Mitsubishi FR-E700 Series

Simple, powerful, and compact inverter

Features

Pursuing the best performance—top level of driving performance in a compact body

- Advanced magnetic flux vector control enables accurate start-ups for general-purpose industrial machines. (200% 0.5Hz (3.7K or lower))

- Improved short-time permissible overload (200% for 3s) provides powerful and consistent driving.

- Torque limit and current limit functions are available.

Easy-to-use (Outstanding operability and diverse expandability)

- The non-slip, adaptable scroll speed setting dial allows for quick jumps or precise increments based on turning speed.

- The operation mode can be selected in simple steps.

- This series has USB which enables easy setting from a personal computer with FR Configurator.

- Plug-in options are available to add digital inputs/analog outputs and to support different communication networks.

- For the customers who need more than the standard terminals, the option terminal blocks, such as the 2-port RS-485 terminal block, are available.

- The inverters with 0.4K or higher capacity have plug-in regenerative brake transistors, which enable use for lift applications.

- An enclosure surface operation panel can be attached on an enclosure surface and is available as an option.The operation panel of the FR-E500 series can be also connected.

Compact and space-saving

- The mounting dimensions are the same as the conventional FR-E500 model to keep backwards compatibility.

- Space can be saved with the side-by-side installation.

Improved reliability and easy maintenance

- Spring clamp terminals provide high reliability and easy wiring. (FR-E700-SC/NF/NC)

- Shutoff circuit (hardware) securely provides emergency output shutoffs.

The inverter with the safety stop function can comply with the safety standards without incurring too much cost. (FR- E700-SC/NF/NC) - The lives of the cooling fan and capacitor have been extended.

- Using the self-diagnosis function, the part life warning can be output and the degree of deterioration can be monitored to prevent malfunction.

- The removable control circuit terminal block simplifies replacement work.

Environmentally friendly

- Filter options reduce the electromagnetic noise generated at the inverter and enables compliance with the harmonic suppression guidelines of Japan.

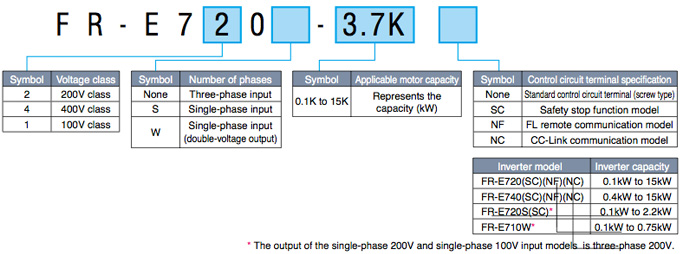

Model

Specifications

| Control method | Soft-PWM control, high carrier frequency PWM control (V/F control, General-purpose magnetic flux vector control, Advanced magnetic flux vector control or Optimum excitation control can be selected) |

|---|---|

| Starting torque | 200%0.5Hz (3.7K or lower) 150% 0.5Hz (5.5K or higher) with Advanced magnetic flux vector control |

| Output frequency range | 0.2 to 400Hz |

| Regenerative braking torque *1 |

0.1K/0.2K·····150%, 0.4K/0.75K·····100%, 1.5K·····50%, 2.2K or higher·····20% |

| Acceleration/deceleration time setting | 0 to 3600s (up to two types of accelerations and decelerations can be set individually.) |

| Multi-speed | 15 speeds |

| Speed command *2 | 0 to 5VDC, 0 to 10VDC, 4 to 20mA, digital setting with setting dial, 0±10VDC (when using optional analog terminal block), digital setting with operation panel or parameter unit, pulse input (when using optional pulse train terminal block) |

| Safety stop *3 | Output shutoff S1 and S2 |

| Alarm output *4 | 1 changeover contact (230VAC 0.3A, 30VDC 0.3A), open collector output |

| Output signal *4 | Two types of open collector outputs and one type of contact output (1 changeover contact) can be selected from inverter running, up to frequency, frequency detection, output current detection, operation ready, overload warning, fault output, and alarm, etc. |

| Monitor function | One monitored item can be selected from output frequency, motor current (steady or peak value), output voltage, frequency setting value, motor torque, converter output voltage, regenerative brake duty, and output power, etc. Pulse train output (1440 pulse/s 1mA)*5, analog output 0 to 10VDC (when using optional analog terminal block), pulse output (when using optional pulse train terminal block) |

| Restart after instantaneous power failure | Available (reduced voltage method (frequency search selectable)) |

| Removable terminal block | Used for control circuit terminals |

| Communication function | RS-485 supported (Modbus-RTU) as standard. CC-Link, PROFIBUS-DP, DeviceNetTM, LONWORKS® options available. FL remote communication and CC-Link communication models also available. |

*1: Braking torque is the average short-time torque when a motor decelerates to a stop from 60Hz in the shortest time. (It varies with the motor loss.) It is not a continuous regenerative torque. The average deceleration torque becomes lower when a motor decelerates from a frequency higher than the base frequency.The inverter is not equipped with a built-in brake resistor. Use an optional brake resistor for an operation with large regenerative power. (Not available for 0.1K and 0.2K.) Brake unit (FR-BU2) can be also used.

*2: For the FL remote communication model, commands can be input from the operation panel or through FL remote communication. For the CC-Link communication model, commands can be input from the operation panel or through CC-Link communication.

*2: For the FL remote communication model, commands can be input from the operation panel or through FL remote communication. For the CC-Link communication model, commands can be input from the operation panel or through CC-Link communication.

*3: Not available for the standard model.

*4: The FL remote communication model and the CC-Link communication model have only one open collector output terminal. (For the FL remote communication model, the terminal is fixed to output the safety monitor output signal (not selectable). )

*5: Not available for the FL remote communication model and the CC-Link communication model.

*4: The FL remote communication model and the CC-Link communication model have only one open collector output terminal. (For the FL remote communication model, the terminal is fixed to output the safety monitor output signal (not selectable). )

*5: Not available for the FL remote communication model and the CC-Link communication model.