Tsubaki Shock Monitor TSM4000M2

For machine tools. Integral power type

Detects overload and tool wear by integrating one cycle of power from the manufacturing process.

Features

- With the constant pressure of a finishing machine, even if the tool wears, the load ratio does not rise while the machining time increases. This is monitored in the power consumption (area).

- After machining is completed, the wear is detected by the upper limit of power integration (OUT2), while the drill breakage can be detected by the lower limit (OUT1).

- With the instantaneous value of OUT3, overload due to jams is monitored with the absolute value.

- As a set, there are a maximum of 8 types that OUT1, OUT2 and OUT3 can be switched between externally. It accommodates the change of tools and workpieces.

- The integral time setting can be changed easily.

TSM4000M2 Basic Operation

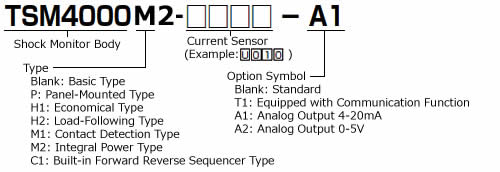

Reference Number System