SPDC-C

Plastic Screw – Socket Head Cap Screws – VESPEL(Grade:SCP-5000)

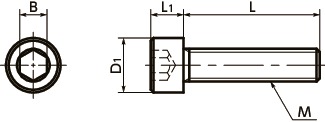

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Torsional Torque (N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|

| SPDC-M3-6-C | 3 | 6 | 5.5 | 3 | 2.5 | 0.21 | 1 | 0.13 |

| SPDC-M3-8-C | 3 | 8 | 5.5 | 3 | 2.5 | 0.21 | 1 | 0.15 |

| SPDC-M3-10-C | 3 | 10 | 5.5 | 3 | 2.5 | 0.21 | 1 | 0.16 |

| SPDC-M3-12-C | 3 | 12 | 5.5 | 3 | 2.5 | 0.21 | 1 | 0.18 |

| SPDC-M3-16-C | 3 | 16 | 5.5 | 3 | 2.5 | 0.21 | 1 | 0.21 |

| SPDC-M4-6-C | 4 | 6 | 7 | 4 | 3 | 0.47 | 1 | 0.28 |

| SPDC-M4-8-C | 4 | 8 | 7 | 4 | 3 | 0.47 | 1 | 0.3 |

| SPDC-M4-10-C | 4 | 10 | 7 | 4 | 3 | 0.47 | 1 | 0.33 |

| SPDC-M4-12-C | 4 | 12 | 7 | 4 | 3 | 0.47 | 1 | 0.36 |

| SPDC-M4-16-C | 4 | 16 | 7 | 4 | 3 | 0.47 | 1 | 0.41 |

| SPDC-M4-20-C | 4 | 20 | 7 | 4 | 3 | 0.47 | 1 | 0.49 |

| SPDC-M4-25-C | 4 | 25 | 7 | 4 | 3 | 0.47 | 1 | 0.58 |

| SPDC-M5-8-C | 5 | 8 | 8.5 | 5 | 4 | 0.98 | 1 | 0.45 |

| SPDC-M5-10-C | 5 | 10 | 8.5 | 5 | 4 | 0.98 | 1 | 0.5 |

| SPDC-M5-12-C | 5 | 12 | 8.5 | 5 | 4 | 0.98 | 1 | 0.54 |

| SPDC-M5-16-C | 5 | 16 | 8.5 | 5 | 4 | 0.98 | 1 | 0.63 |

| SPDC-M5-20-C | 5 | 20 | 8.5 | 5 | 4 | 0.98 | 1 | 0.74 |

| SPDC-M5-25-C | 5 | 25 | 8.5 | 5 | 4 | 0.98 | 1 | 0.88 |

| SPDC-M5-30-C | 5 | 30 | 8.5 | 5 | 4 | 0.98 | 1 | 1 |

| SPDC-M6-10-C | 6 | 10 | 10 | 6 | 5 | 1.65 | 1 | 0.86 |

| SPDC-M6-12-C | 6 | 12 | 10 | 6 | 5 | 1.65 | 1 | 0.93 |

| SPDC-M6-16-C | 6 | 16 | 10 | 6 | 5 | 1.65 | 1 | 1.1 |

| SPDC-M6-20-C | 6 | 20 | 10 | 6 | 5 | 1.65 | 1 | 1.2 |

| SPDC-M6-25-C | 6 | 25 | 10 | 6 | 5 | 1.65 | 1 | 1.4 |

| SPDC-M6-30-C | 6 | 30 | 10 | 6 | 5 | 1.65 | 1 | 1.5 |

| SPDC-M6-40-C | 6 | 40 | 10 | 6 | 5 | 1.65 | 1 | 2 |

| SPDC-M8-10-C | 8 | 10 | 13 | 8 | 6 | 4.04 | 1 | 1.9 |

| SPDC-M8-12-C | 8 | 12 | 13 | 8 | 6 | 4.04 | 1 | 2 |

| SPDC-M8-16-C | 8 | 16 | 13 | 8 | 6 | 4.04 | 1 | 2.2 |

| SPDC-M8-20-C | 8 | 20 | 13 | 8 | 6 | 4.04 | 1 | 2.5 |

| SPDC-M8-25-C | 8 | 25 | 13 | 8 | 6 | 4.04 | 1 | 2.8 |

| SPDC-M8-30-C | 8 | 30 | 13 | 8 | 6 | 4.04 | 1 | 3.1 |

| SPDC-M8-40-C | 8 | 40 | 13 | 8 | 6 | 4.04 | 1 | 3.8 |

* Values in chart are for reference only. They are not guaranteed values.The recommendation torque is 50% of the torsional torque.

Material/Finish

| SPD-C | |

|---|---|

| Main body | VESPEL SP-1 (Non-thermoplastic Polyimide Resin) |

| Heat Resistance Temperature* | 288℃ |

VESPEL is a registered trademark of DuPont.

*This is the value for the plastic material. The maximum operating temperature of the product changes with performance conditions such as tightening torque.

Application

FPD production equipment, semiconductor devices, printed

circuit board etching devices, metallic surface treatment

equipment and facilities, chemical plants, transformers, electrical

and electronic equipment, hot water pumps, and chemical pumps

Characteristics

- VESPEL SP-1 is a non-thermoplastic super-engineering plastic with excellent physical and chemical properties.

- Properties of VESPEL SP-1

- It does not reach a softening point, such as its melting point or glass transition point, even under high temperatures and can be used continually at 288 deg C.

- The screws have excellent chemical resistance, plasma resistance, radiation hardness, and abrasion resistance.

- Thanks to the powder compression molding method, no bubbles blend in and outgas quantity is extremely low.