Mitsuboshi Office Automation & Home Appliance Machinery Belts

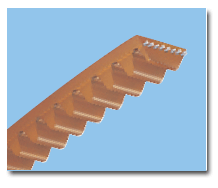

Positive Drive

S1.5M, S2M, S3M, S5M

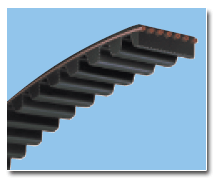

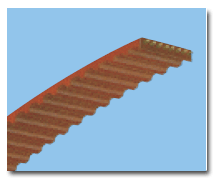

SUPER TORQUE GN

Consisting of round shape tooth profile, this belt is best suited to high precision, smooth drives for computers, OA equipment, etc.

- Flexible belt permits smaller pulley diameters.

- Smooth for noiseless engagement with pulleys.

- Useful for lower shaft load drives.

- Larger torque can be transmitted by smaller size belt.

S2M, S3M, S5M, ST80, ST83, ST111, MXL, XL, T83, T111, XXL

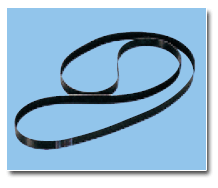

BARE BACK

No rubber coated on tooth fabric to reduce dust and noise. Suitable for use in clean environments.

- Since almost abrasion rubber powder comes off during operation, drive units and peripheral areas./li>

- Since pulleys are almost free from rubber dust, smooth engagement with pulleys can be obtained.

- Lower friction coefficient offers noiseless operation.

- Sutable for OA, FA equipment, household electric and other precision machines.

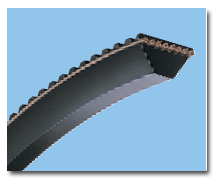

MXL, XL, L

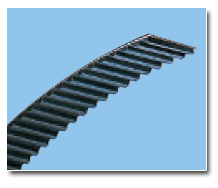

TIMING BELT G

Synchronous drive belt that resolves the problems raised by chain and gear drives.

Shorter tooth pitch belts are suitable for precision devices and information apparatuses.

- Light-weight, thin and flexible belt permits space saving drive design.

- Offers high efficiency, high speed drives.

- Lower noise as compared to chain and gear drives.

- Maintenance-free.

S1.5M, S2M, S3M

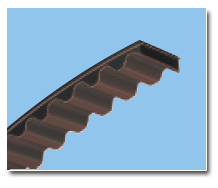

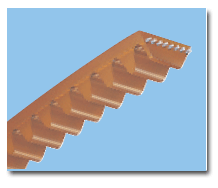

SUPER TORQUE U

Consisting of round shape tooth profile and polyurethane, this belt is suitable for clean drive and OA equipments etc.

- Flexible belt permits smaller pulley diameters.

- Smooth for noiseless engagements with pulleys.

- This belt has fine appearance and does not stain peripheral devices.

- The most suitable is for high precision and light duty power transmission.

T80

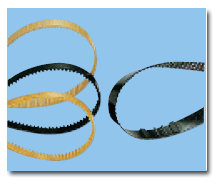

TIMING BELT U

Polyurethane belt suitable for use in clean environment

- Best suited to high precision, light duty power transmissions.

- Suitable for paper feeding, since this belt has a fine appearance and does not stain peripheral devices.

- Since no rubber powder comes off, clean transmissions can be obtained.

- Special belt configurations are available on request.

T80, T83, T111

ST55, ST64, ST80, ST83, ST111, ST1.5, ST2.0

STARMAX G

Since the ST profiles are designed for smooth meshing by reduing interference between belt and pulley at meshing and have almost zero backlash, these belts are suitable for use in accurate positioning.

- Flexible belt permits smaller pulley diameter.

- Larger torque can be transmitted by smaller size belt.

- Suitable for printer carriage drive.

T80, T83, T111

ST83, ST111

STARMAX U

Since the ST profiles are designed for smooth meshing by reducing interference between belt and pulley at meshing and have almost zero backlash, these belts are suitable for use in accurate positioning.

- Dust free, clean drive.

- Flexible belt permits smaller pulley diameter.

- Suitable for printer carriage drive.

Frictional Drive

HB, JT, JBT

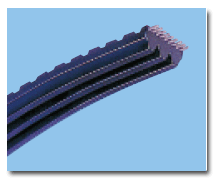

RIBSTAR U

Polyurethane belt with advantages of both flat belt and V-belt.

- Since nylon cord is used as tensile member, this belt is flexible and can be used with small diameter pulleys (20 mm min.) Less bending fatigue.

- Offers smoother rotation with minimum vibration.

- Suitable for high speed drives.

- Abrasion, oil and ozone resistance.

M

POLYURETHANE V

Transparent polyurethane belt with tension member of strong, low stretch synthetic cords.

- Minimizes rubber dust generation.

- Wear resistance. Minimizes rubber dust. Offers clean drives.

- Oil resistance.

- Highly abrasion resistance in spite of higher coefficient of friction.

Single cogged type (MB)

POLYURETHANE MB

Small size, light duty transparent polyurethane belt.

- Higher flexibility allows smaller pulley diameters.

- Higher abrasion resistance offers clean drives.

- Oil resistance.

3M, 5M, 7M

POLYMAX

60o angle series wide angle Polyurethane V belt.

- Suitable for high speed, smooth operations with minimum vibration.

- Allows space saving drives design.

- Lower stretch provides maintenance-free operations.

- Weather resistance and long service life.

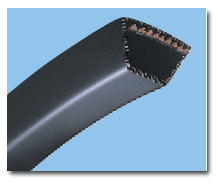

M, A, B

STANDARD V

Most widely used power transmission belt. Economical, and easily available for replacement.

M, A, B

BARE BACK V

Minimum quantity of rubber is attached to belt surface.

- Rubber abrasion is minimized. Keeps machines and peripheral areas clean.

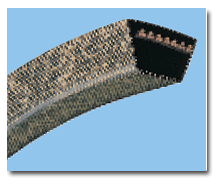

3L, 4L, 5L

FHP

Fight duty V-belt with reduced thickness.

- Highly flexible. Suitable for back side idler applications.

- Allows smaller pulley diameters compared to drives with standard V-belts.