MOL-C

Flexible coupling – Oldham – type – Set screw type/Clamping type

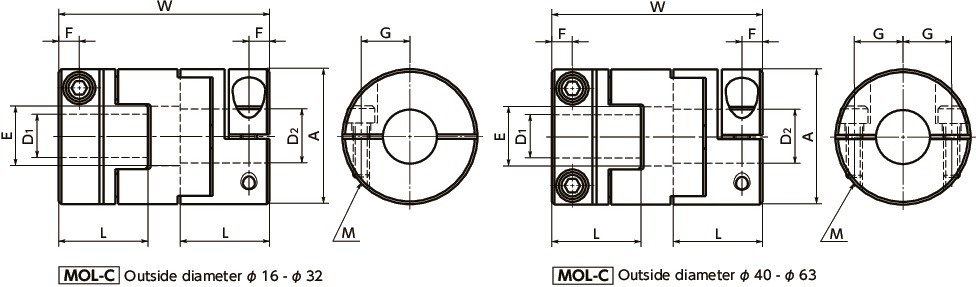

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | L | W | E | F | G | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|---|---|---|

| MOL-16C | 16 | 12.5 | 29 | 7 | 3 | 5 | M2.5 | 1 |

| MOL-20C | 20 | 14.4 | 33.8 | 9 | 3 | 6.5 | M2.5 | 1 |

| MOL-25C | 25 | 16.5 | 39.2 | 11 | 3.8 | 9 | M3 | 1.5 |

| MOL-32C | 32 | 18.7 | 44.7 | 14.5 | 4.5 | 11 | M4 | 2.5 |

| MOL-40C | 40 | 23 | 50 | 17 | 7 | 13 | M5 | 4 |

| MOL-50C | 50 | 27 | 58.2 | 23 | 8 | 16 | M6 | 8 |

| MOL-63C | 63 | 33 | 70.6 | 28 | 10 | 21 | M8 | 16 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque* (N・m) | Max. Rotational (min-1) | Static Torsional Stiffness (N・m/rad) | Max. Lateral Misalignment (mm) | Max. Angular Misalignment (°) | Mass** (g) |

|---|---|---|---|---|---|---|---|---|

| MOL-16C | 6 | 0.7 | 1.4 | 39000 | 31 | 1 | 3 | 12 |

| MOL-20C | 8 | 1.2 | 2.4 | 31000 | 60 | 1.5 | 3 | 19 |

| MOL-25C | 10 | 2 | 4 | 25000 | 140 | 2 | 3 | 36 |

| MOL-32C | 14 | 4.5 | 9 | 19000 | 280 | 2.5 | 3 | 69 |

| MOL-40C | 16 | 9 | 18 | 15000 | 540 | 3 | 3 | 130 |

| MOL-50C | 20 | 18 | 36 | 12000 | 820 | 3.5 | 3 | 230 |

| MOL-63C | 25 | 36 | 72 | 10000 | 1900 | 4 | 3 | 450 |

*Adjustment of rated and max. torque specifications for load fluctuations is not required.

However, if operating temperature exceeds 30℃, please adjust rated torque and max. torque as detailed in the table below.

The operational temperature range for MOS is -20℃ to 80℃. For more detailed information, please refer to Selection Guidelines [PDF 171KB].

**Based on the max. shaft bores.

| Part Number | Stock Bores D1-D2 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 6.35 | 8 | 9.525 | 10 | 12 | 14 | 15 | 16 | 18 | 20 | 25 | |

| MOL-16C | ● | ● | – | – | – | – | – | – | – | – | – | – | – | ||

| MOL-20C | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | ||

| MOL-25C | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | ||

| MOL-32C | – | – | – | ● | ● | ● | ● | ● | – | – | – | – | – | ||

| MOL-40C | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | ||

| MOL-50C | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | ||

| MOL-63C | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | ||

●All products come with set screws (MOS) or cap screws (MOS-C).

●Tolerance of shaft bore on MOS-8 is H8.

●Recommended tolerance for shaft diameters is h6 and h7.

●Bore and keyway modifications are available on request. Please take advantage of our bore modification services.

For more information please refer to Custom Bore Modifications [PDF 495KB].

Material/Finish

| MOL/MOL-C/MOS/MOS-C | |

|---|---|

| Hub | A2017 Alumite Treatment |

| Spacer | Polyacetal |

| Hex Socket Set Screw | SCM435 Ferrosoferric oxide film |

| Hex Socket Head Cap Screw | SCM435 Ferrosoferric oxide film |

Structure

Set Screw type

MOL Outside diameter φ16-φ32 MOL,MOL-C

MOL Outside diameter φ40-φ63

MOS MOS MOS-C

Clamping type

MOL-C Outside diameter φ16-φ32 MOL,MOL-C

MOL-C Outside diameter φ40-φ63

MOS-C MOS MOS-C

Characteristics

- Applicable motors

MOL MOS Servomotor – – Stepping Motor ○ ○ General-purpose motor ◎ ◎ ◎: Excellent ○: Very good

- Property

MOL MOS Allowable Misalignment ◎ ◎ Electrical insulation ◎ ◎ Allowable operating temperature -20℃ to 80℃ -20℃ to 80℃ ◎: Excellent ○: Very good

- This is an oldham-type flexible coupling.

- Slippage of hubs and a spacer allows large eccentricity and angular misalignment to be accepted.

- The load on the shaft generated by misalignment is small and the burden on the shaft is reduced.

- It has electrical insulation.

- Standard type MOL and short type MOS are available.

Application

Parts feeder/Transport device

Ambient Temperature / Temperature Correction Factor

| Ambient temperature | Temperature correction factor |

|---|---|

| -20℃ to 30℃ | 1.00 |

| 30℃ to 40℃ | 0.80 |

| 40℃ to 60℃ | 0.70 |

| 60℃ to 80℃ | 0.55 |

Comparison of rated torque