MRG

Rigid coupling – Set screw type

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | W | F | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|

| MRG-16 | 16 | 24 | 6 | M3 | 0.7 |

| MRG-20 | 20 | 30 | 7 | M3 | 0.7 |

| MRG-25 | 25 | 36 | 9 | M4 | 1.7 |

| MRG-32 | 32 | 41 | 10 | M4 | 1.7 |

| MRG-40 | 40 | 44 | 10.5 | M5 | 4 |

| MRG-50 | 50 | 53 | 12 | M6 | 7 |

| MRG-65 | 65 | 65 | 16 | M8 | 15 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque* (N・m) | Max. Rotational (min-1) | Mass** (g) |

|---|---|---|---|---|---|

| MRG-16 | 8 | 1 | 2 | 39000 | 11 |

| MRG-20 | 10 | 2.5 | 5 | 31000 | 20 |

| MRG-25 | 12 | 4.5 | 9 | 25000 | 39 |

| MRG-32 | 16 | 10 | 20 | 19000 | 71 |

| MRG-40 | 20 | 20 | 40 | 15000 | 114 |

| MRG-50 | 25 | 25 | 50 | 12000 | 215 |

| MRG-65 | 32 | 35 | 70 | 9000 | 450 |

* Correction of rated torque and max. torque due to load fluctuation is not required.

** These are values with max. bore diameter.

| Part Number | Stock Bores D1-D2 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 16 | 18 | 19 | 20 | 25 | 28 | 30 | 32 | |

| MRG-16-3-3 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-3-4 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-3-5 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-3-6 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-4-4 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-4-5 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-4-6 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-5-5 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-5-6 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-16-6-6 | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – |

| MRG-20-6-6 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-20-6-8 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-20-6-10 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-20-8-8 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-20-8-10 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-20-10-10 | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – | – |

| MRG-25-8-8 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-25-8-10 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-25-8-12 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-25-10-10 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-25-10-12 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-25-12-12 | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – | – | – |

| MRG-32-12-12 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-32-12-15 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-32-12-16 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-32-15-15 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-32-15-16 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-32-16-16 | – | – | – | – | – | – | ● | ● | ● | – | – | – | – | – | – | – |

| MRG-40-16-16 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-16-18 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-16-19 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-16-20 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-18-18 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-18-19 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-18-20 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-19-19 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-19-20 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-40-20-20 | – | – | – | – | – | – | – | – | ● | ● | ● | ● | – | – | – | – |

| MRG-50-19-19 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-50-19-20 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-50-19-25 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-50-20-20 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-50-20-25 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-50-25-25 | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | – | – | – |

| MRG-65-28-28 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

| MRG-65-28-30 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

| MRG-65-28-32 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

| MRG-65-30-30 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

| MRG-65-30-32 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

| MRG-65-32-32 | – | – | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● |

All products are provided with hex socket set screws.

In a case where the bore diameter is φ 4 or less, the set screw is used in only one place.

Recommended dimensional allowances of applicable shaft diameter are h6 and h7.

Material/Finish

| MRG/MRG-C/MRG-W | MRGS/MRGS-C/MRGS-W | |

|---|---|---|

| Main Body | A2017 Alumite Treatment | SUS303 |

| Hex Socket Set Screw | SCM435 Ferrosoferric Oxide Film | SUSXM7 |

| Hex Socket Head Cap Screw | SCM435 Ferrosoferric Oxide Film | SUSXM7 |

Structure

Set screw type

MRG Aluminum alloy hub MRG,MRGS

MRGS Made of all stainless steel MRG,MRGS

Clamping type

MRG-C Aluminum alloy hub MRG-C,MRGS-C

MRGS-CMade of all stainless steel MRG-C,MRGS-C

Split type

MRG-W Aluminum alloy hub MRG-W,MRGS-W

MRGS-W Made of all stainless steel MRG-W,MRGS-W

Characteristics

- Applicable motors

MRG MRGS Servomotor ◎ ◎ Stepping motor ◎ ◎ General-purpose motor – – ◎:Excellent ○:Very good

- Property

MRG MRGS Zero Backlash ◎ ◎ High Torque ◎ ○ High Torsional Stiffness ◎ ◎ Corrosion Resistance (All S.S.) – ◎ ◎:Excellent ○:Very good

- These are rigid-type couplings.

- Light weight and ultra small moment of inertia. High response.

- There are two types of units made of aluminum alloy or all stainless steel.

- There are three attachment methods: set screw type, clamping type, and split type.

- Sizes of φ40 – φ65 in outside diameter have been added.

Application

High precision XY stage/Machine tool/Cleaning equipment

Selection

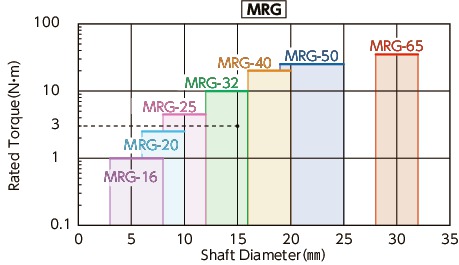

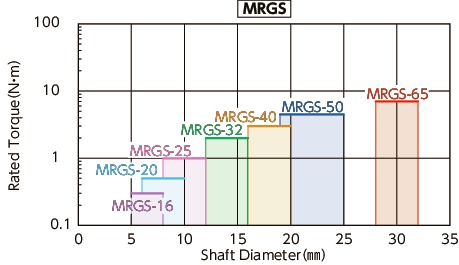

The area bounded by the shaft diameter and rated torque indicates is the selection size.