MSF

Flexible coupling – Serration – type

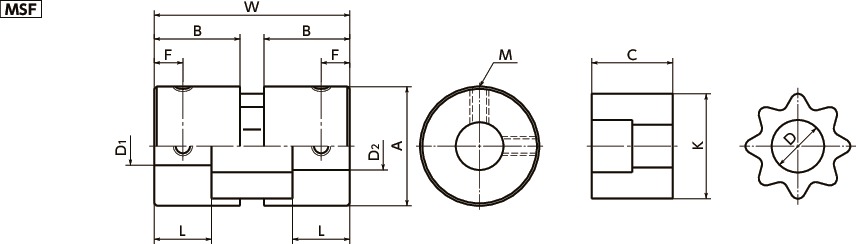

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | B | L | W | F | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|---|---|

| MSF-16 | 16 | 12 | 8 | 27 | 4 | M3 | 0.7 |

| MSF-20 | 20 | 15 | 10 | 34 | 5 | M3 | 0.7 |

| MSF-25 | 25 | 18 | 12 | 41 | 6 | M4 | 1.7 |

| MSF-32 | 32 | 21 | 14 | 48 | 7 | M4 | 1.7 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque*(N・m) | Max. Rotational (min-1) | Static Torsional Stiffness (N・m/rad) | Max. Lateral Misalignment (mm) | Max. Angular Misalignment (°) | Mass** (g) |

|---|---|---|---|---|---|---|---|---|

| MSF-16 | 8 | 0.5 | 1 | 39000 | 4.4 | 0.2 | 2 | 22 |

| MSF-20 | 10 | 1 | 2 | 31000 | 9.5 | 0.2 | 2 | 42 |

| MSF-25 | 12 | 1.5 | 3 | 25000 | 20 | 0.2 | 2 | 81 |

| MSF-32 | 15 | 3 | 6 | 19000 | 52 | 0.2 | 2 | 150 |

*Adjustment of rated and max. torque specifications for load fluctuations is not required.

However, if operating temperature exceeds 30℃, please adjust rated torque and max. torque as detailed in the table below.For more detailed information, please refer to Selection Guidelines [PDF 171KB].

**Based on the max. shaft bores.

| Part Number | Stock Bores D1-D2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 6.35 | 8 | 10 | 12 | 14 | |

| MSF-16 | ● | ● | ● | ● | ● | ● | – | – | – |

| MSF-20 | – | – | ● | ● | ● | ● | ● | – | – |

| MSF-25 | – | – | – | ● | ● | ● | ● | ● | – |

| MSF-32 | – | – | – | – | – | ● | ● | ● | ● |

●All products come with set screws.

●Hubs with shaft bore diameters of φ4 or less have one set screw.

●Recommended tolerance for shaft diameters is h6 and h7.

●Bore and keyway modifications are available on request. Please take advantage of our bore modification services.

For more information please refer to Custom Bore Modifications [PDF 495KB].

| MSF-16-MSF-25 | MSF-32 | |

|---|---|---|

| Casing | ZDC2 Cathodic electrodeposition coating | SMF4040 Steam treatment |

| Sleeve | Polyurethane | Polyurethane |

| Hex Socket Set Screw | SCM435 Ferrosoferric oxide film | SCM435 Ferrosoferric oxide film |

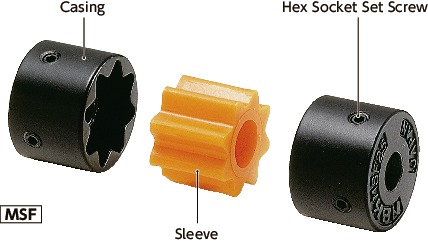

Structure

Set Screw type

Characteristics

- Applicable motors

MSF Servomotor – Stepping Motor – General-purpose motor ◎ ◎: Excellent ○: Very good

- Property

MSF Allowable Misalignment ○ Vibration absorption ○ Electrical insulation ◎ Allowable operating temperature -20℃ to 60℃ ◎: Excellent ○: Very good

- The engagement of serration transmits torque. This is a simple structure flexible coupling.

- It has excellent flexibility. Its max. lateral misalignment and max. angular misalignment are large, absorbing torsional vibration.

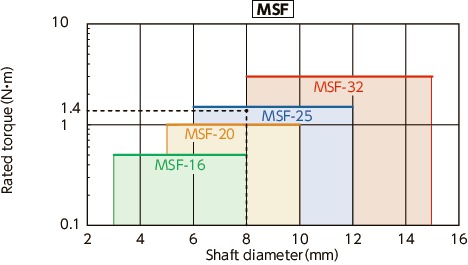

Selection

The area bounded by the shaft diameter and rated torque indicates is the selection size.

Selection example

In case of selected parameters of shaft diameter of φ 8 and load torque of 1.4 N•m, the selection size is MSF-25.

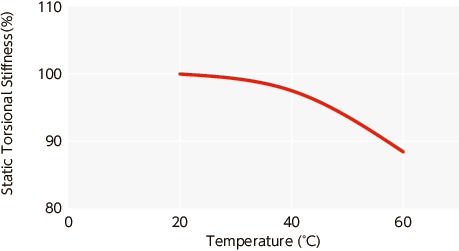

Ambient Temperature / Temperature Correction Factor

| Ambient temperature | Temperature correction factor |

|---|---|

| -20℃ to 30℃ | 1.00 |

| 30℃ to 40℃ | 0.80 |

| 40℃ to 60℃ | 0.70 |

Technical Information

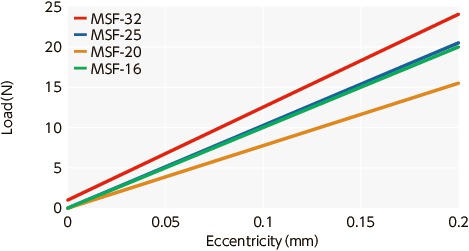

Eccentric reaction force

Change in static torsional stiffness due to temperature

This is a value under the condition where the static torsional stiffness at 20°C is 100%. If the unit is used under higher temperature, be careful about misalignment due to elongation or deflection of the shaft associated with thermal expansion.