.1 – 16.2 | Pistol | 6,500 | Hex 6.35 | Hex 1/4 | 181 | 7.13 | 0.97 | 2.14 | 0.45 | 15.9 | 6.3 | 1/4 |

| FLT-6SD | 21 – 30 | 15.5 – 22.1 | Straight | 5,800 | Hex 6.35 | Hex 1/4 | 234 | 9.21 | 0.95 | 2.1 | 0.42 | 14.8 | 9.5 | 3/8 |

| FLT-6D | 19 – 28 | 14.0 – 20.7 | Pistol | 6,300 | Hex 6.35 | Hex 1/4 | 193 | 7.6 | 1 | 2.21 | 0.55 | 19.4 | 9.5 | 3/8 |

| FLT-4S-1 | 5.5 – 11 | 4.1 – 8.1 | Straight | 4,300 | Sq 9.5 | Sq 3/8 | 222 | 8.74 | 0.88 | 1.94 | 0.33 | 11.7 | 6.3 | 1/4 |

| FLT-4-2 | 5 – 12 | 3.7 – 8.9 | Pistol | 6,200 | Sq 9.5 | Sq 3/8 | 180.5 | 7.11 | 0.97 | 2.14 | 0.4 | 14.1 | 6.3 | 1/4 |

| FLT-5S-1 | 11 – 20 | 8.1 – 14.8 | Straight | 6,400 | Sq 9.5 | Sq 3/8 | 222 | 8.74 | 0.88 | 1.94 | 0.36 | 12.7 | 6.3 | 1/4 |

| FLT-5-2 | 11 – 24 | 8.1 – 17.7 | Pistol | 6,500 | Sq 9.5 | Sq 3/8 | 180.5 | 7.11 | 0.97 | 2.14 | 0.45 | 15.9 | 6.3 | 1/4 |

| FLT-6S-1 | 21 – 30 | 15.5 – 22.1 | Straight | 5,800 | Sq 9.5 | Sq 3/8 | 234 | 9.21 | 0.95 | 2.1 | 0.42 | 14.8 | 9.5 | 3/8 |

| FLT-6-2 | 22 – 35 | 16.2 – 25.8 | Pistol | 6,300 | Sq 9.5 | Sq 3/8 | 192.5 | 7.58 | 1 | 2.21 | 0.55 | 19.4 | 9.5 | 3/8 |

| FLT-7-2 | 30 – 50 | 22.1 – 37.0 | Pistol | 6,100 | Sq 9.5 | Sq 3/8 | 189.5 | 7.46 | 1.1 | 2.43 | 0.6 | 21.2 | 9.5 | 3/8 |

| FLT-9-2 | 45 – 85 | 33.2 – 63.0 | Pistol | 5,300 | Sq 12.7 | Sq 1/2 | 209 | 8.23 | 1.6 | 3.53 | 0.68 | 24.0 | 9.5 | 3/8 |

| FLT-11-2 | 70 – 120 | 51.6 – 88.9 | Pistol | 5,000 | Sq 12.7 | Sq 1/2 | 217.5 | 8.56 | 1.85 | 4.08 | 0.8 | 28.2 | 9.5 | 3/8 |

| FLT-13-2 | 110 -150 | 81.1 – 111 | Pistol | 3,400 | Sq 12.7 | Sq 1/2 | 227.5 | 8.96 | 2.1 | 4.63 | 0.85 | 30.0 | 9.5 | 3/8 |

| FLT-20S-1 | 200 – 400 | 148 – 296 | Straight | 2,500 | Sq 19.0 | Sq 3/4 | 405 | 15.9 | 8.8 | 19.4 | 1.3 | 45.9 | 12.7 | 1/2 |

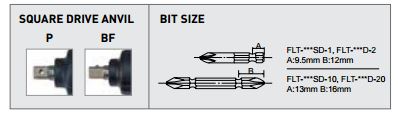

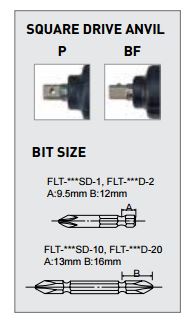

Tool selection guide

Standard models

| Model | Bolt Size | Normal type | CD reporting type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Square Drive Retainer | Driver Bit Size | Square Drive Retainer | Driver Bit Size | ||||||

| mm | P (Hole) | BF (Pin) | Short (-1) (-2) | Long (-10) (-20) | P (Hole) | BF (Pin) | Short (-1) (-2) | ||

| FLT-4SD-1 | M5 – M6 | 541 207 1809 | |||||||

| FLT-4SD-10 | M5 – M6 | 541 207 1810 | |||||||

| FLT-4D-2 | M5 – M6 | 541 210 3904 | 541 210 3906 | ||||||

| FLT-5SD-1 | M6 – M8 | 541 207 1834 | |||||||

| FLT-5SD-10 | M6 – M8 | 541 207 1835 | |||||||

| FLT-5D-2 | M6 – M8 | 541 210 3916 | 541 210 3918 | ||||||

| FLT-6SD-1 | M8 | 541 207 1860 | |||||||

| FLT-6SD-10 | M8 | 541 207 1861 | |||||||

| FLT-6D-2 | M8 | 541 210 3928 | 541 210 3930 | ||||||

| FLT-4S-1 | M5 – M6 | 541 206 0694 | 541 206 0695 | ||||||

| FLT-4-2 | M5 – M6 | 541 210 3898 | 541 210 3899 | 541 210 3901 | 541 210 3902 | ||||

| FLT-5S-1 | M6 – M8 | 541 206 0696 | 541 206 0697 | ||||||

| FLT-5-2 | M6 – M8 | 541 210 3910 | 541 210 3911 | 541 210 3913 | 541 210 3914 | ||||

| FLT-6S-1 | M8 | 541 206 0698 | 541 206 0699 | ||||||

| FLT-6-2 | M8 | 541 210 3922 | 541 210 3923 | 541 210 3925 | 541 210 3926 | ||||

| FLT-7-2 | M8 – M10 | 541 210 3934 | 541 210 3935 | 541 210 4262 | 541 210 3938 | ||||

| FLT-9-2 | M10 – M12 | 541 210 3940 | 541 210 3941 | 541 210 3943 | 541 210 3944 | ||||

| FLT-11-2 | M10 – M12 | 541 210 3946 | 541 210 3947 | 541 210 3949 | 541 210 3950 | ||||

| FLT-13-2 | M12 – M14 | 541 210 3952 | 541 210 3953 | 541 210 3955 | 541 210 3956 | ||||

| FLT-20S-1 | M16 – M20 | 541 205 3010 | |||||||

CE certified models

| Model | Bolt Size | Normal type | CD reporting type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Square Drive Retainer | Driver Bit Size | Square Drive Retainer | Driver Bit Size | ||||||

| mm | P (Hole) | BF (Pin) | Short (-1) (-2) | Long (-10) (-20) | P (Hole) | BF (Pin) | Short (-1) (-2) | Long (-10) (-20) | |

| FLT-4D-2 | M5 – M6 | 541 210 4011 | 541 210 4173 | ||||||

| FLT-5D-2 | M6 – M8 | 541 210 4018 | 541 210 4180 | ||||||

| FLT-6D-2 | M8 | 541 210 4024 | 541 210 4186 | ||||||

| FLT-4-2 | M5 – M6 | 541 210 4008 | 541 210 4172 | ||||||

| FLT-7-2 | M8 – M10 | 541 210 4027 | |||||||

| FLT-9-2 | M10 – M12 | 541 210 4030 | |||||||

| FLT-11-2 | M10 – M12 | 541 210 4034 | |||||||

| FLT-20S-1 | M16 – M20 | 541 207 1785 | |||||||

For CE region availability of non CE models, please inquire to your Fuji representative

NPT models

| Model | Bolt Size | Normal type | CD reporting type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Square Drive Retainer | Driver Bit Size | Square Drive Retainer | Driver Bit Size | ||||||

| mm | P (Hole) | BF (Pin) | Short (-1) (-2) | Long (-10) (-20) | P (Hole) | BF (Pin) | Short (-1) (-2) | Long (-10) (-20) | |

| FLT-4D-2 | M5 – M6 | 541 210 4012 | 541 210 4174 | ||||||

| FLT-4D-20 | M5 – M6 | 541 210 4014 | 541 210 4176 | ||||||

| FLT-5D-2 | M6 – M8 | 541 210 4019 | 541 210 4181 | ||||||

| FLT-5D-20 | M6 – M8 | 541 210 4020 | 541 210 4183 | ||||||

| FLT-6D-2 | M8 | 541 210 4025 | 541 210 4187 | ||||||

| FLT-6D-20 | M8 | 541 210 4026 | 541 210 4189 | ||||||

| FLT-5-2 | M6 – M8 | 541 210 4016 | |||||||

| FLT-6-2 | M8 | 541 210 4022 | |||||||

| FLT-7-2 | M8 – M10 | 541 210 4028 | |||||||

| FLT-11-2 | M10 – M12 | 541 210 4035 | |||||||

| FLT-13-2 | M12 – M14 | 541 210 4061 | |||||||

For possibility of NPT inlet for other models, please inquire to your Fuji representative.

For the low air pressure operation 0.4-0.5 MPa (4-5 bar), low pressure models (-L) are provided with special design optimizing

oil flow from relief valve. This design enables acurate and consistent tightening.

low pressure models

Global specifications

| Model | Recommended Torque Range | Type | Free Speed | Square Drive Size / Bit Shank Size | Socket Retainer | Overall Length(without socket) | Weight(without socket) | Air Consumption(at Load) | Air Hose Size | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | ft.lb | min-1 | mm | in | mm | in | kg | lb | m3/min | ft3/min | mm | in | |||

| FLT-4D | 4.5 – 8 | 3.3 – 5.9 | Pistol | 4,900 | Hex 6.35 | Hex 1/4 | Bit Shank (Hex) | 181 | 7.13 | 0.97 | 2.14 | 0.3 | 10.6 | 6.3 | 1/4 |

| FLT-5D | 8 – 16 | 5.9 – 11.8 | Pistol | 5,200 | Hex 6.35 | Hex 1/4 | Bit Shank (Hex) | 181 | 7.13 | 0.97 | 2.14 | 0.35 | 12.4 | 6.3 | 1/4 |

| FLT-5SD | 10 – 18 | 7.4 – 13.3 | Straight | 5,100 | Hex 6.35 | Hex 1/4 | Bit Shank (Hex) | 221.5 | 8.72 | 0.88 | 1.94 | 0.25 | 8.9 | 6.3 | 1/4 |

| FLT-6D | 14 – 22 | 10.3 – 16.2 | Pistol | 5,700 | Hex 6.35 | Hex 1/4 | Bit Shank (Hex) | 193 | 7.6 | 1 | 2.21 | 0.4 | 14.2 | 9.5 | 3/8 |

| FLT-6SD | 19 – 27 | 14.0 – 19.9 | Straight | 5,100 | Hex 6.35 | Hex 1/4 | Bit Shank (Hex) | 233.5 | 9.19 | 0.95 | 2.1 | 0.28 | 10.0 | 9.5 | 3/8 |

| FLT-4-2L | 4.5 – 10.0 | 3.3 – 7.4 | Pistol | 4,900 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 180.5 | 7.11 | 0.97 | 2.14 | 0.3 | 10.6 | 6.3 | 1/4 |

| FLT-5S-1L | 10 – 18 | 7.4 – 13.3 | Straight | 5,100 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 221.5 | 8.72 | 0.88 | 1.94 | 0.22 | 7.8 | 6.3 | 1/4 |

| FLT-5-2L | 10 – 18 | 7.4 – 13.3 | Pistol | 5,200 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 180.5 | 7.11 | 0.97 | 2.14 | 0.3 | 10.6 | 6.3 | 1/4 |

| FLT-6S-1L | 19 – 27 | 14.0 – 19.9 | Straight | 5,100 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 221.5 | 8.72 | 0.95 | 2.1 | 0.22 | 7.8 | 9.5 | 3/8 |

| FLT-6-2L | 12 – 26 | 8.9 – 19.2 | Pistol | 5,700 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 192.5 | 7.58 | 1 | 2.21 | 0.4 | 14.2 | 9.5 | 3/8 |

| FLT-7-2L | 24 – 45 | 17.7 – 33.2 | Pistol | 5,400 | Sq 9.5 | Sq 3/8 | Hole (P-Anvil) | 189.5 | 7.46 | 1.1 | 2.43 | 0.5 | 17.6 | 9.5 | 3/8 |

| FLT-9-2L | 45 – 75 | 33.2 – 55.3 | Pistol | 4,200 | Sq 12.7 | Sq 1/2 | Hole (P-Anvil) | 209 | 8.23 | 1.6 | 3.53 | 0.58 | 20.6 | 9.5 | 3/8 |

| FLT-11-2L | 65 – 110 | 47.9 – 81.1 | Pistol | 4,100 | Sq 12.7 | Sq 1/2 | Hole (P-Anvil) | 217.5 | 8.56 | 1.85 | 4.08 | 0.65 | 23.0 | 9.5 | 3/8 |

| FLT-13-2L | 80 – 125 | 59.0 – 92.2 | Pistol | 3,300 | Sq 12.7 | Sq 1/2 | Hole (P-Anvil) | 227.5 | 8.96 | 2.1 | 4.63 | 0.7 | 24.7 | 9.5 | 3/8 |

Tool selection guide

Standard models

| Model | Bolt Size | Normal type | CD reporting type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Square Drive Retainer | Driver Bit Size | Square Drive Retainer | Driver Bit Size | ||||||

| P (Hole) | BF | Short (-1) (-2) | Long (-10) (-20) | P (Hole) | BF | Short (-1) (-2) | Long (-10) (-20) | ||

| FLT-4D-20L | M5 – M6 | 541 210 4215 | |||||||

| FLT-4D-2L | M5 – M6 | 541 210 4213 | 541 210 4255 | ||||||

| FLT-5D-20L | M5 – M6 | 541 210 4222 | |||||||

| FLT-5D-2L | M5 – M6 | 541 210 4220 | 541 210 4258 | ||||||

| FLT-6D-20L | M6 – M8 | 541 210 4229 | |||||||

| FLT-6D-2L | M6 – M8 | 541 210 4227 | 541 210 4261 | ||||||

| FLT-4-2L | M5 – M6 | 541 210 4210 | 541 210 4211 | 541 210 4253 | 541 210 4254 | ||||

| FLT-5-2 | M6 – M8 | 541 210 4217 | 541 210 4218 | 541 210 3913 | 541 210 4257 | ||||

| FLT-6-2L | M6 – M8 | 541 210 4224 | 541 210 4225 | 541 210 4259 | 541 210 4260 | ||||

| FLT-7-2L | M8 – M10 | 541 210 4231 | 541 210 4232 | 541 210 4262 | 541 210 4263 | ||||

| FLT-9-2L | M10 – M12 | 541 210 4234 | 541 210 4235 | 541 210 4264 | 541 210 4265 | ||||

| FLT-11-2L | M10 – M12 | 541 210 4237 | 541 210 4238 | 541 210 4266 | 541 210 4267 | ||||

| FLT-13-2L | M12 – M14 | 541 210 4240 | 541 210 4241 | 541 210 4268 | 541 210 4269 | ||||

CE region availability of non CE models, please inquire to your Fuji representative. For possibility of NPT inlet for other models, please inquire to your Fuji representative.