MSXP-C

Cleanroom / Vacuum / Heat Resistant Coupling – Slit-type (PEEK) – Clamping Type

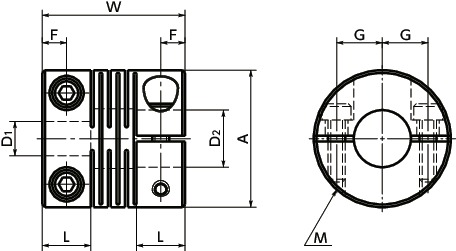

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | L | W | F | G | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|---|---|

| MSXP-25C | 25 | 8.5 | 25 | 4.25 | 8 | M3 | 0.15 |

| MSXP-30C | 30 | 10.2 | 30 | 5.1 | 9 | M3 | 0.15 |

| MSXP-36C | 36 | 12 | 35 | 6 | 11 | M3 | 0.15 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque* (N・m) | Max. Rotational (min-1) | Static Torsional Stiffness (N・m/rad) | Max. Lateral Misalignment (mm) | Max. Angular Misalignment (°) | Max. Axial Misalignment (mm) | Mass** (g) |

|---|---|---|---|---|---|---|---|---|---|

| MSXP-25C | 10 | 0.7 | 1.4 | 25000 | 110 | 0.05 | 0.5 | ±0.1 | 3.8 |

| MSXP-30C | 12 | 1 | 2 | 21000 | 180 | 0.05 | 0.5 | ±0.1 | 6.8 |

| MSXP-36C | 16 | 1.5 | 3 | 17000 | 280 | 0.05 | 0.5 | ±0.1 | 10 |

* Correction of rated torque and max. torque due to load fluctuation is not required.

** These are values with max. bore diameter.

| Part Number | Stock Bores D1-D2 | ||||

|---|---|---|---|---|---|

| MSXP-25C | 6-8 | 6-10 | 8-8 | 8-10 | 10-10 |

| MSXP-30C | 8-8 | 8-10 | 10-12 | 12-12 | |

| MSXP-36C | 10-14 | 12-14 | 14-15 | 15-15 | |

All products are provided with hex socket head cap screw.

Recommended dimensional allowances of applicable shaft diameter are h6 and h7.

In case of mounting on D-cut shaft, be careful about the position of the D-cut surface of the shaft.

Material/Finish

| MSXP-C | |

|---|---|

| Main body | PEEK (Polyether ether ketone) |

| Hex Socket Head Cap Screw | PEEK (Polyether ether ketone) |

Structure

Clamping type

Characteristics

- Property

MSXP Low Particle ◎ Vacuum-supported ○ Less Outgas ○ Heat-resistance ○ Chemical-proof ◎ Zero Backlash ◎ Allowable Misalignment ○ Electrical Insulation ◎ Cleanroom Specification ◎ Allowable Operating Temperature -20℃ to 80℃ ◎: Excellent ○: Very good

- This is a resin spring coupling with single-piece construction. A slit is inserted into a cylindrical material.

- It can be used in an environment or cleanroom where heat resistance and chemical resistance are required, such as FPD manufacturing device.

- PEEK superior in physical and chemical properties is adopted. The amount of outgas is ultralow.

- A plate spring formed by a slit allows eccentricity, angular misalignment, and end-play to be accepted.

Application

FPD manufacturing device/Semiconductor manufacturing device

PEEK’s physical properties

| Property | Test Method | unit | PEEK |

|---|---|---|---|

| Tensile Strength | D638 | N/mm2 | 97 |

| Tensile elongation | D638 | % | 65 |

| Bending Strength | D790 | N/mm2 | 156 |

| Bending elastic modulus | D790 | GPa | 4.1 |

| Izod impact value (with notch) | D256 | J/m | 94 |

| Rockwell hardness | D785 | R / M Scale | M99 |

| Deflection Temperature Under Load (1.82MPa) | D648 | ℃ | 152 |

| Combustibility | UL94 | – | V-0 |

| Dielectric Constant (106 Hz) | D150 | – | 3.3 |

| Dielectric loss tangent (106 Hz) | D150 | – | 0.003 |

| Volume resistivity (x1014) | D257 | Ω・m | 4.9 |

| Insulation Breakdown Strength | D149 | MV/m | 17 |

| Arc resistance | D495 | sec | 23 |

| Specific gravity | D792 | – | 1.3 |

| Water absorption (in 23°C water x 24 h) | D570 | % | 0.5 |

| Content by percentage of glass fiber | – | % | 0 |

Analysis of outgas

| Component | Content | |

|---|---|---|

| Inorganic gas | Hydrogen | 500 or less |

| Carbon monoxide | 500 or less | |

| Carbon dioxide | 500 or less | |

| Organic gas | Methane | 5 or less |

| Ethane | 5 or less | |

| Ethylene | 5 or less | |

| Propane | 5 or less | |

| Acetylene | 5 or less | |

| i-butane | 5 or less | |

| n-butane | 5 or less | |

| Propylene | 5 or less | |

Both inorganic gas and organic gas are not more than the lower limit of determined amount and are not detected.

Measurement Methods

Inorganic gas —- Gas chromatography (TCD)

Organic gas —- Gas chromatography (FID)

Measurement Conditions

Heating temperature —- 100°C

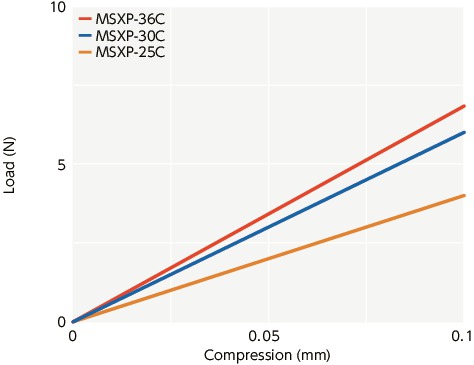

Thrust Reaction Force

Slip Torque

Concerning the sizes shown in the table, please note that the shaft’s slip torque is smaller than the max. torque of MSXP-C.

| Part Number | Bore Diameter (mm) | |||||

|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 14 | 15 | |

| MSXP-25C | 0.5 | 0.6 | 0.7 | |||

| MSXP-30C | 0.8 | 1.1 | 1.5 | |||

| MSXP-36C | 0.7 | 1.2 | 1.8 | 2.2 | ||

These are test values based on the condition of shaft’s dimensional allowance: h7, hardness: from 34-40 HRC, and screw tightening torque of the values described in MSXP-C dimensional table.

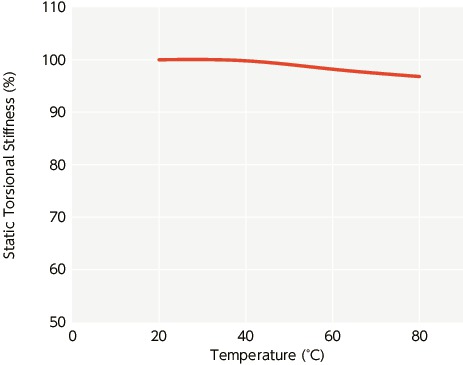

Change in static torsional stiffness due to temperature

Eccentric Reaction Force