Mitsuboshi Industrial Belts

Positive Drive

S8M, S14M

SUPER TORQUE G

Timing belt with round shape tooth profile which provides high power transmission. Expands timing belt application fields. Replaces conventional chain and gear drives.

- Wider application ranges with higher power transmission capacity.

- Longer service life.

- Lower noise level.

- Cost saving.

S1.5M, S2M, S3M, S5M

SUPER TORQUE GN

Small tooth pitch belt with advantages of Super Torque G. Suitable for smoother drive applications.

- Flexible belt permits smaller pulley diameters.

- Noiseless and longer service life by smooth engagement between pulley and belt.

- Higher torque transmission by small size belt.

- Assures higher positioning accuracy.

H8M, H14M

“H” SERIES

Round-shape belt tooth enables the distribution of the load stress uniformly over the entire belt tooth.

Since the belt tooth engages with the pulley groove without any interference, stress concentration at the root of the belt tooth can be climinates.

MXL, XXL, XL, L, H, XH, XXH

TIMING BELT G

Suitable for synchronous drives.

Removes disadvantages of chain and gear drives.

- High power transmission capacity with higher transmission efficiency.

- Lower noise generation as compared with chain or gear drives.

- No maintenance required.

- Lightweight, thin and flexible characteristics allow space saving drive design.

- The ambient temperatu range for operation of the standard belt is -30 to +90oC.

Static conductive.

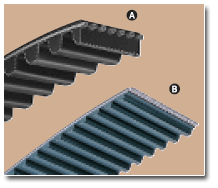

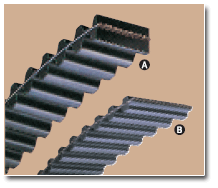

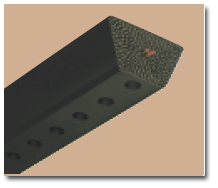

(A) Mega torque G MTS5M, MTS8M, MTS14M

(B) Mega torque U MTS8M

MEGATORQUE G & U

The power rating is about 2 times as high as rubber timing belt (Same profile pitch), when using the same pulley.

- Compact design.

- High power transmission.

- Lower Noise.

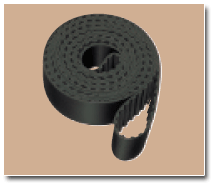

S2M, S3M, S5M, S8M, S14M

MXL, XL, L, H

LONGSIZE, OPEN END BELT

Suitable for long center-distance, synchronous, back and forth drives.

- Permits larger degree of freedom in belt drive design.

- Suitable for slipless, synchronous materials handling applications.

- Suitable for long center-distance, light duty synchronous drives.

S8M, S14M

L, H, XH, XXH

LONGSIZE, ENDLESS BELT

Recommended for long center distance drives.

- Suitable for slipless, synchronous material handling applications.

- Suitable for long center-distance, light duty synchronous drives.

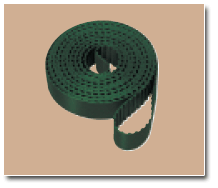

T5, T10, XL, L, H, S5M, S8M

AT5, AT10

FREE-SPAN, OPEN END BELT

Thermoplastic polyurethane belt suitable for long center-distance, synchronous back and forth drives.

- Long belts (up to 100m) are available.

- Felt or polyurethane attachments can be made on back face of belt.

- Lubrication-free, clean drives.

DT5, DT10

DOUBLE SIDED TG (Polyurethane)

Polyurethane belt with teeth on both fases. Recommended for positive, multi-pulley drives.

- Suitable for slipless, positive multi-pulley drives.

- Since special tooth profiles with different tooth pitches can be molded on back face, a wide variety of multi-pulley drives can be designed.

- Lighter than chains and gears. Suitable for high speed drives. Suitable for high speed drives. Space saving.

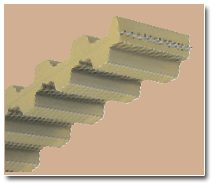

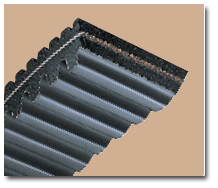

(A) DS3M, DS5M, DS8M, DS14M (Round tooth profile)

(B) DMXL, DXL, DL, DH (Trapezoid tooth profile)

DOUBLE SIDED TG (Rubber)

Provided with symmetrical teeth on both sides, this belt is suitable for positive, multi-pulley drives.

- Recommended for slipless, positive multi-pulley drives.

- Lighter than chains and gears. Suitable for high speed drives. Space saving.

- Maintenance free.

Frictional Drive

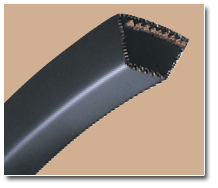

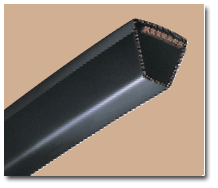

(K) M, A, B, C, D, E

STANDARD V-belt/RED V-belt

Most widely used power transmission belt. Economical and easily obtained for replacements.

- “SET FREE” provides assured belt length matching and easy inventory control.

- High power capacity Red V-belts are heat & oil resistance, plus static conductive.

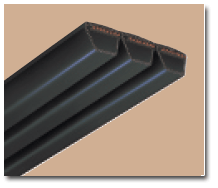

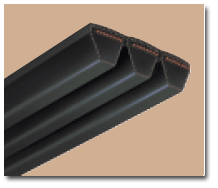

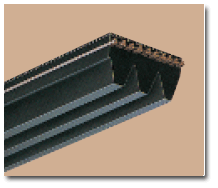

RA, RB, RC, RD, RE

MULTI V

Multiple strands of standard/Red V-belts are inseperably joined, providing transverse rigidity.

- Suitable for compressors, crushers and other tough machines where belt whip, turn-over is caused by pulsating shock load.

- Useful for material handling applications by using back faces of the belts.

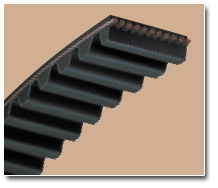

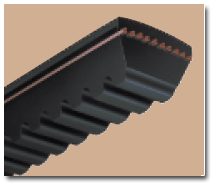

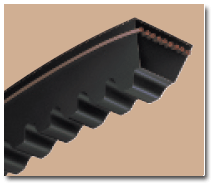

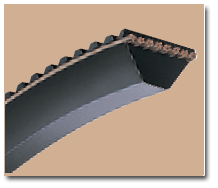

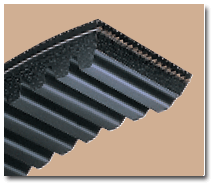

AX, BX, CX

VX

Rawedge cogged V-belt designed for industrial use.

- High capacity power transmission with space saving.

- Cogged profile yields greater belt flexibility and allows smaller pulley diameters.

- Suitable for heavy duty, high speed drives.

- High power transmission efficiency saves energy.

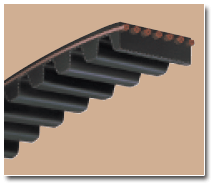

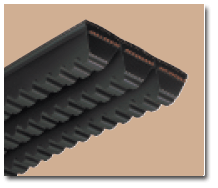

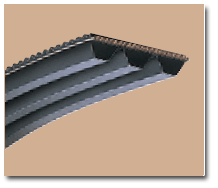

RAX, RBX, RCX

MULTI VX

Consists of VX type V-belts joined with tie band.

- Offers stable, vibration-free drives under pulsating shock loads.

- Cogged construction assures use of smaller pulley diameters than conventional V-belt drives.

- Suitable for vertical shaft drives such as mixers, agitators without belt jumping off the pulley.

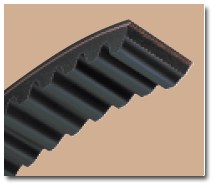

Maxstar Wedge : 3V, 5V, 8V

Narrow V : SPZ, SPA, SPB, SPC

MAXSTAR WEDGE, NARROW V

Offers high power transmission capacity with specially designed narrow topwidth profile.

- Permits space saving drive designs and lower energy consumption.

- High speed drives up to 40 m/sec.

- Designed as “SET FREE” to allow multi-strand drives.

- Wedge pulleys with bushings offer easy installation.

R3V, R5V, R8V

MULTI-MAXSTAR WEDGE

Consists of MAXSTAR WEDGE V-belts joined with tie band.

- Does not tun over or run off the pulley even under heavily pulsating load conditions.

- Offers stable driving even in long center distance drive application.

- Applicable to vertical shaft drives with out belt running off the pulley.

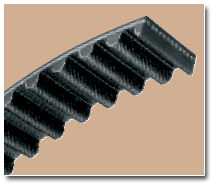

Maxstar Wedge Supreme : 3VX, 5VX

Narrow Rawedge cogged V : SPZX, SPAX, SPBX, SPCX

MAXSTAR WEDGE SUPREME NARROW RAW EDGE COGGED V BELT

Rawedge cogged MAXSTAR WEDGE V-belt.

- Combines advantages of both wedge belt and rawedge cogged belt. High power transmission capacity belt.

- Permits economical and space saving drive design.

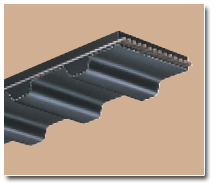

R3VX, R5VX

MULTI-MAXSTAR WEDGE SUPREME

Consists of MAXSTAR WEDGE SUPREME V-belts joined with tie band.

- High power transmission belt that resovles the problems such as belt turning-over and belt running-off the pulley raised by multi-strand belt drives.

- Offers stable operation even under pulsating high shock load condition.

J, K, L

RIBSTAR G

Combines high power transmission capacity of V-belt and flexibility of flat belt.

- Suitable for high speed, high efficiency drives.

- Flexibility allows smaller pulley diameters.

- Heat and wear resistant.

- Minimizes belt vibration and provides space saving drive design.

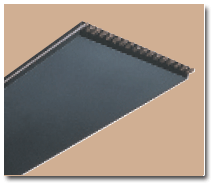

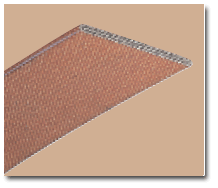

FL, FM, FH, FLEG, FLG, FLE, FMG, FHG

FLEXSTAR

Its high power transmission capacity allows space saving drive design and reduces maintenance cost.

- High speed drive up to 60 m/sec. is possible with lower vibration and noiseless running.

- Heat and oil resistant. Also static conductive.

- Smaller belt stretch reduces belt retensioning intervals. Also allows low-cost belt drives.

FU, FW, FY

SUPER FLEXSTAR

Suitable for compress. Three types are available. FU for low pressure, FW for high pressure, FY for oil resistance.

- Abrasion resistance, high strength.

- Use for conveyer application except compressed.

F20, F20D

FREE-SPAN FLAT BELT

This flat belt is applicable to conveying of light weight products and lifting up and down of elevating machine. Steel wire cords provide low stretch and few variation of length corresponding to change in temperature and humidity.

3M, 5M, 7M, 11M

POLYMAX

60o angle series wide angle belt.

- Suitable for high speed, smooth drives with minimum vibration.

- Allows space saving drive design.

- Smaller belt stretch and shrinkage offer maintenance-free operation.

- Long service life with weather resistance.

R5M, R7M, R11M

MULTI POLYMAX

Back faces of POLYMAX V-belts are joined with poly-amide fabric and polyurethane.

- Stable running.

- High-speed drives with reduced vibration.

- Smaller stretch offers maintenance-free operation.

M, A, B, C

Perforated V-belt

Open-ended V-belting with joint holes can be abjusted to required length simply with splicing bracket.

- Recommended for temporary use when the existing V-belt has to be replaced urgently.

- Permits easy belt replacement without requiring machine disassembly.

- Belt length for multi-strand drive can be adjusted easily.

- Can be used for material handing purposes with multi-strand drive.

- Suitable for trial running of machines.

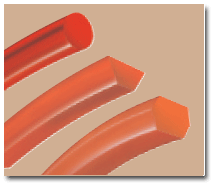

STAR ROPE / Prene V / Prene HEXAGON / SUPER STAR ROPE

Open-end polyurethane belting.

- Suitable for complicated drives such as multi-pulley drives, multi-directional drives, etc.

- Easily joined by hot melt method. Required belt length can be easily obtained.

- Abrasion, oil and weather resistant.

Top width 10~120mm

RCVS

Specially designed for variable speed applications.

- Flexible and side pressure resistant.

- Heat, oil, chemical and abrasion resistant.

- Longer service life with higher flexibility.

SUPER VS

High efficiency, precision, long-life belt designed for variable speed applications.

- Smaller stretch and high flexibility characteristics allow space saving belt drive design.

- Permits accurate and smooth speed change.

- Oil, heat and side wall pressure resistant.

Top width 20~120mm

DCVS

Belt designed for high-horsepower applications or compact drives.

- High power transmission capacity with higher side wall pressure resistance.

- Oil, heat and abrasion resistant.

P, H, SP

SPECIAL PORT/PORT/HARBOR

Strong belt consisting of best quality cotton fabric.

- Resistant to frequent bendings with minimum stretch and shrinkage.

- Heat, water and oil resistant.