Miki Pulley AL Models

Specifications

| Model | Torque | Misalignment | Max. rotation speed [min-1] | Moment of inertia [kg・m2] | Mass [kg] | |||

|---|---|---|---|---|---|---|---|---|

| Nominal [N・m] | Max. [N・m] | Parallel [mm] | Angular [°] | Axial [mm] | ||||

| AL-035 | 0.5 | 1.5 | 0.1 | 0.5 | +0.3 | 18000 | 0.38×10-6 | 0.01 |

| AL-050 | 1.5 | 4.5 | 0.2 | 1.0 | ±0.5 | 12000 | 5.10×10-6 | 0.06 |

| AL-070 | 3 | 9 | 0.2 | 1.0 | ±0.5 | 9000 | 1.79×10-5 | 0.12 |

| AL-075 | 5 | 15 | 0.2 | 1.0 | ±0.5 | 7000 | 5.36×10-5 | 0.21 |

| AL-090 | 8 | 24 | 0.3 | 1.0 | ±0.5 | 6000 | 1.15×10-4 | 0.31 |

| AL-095 | 10 | 30 | 0.3 | 1.0 | ±0.5 | 6000 | 1.40×10-4 | 0.36 |

| AL-100 | 25 | 75 | 0.3 | 1.0 | ±0.7 | 5000 | 4.34×10-4 | 0.78 |

| AL-110 | 50 | 150 | 0.3 | 1.0 | ±0.7 | 4000 | 1.43×10-3 | 1.56 |

*Max. rotation speed does not take into account dynamic balance or mounting misalignment.

*The moment of inertia and mass are measured for the pilot bore.

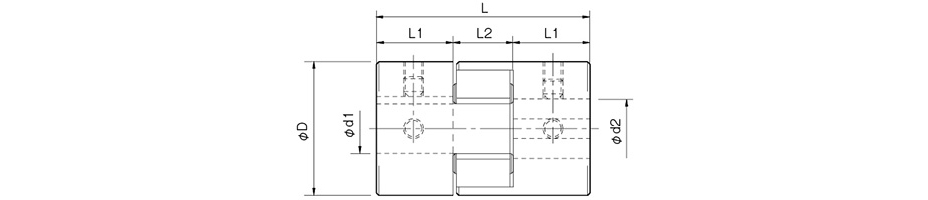

Dimensions

Unit [mm]

| Model | d1, d2 | D | L | L1 | L2 | ||

|---|---|---|---|---|---|---|---|

| Pilot bore | Min. | Max. | |||||

| AL-035 | 4 | 4 | 8 | 16.1 | 20.5 | 6.5 | 7.5*1 |

| AL-050 | 5 | 6 | 16 | 27 | 43.2 | 15.5 | 12.2 |

| AL-070 | 5 | 6 | 20 | 35 | 49.2 | 18.5 | 12.2 |

| AL-075 | 5 | 7 | 26 | 45 | 54.4 | 21.0 | 12.4 |

| AL-090 | 5 | 9 | 28 | 54 | 55.0 | 21.0 | 13.0 |

| AL-095 | 5 | 9 | 28 | 55 | 61.0 | 24.0 | 13.0 |

| AL-100 | 5 | 11 | 36 | 66 | 88.0 | 35.0 | 18.0 |

| AL-110 | 5 | 11 | 48 | 85 | 110.0 | 44.0 | 22.0 |

*”Pilot bore” refers to center processing. Minimums and maximums for d1 and d2 are values at the MIKI PULLEY standard hole-drilling standards.

*The value marked *1 leaves a 1 mm space for the thickness of the spider body.

Dimensions

Unit [mm]

| Coupling Model | Spider Model | L2 | R | K |

|---|---|---|---|---|

| AL-035 | L-035 | 6.5 | ― | ― |

| AL-050 | L-050 | 12.2 | ― | ― |

| AL-070 | L-070 | 12.2 | ― | ― |

| AL-075 | L-075 | 12.4 | 20 | 6.0 |

| AL-090 | L-090/095 | 13.0 | 22 | 6.3 |

| AL-095 | L-090/095 | 13.0 | 22 | 6.3 |

| AL-100 | L-100 | 18.0 | 26 | 6.0 |

| AL-110 | L-110 | 22.0 | 30 | 6.0 |

Standard Hole-drilling Standards

Unit [mm]

| Models compliant with the old JIS standards (Class 2) | Models compliant with the new JIS standards | Models compliant with the new motor standards | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal bore diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal bore diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) |

| Tolerance | H7, H8 | E9 | +0.30 | – | Tolerance | H7 | H9 | +0.30 | – | Tolerance | G7, F7 | H9 | +0.30 | – |

| 6 | 6+0.0180 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 7 | 7+0.0220 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 8 | 8+0.0220 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 9 | 9+0.0220 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 10 | 10+0.0220 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 11 | 11+0.0180 | – | – | 2-M4 | – | – | – | – | – | – | – | – | – | – |

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8 | 2-M4 | – | – | – | – | – |

| 14 | 14+0.0180 | 5+0.050+0.020 | 16.0 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3 | 2-M4 |

| 15 | 15+0.0180 | 5+0.050+0.020 | 17.0 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3 | 2-M4 | – | – | – | – | – |

| 16 | 16+0.0180 | 5+0.050+0.020 | 18.0 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3 | 2-M4 | – | – | – | – | – |

| 17 | 17+0.0180 | 5+0.050+0.020 | 19.0 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3 | 2-M4 | – | – | – | – | – |

| 18 | 18+0.0180 | 5+0.050+0.020 | 20.0 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8 | 2-M5 | – | – | – | – | – |

| 19 | 19+0.0210 | 5+0.050+0.020 | 21.0 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8 | 2-M5 |

| 20 | 20+0.0210 | 5+0.050+0.020 | 22.0 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8 | 2-M5 | – | – | – | – | – |

| 22 | 22+0.0210 | 7+0.061+0.025 | 25.0 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8 | 2-M5 | – | – | – | – | – |

| 24 | 24+0.0210 | 7+0.061+0.025 | 27.0 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3 | 2-M6 |

| 25 | 25+0.0210 | 7+0.061+0.025 | 28.0 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3 | 2-M6 | – | – | – | – | – |

| 28 | 28+0.0210 | 7+0.061+0.025 | 31.0 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3 | 2-M6 |

| 30 | 30+0.0210 | 7+0.061+0.025 | 33.0 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3 | 2-M6 | – | – | – | – | – |

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3 | 2-M8 | – | – | – | – | – |

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3 | 2-M8 | – | – | – | – | – |

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3 | 2-M8 |

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3 | 2-M8 | – | – | – | – | – |

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3 | 2-M8 |

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8 | 2-M10 | – | – | – | – | – |

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8 | 2-M10 |

*The ø11 or below requirement under the new JIS standards and ø11 requirement for the new motor standards are the same as the old JIS standards (class 2).

*For AL-035, the tolerance is +0.05+0 regardless of bore diameter. The set screw size is M3.

Distance from set screw edge

| Model | AL-035 | AL-050 | AL-070 | AL-075 | AL-090 | AL-095 | AL-100 | AL-110 |

|---|---|---|---|---|---|---|---|---|

| Distance from set screw edge C [mm] | 3.5 | 7.5 | 9 | 10 | 12 | 12 | 12 | 15 |