Features

EMERGENCY PULL-WIRE SWITCH KP-850/860/870 CONVEYOR-BELT ALARM SWITCH KP-880

The secure operations ensure the safety of conveyor lines!

[KP-850/860/870]

- The simple structure makes the operation secure!

- A two-way operation method is used.

- The protection code is IP-67.

- The maximum length of the pull-wire rope is 50 m.

[KP-880]

- The simple structure makes the operation secure.

- The protection code is IP-67.

- As the switch has 2 contacts, it can be used for alarm and control simultaneously.

Operation Principles

In the case of emergency stop of a conveyor, the cam is surely operated by the ratchet mechanism and spring provided for the shaft to make the contact operate, when the wire is pulled from an arbitrary position. The contact operation is maintained until the recovery lever is operated.

Standard Specification

| Specification/Model | KP-850-1 | KP-860 | KP-870 | KP-880 |

|---|---|---|---|---|

| Action | Manual-reset | Manual-reset | Manual-reset | Auto Recovery |

| Indication | Indication Lamp(Red) | Indication Plate(Red) | ||

| Power Source | No | 100, 200VAC or 24VDC | No | No |

| Output Contact | SPDT x 1(Optionally available is SPDTx2) | SPDT x 2 | SPDT x 2 | SPDT x 2 |

| Contact Capacity | AC250V 10A | AC250V 10A | AC250V 10A | AC250V 10A |

| Process Connection | 2-φ10Pich 110 | 2-φ10Pich 110 | 2-φ10Pich 110 | 2-φ10Pich 110 |

| Enclosure Rating | IP-67 | IP-67 | IP-67 | IP-67 |

Product Lineup

KP-850

KP-860

KP-870

KP-880

Features

FLOW SWITCH KP-4/810/820/830,KPG-840

Most suitable for detecting a flow on a conveyor!

[KP-4]

- Intended for installation on the wall surface

- Only urethane rubber is used as the material of the sensing plate.

[KP-810]

- Most suitable for detecting a flow on places where robustness is required such as coal, crushed stone, mineral ore, and so on.

- As the shaft is protected by a spring, the meter has a structure resistant to overloads. [KP-820]

- As torque can be adjusted freely, the meter can be used for a low specific gravity.

- Materials (SUS, rubber) and size of the sensing plate can be selected freely.

[KP-830]

- Most suitable for detecting a falling substance in a tilt chute.

- The L dimension can be selected freely.

[KPG-840]

- It has a pressure-proof and explosion-proof structure and can be used in places where combustible dust such as coal is produced and dangerous places where a combustible gas is present.

- A magnet coupling method is used for the switch and the sensing unit. The seal bellows prevent malfunctions due to dust adhesion.

Operation Principles

A measured substance carried by a conveyor pushes the sensing plate of the flow switch, and the internal cam mechanism activates the micro switch to make contact output.

When the measured substance passes over, the restraint of the sensing plate is released and the sensing plate goes back into position by its own weight and spring force. Then, the contact output is released.

Standard Specification

| Specification/Model | KP-4 | KP-810 | KP-820 | KPG-840 |

|---|---|---|---|---|

| Power Source | No need | No need | No need | No need |

| Output Contact | SPDT x 1 | SPDT x 2 | SPDT x 1 | SPDT x 1 |

| Contact Capacity | AC250V 10ADC30V 10A | AC250V 10ADC30V 10A | AC250V 5ADC30V 5A | AC250V 5ADC30V 5A |

| Contact Operating Angle | About 5° | About 10°,15° | About 15° | About 15° |

| Process Connection | 4 ×φ7 hole | 4×φ12 hole | 6×φ7 hole | JIS 5K 65A |

| Enclosure Rating | Equivalent to IP-43 | Equivalent to IP-X3 | Equivalent to IP-43 | IP-67 |

Product Lineup

KP-4

KP-810

KP-820

KP-830

KPG-840

Features

SPEED DETECTOR KPS Series

Surely detects the speed change of the conveyor!

Prevents parts and motors from being damaged.

- High precision detection is achieved by using a digital control method.

- The operating speed can be set freely with the range of 3 to 1999 rpm.

- The built-in startup compensation timer makes it possible to set up the startup compensation of 99 seconds at the maximum.

- Use of a proximity sensor for the sensing unit makes the detector contact-free and eliminate moving parts, which results in the long life duration.

(KPS-21) - As the conveyor belt speed is detected directly, the speed change of the belt alone is surely detected.

Operation Principles

An electrical signal is sent from the built-in photo sensor through the rotation of the cam installed on the shaft or from the built-in proximity sensor through the rotation of the metal piece installed on the mechanical unit.

By counting this electrical signal for a given length of time, the shaft rotation speed is detected as the rotation speed per minute. The contact output is executed when the rotation speed reaches below the preset speed.

Standard Specification

| Power Source | 105/210VAC ±10% 50/60Hz |

|---|---|

| Power Consumption | 2.5VA |

| Output Contact | SPDT x 1 |

| Contact Capacity | 250VAC 5A, 30VDC 5A |

| Permissible Speed | below 2000rpm |

| Setting Range | 3~1999rpm |

| Measurement Error | 2rpm |

| Start-up Compensation Timer | 0~99seconds |

| Temperature | -10℃~+60℃ |

| Enclosure Rating | Equivalent to IP-54 |

Product Lineup

KPS-11

KPS-21

KPS-123/124

Features

LEAK TYPE LEVEL SWITCH KEL-2

There is no moving part.

Most suitable for detecting sand, aggregate, lime, and so on.

- It can be used for almost all substances including construction aggregates, gravels, and crushed stones, as long as they contain moisture to some extent.

- The sensitivity can be set easily.

- It is very easy to install and handle the meter. No deep knowledge and technique are needed.

- As the current that flows measured substances is several dozen μA, heat and sparks are not produced from the electrode, which ensures the safe operation.

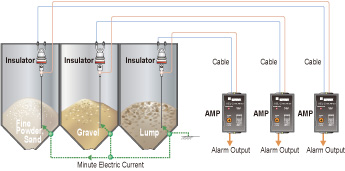

Operation Principles

A measured substance that contains moisture to some extent is constantly made contact with the electrode. When the resistance between the electrode and the metal tank wall is reduced, the change of the resistance is detected and the output contact is switched.

When the measured substance passes over, the output contact is restored to the initial state.

Standard Specification

| Power Source | 105/210VAC ±10% 50/60Hz |

|---|---|

| Output Contact | SPDT x 1 |

| Contact Capacity | 250VAC 10A |

| Temperature | 0~+50℃(No Condensation or Freez required) |

| Detecting Sensitivity | Max.about 10MΩ – Min.about 30kΩ |

| Sensitivity Setting | 16 Steps adjustable between Max. & Min. |

Product Lineup

KEL-2

Features

TILT TYPE SWITCH TC Series

The tilt type level switch has only one moving part!

Levels are detected by simple and sure operations!

- It has a simple structure and can withstand severe impact loads of particulates.

- It can be used for upper, middle, and lower limits.

- No power source is needed and wiring cost is low.

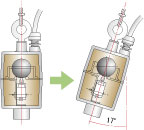

Operation Principles

When the main body hung from the top of the tank is tilted by the repose angle of the measured substance, the tilt of the main body is detected and the contact is switched.

When the measured substance passes over, the output contact is restored to the initial state.

Standard Specification

| Specification/Model | TC-3 | TC-1 |

|---|---|---|

| Weight | About 1.3Kg (Aluminum casting) | About 11Kg (Cast-iron) |

| Output Contact | SPDT x 1 | SPDT x 1 |

| Contact Capacity | 250VAC 10A | 250VAC 10A |

| Temperature | -10~+80℃(No condensation / no freezing) | -10~+120℃(No condensation / no freezing) |

| Conduit Connection | 3/8″ (with gland) | 1/2″ (with gland) |

| Conformable Cable | 3/8 inch three-core cable | 1/4 inch two-core cable |

| Sensing-paddle fitting | NPT 1/2 | NPT 1 |

| Enclosure Rating | IP-56 | IP-56 |

Product Lineup

TC-3

TC-1