TSUBAKI Sprockets for Drive Chains

Lock Sprockets

Frictional force on the tapered sleeve locks sprockets to the shaft with no keys. Phasing is also easy.

S Type

Tight locking with bolts and compatible with a wide range of shaft diameters.

Type

Easy locking with nuts and compatible with small diameter shafts.

Lock Sprocket Features

S Type (available chain sizes: RS35 to RS100)

- There is no backlash after mounting (locking). Phase alignment is also easy.

- Can be mounted or removed with just the bolts.

- Sprocket is locked in the thrust direction, making sprocket retainers unnecessary.

N Type (available chain sizes: RS35 to RS60)

In addition to the features of the S Type sprockets, N Type sprockets also possess the following features.

- Compared to S Types, which require you to fasten several bolts, N Types can be locked to the shaft by just fastening nuts. This makes removing and reattachment for minor adjustments easy.

- Tsubaki offers lock sprockets with a minimum bore diameter of 7mm to a max of 28mm standard to satisfy any requirement.

- Designed for strength with the chain’s maximum allowable load in mind — a compact design with minimal waste.

When Using Lock Series RS Sprockets

Please confirm the following points before considering Lock Series sprockets.

*Allowable transmission torque

Ensure that the load torque does not exceed the specified transmission torque in the dimensions/specs table.

*Shaft diameter tolerance and surface roughness

Use a shaft diameter tolerance of H8 and a surface roughness of Ra3.2 as your standards.

*Mounting to shafts provided with keyways or notched shafts.

The allowable transmission torque will decrease by 10% when mounting the sprocket to a shaft provided with a finished keyway, such as a motor shaft, or to a notched shaft.

*Mounting to cold finished carbon steel bars

The allowable torque will decrease by 10% when mounting the sprocket to a cold finished carbon steel bar (drawn steel with an allowable diameter of 8 to 10 class).

*Shaft material

Ensure that the shaft is a solid shaft using S35C grade or higher steel.

*Operating temperature range

-20ºC to 200ºC

Bolt tightening Always use a torque wrench and tighten completely to a specified tightening torque when tightening bolts/nuts. Be sure to check the instruction manual when mounting.

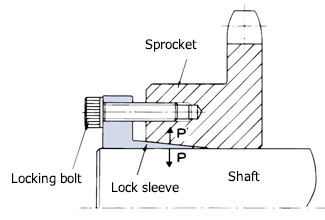

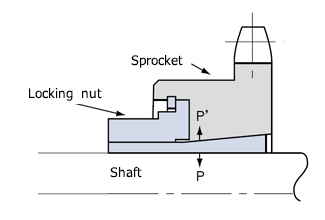

Locking principle

The inner diameter of the sprocket and the outer diameter of the lock sleeve are tapered. When locking bolts (nuts) are tightened, sprockets will slide and move up on the tapered surface. A wedge action will generate force P and P’ in the radial direction to press on the shaft and tapered inner side, and frictional force will tightly lock the sprocket and shaft.

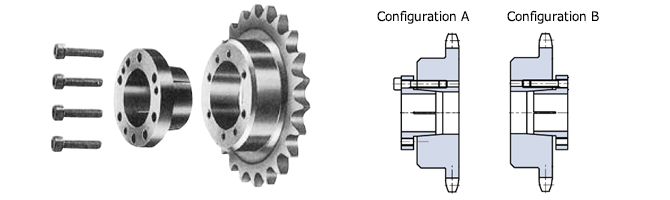

Structure of S type and sleeve mounting type

Points of caution regarding sleeve mounting types

- RS35-1B19TQ-S33_ _ _

- RS40-1B15TQ-S33_ _ _

*The above models can use hub A only, as hub B will cause interference with the chain.

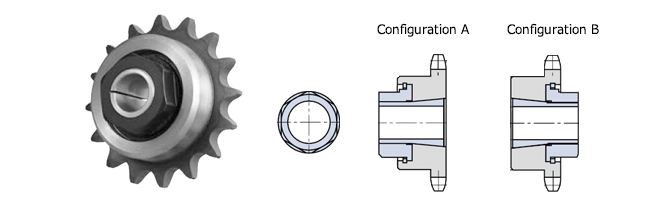

Appearance of N type and sleeve mounting type

Reference Number System (S Type)

| RS40 | – | 1B | 21T | Q | – | S4 | 8 | 25 | A |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

(1) Chain No

(2) Hub type: 1B = Only single hubs are available

(3) No. of teeth

(4) Q: Hardened teeth type

(5) Sleeve frame No. (S4 model number)

(6) No. of mounting Bolts

(7) Bore diameter mm

(8) Mounting type

*(5) to (8) Sleeve model numbers

Reference Number System (N Type)

| RS40 | – | 1B | 21T | Q | – | N4 | 17 | A |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) |

(1) Chain No

(2) Hub type: 1B = Only single hubs are available

(3) No. of teeth

(4) Q: Hardened teeth type

(5) Sleeve frame No. (N4 model number)

(6) Bore diameter mm

(7) Mounting type

*(5) to (7) Sleeve model numbers

Dimensions/Specifications

| Chain Size | Lock Sprocket Type | |

|---|---|---|

| RS35-1B | S Type | N Type |

| RS40-1B | S Type | N Type |

| RS50-1B | S Type | N Type |

| RS60-1B | S Type | N Type |

| RS80-1B | S Type | |

| RS100-1B | S Type | |