SLEC-A-EL

Clamping Screws with Eccentric Head

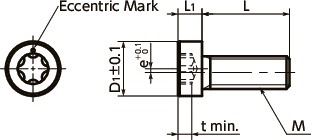

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | e | Key Part No. | Hexalobular Socket No. | t | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|---|

| SLEC-M3-A-EL | 3 | 6 | 6.8 | 2.5 | 0.4 | SKX-10 | 10 | 1 | 1 | 0.7 |

| SLEC-M4-A-EL | 4 | 8 | 7 | 3 | 0.4 | SKX-15 | 15 | 1.2 | 1 | 1.6 |

| SLEC-M5-A-EL | 5 | 10 | 8.5 | 4 | 0.4 | SKX-20 | 20 | 1.5 | 1 | 2.6 |

| SLEC-M6-A-EL | 6 | 12 | 10 | 4 | 0.5 | SKX-25 | 25 | 2 | 1 | 5.1 |

| SLEC-M8-A-EL | 8 | 16 | 13 | 5 | 0.8 | SKX-30 | 30 | 2.5 | 1 | 11 |

| SLEC-M10-A-EL | 10 | 20 | 16 | 7 | 1 | SKX-40 | 40 | 3 | 1 | 22 |

| SLEC-M12-A-EL | 12 | 24 | 18 | 8 | 1 | SKX-45 | 45 | 3.5 | 1 | 32 |

Material/Finish

| SLEC-A | SLEC-A-EL | |

|---|---|---|

| Main Body | SCM435 Ferrosoferric Oxide Coating | SCM435 Electroless Nickel Plating |

| Strength Class | 10.9 | 10.9 |

*The hexalobular shape is prescribed by JIS B 1015:2008(ISO 10664:2005)“Hexalobular internal driving feature for bolts and screws”.

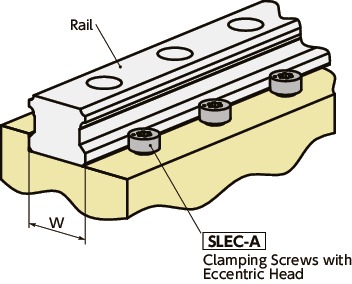

Application

Fixing linear guideway rails, workpieces, and tools

Characteristics

- When the screw is tightened, the workpiece is strongly clamped by the head, which is decentered from the shaft center of the screw. The wedging effect creates a large clamping force with a low tightening torque.

- The screws has a hexalobular socket* that can withstand a high tightening torque.

- Install and remove by using SKX Special Key.

- For fixing linear guideway rails.

- SLEC-A-EL is an electroless nickel(EN)plating type.

For applications that require corrosion resistance. - Also, SLEC-B Clamping Screw with Eccentric Head, which has a guide section below the neck is available.

Usage example

Fixing Linear Guideway Rails

Mounting method

Mounting method

| Part Number | Part Number | E | M | Adjustment Range min./max. |

|---|---|---|---|---|

| SLEC-M3-A | SLEC-M3-A-EL | 3.10~+0.3 | M3 | -0.142857143 |

| SLEC-M4-A | SLEC-M4-A-EL | 3.150~+0.3 | M4 | -0.066666667 |

| SLEC-M5-A | SLEC-M5-A-EL | 3.90~+0.3 | M5 | -0.066666667 |

| SLEC-M6-A | SLEC-M6-A-EL | 4.650~+0.3 | M6 | -0.176470588 |

| SLEC-M8-A | SLEC-M8-A-EL | 6.050~+0.5 | M8 | -0.28 |

| SLEC-M10-A | SLEC-M10-A-EL | 7.50~+0.5 | M10 | -0.333333333 |

| SLEC-M12-A | SLEC-M12-A-EL | 8.50~+0.5 | M12 | -0.333333333 |

Recommended size of linear guideway rail

| Nominal of Rail | Rail Width W | with Clamping Screws with Eccentric Head | |

|---|---|---|---|

| #9 | 9 | SLEC-M3-A | SLEC-M4-A |

| #12 | 12 | SLEC-M3-A | SLEC-M4-A |

| #15 | 15 | SLEC-M3-A | SLEC-M4-A |

| #20 | 20 | SLEC-M4-A | SLEC-M5-A |

| #25 | 23 | SLEC-M5-A | SLEC-M6-A |

| #30 | 28 | SLEC-M6-A | SLEC-M8-A |

| #35 | 34 | SLEC-M8-A | SLEC-M10-A |

| #45 | 45 | SLEC-M10-A | SLEC-M12-A |

| #55 | 53 | SLEC-M12-A |