SPE-LC

Plastic screw – Hex Socket Low Head Bolt – PEEK

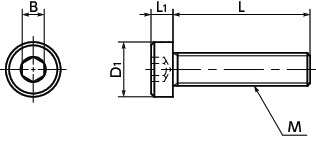

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Tension Rupture Load(N)* | Torsional Torque (N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SPE-M3-6-LC | M3 | 6 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.09 |

| SPE-M3-8-LC | M3 | 8 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.1 |

| SPE-M3-10-LC | M3 | 10 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.12 |

| SPE-M3-12-LC | M3 | 12 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.13 |

| SPE-M3-16-LC | M3 | 16 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.16 |

| SPE-M3-20-LC | M3 | 20 | 5.5 | 2 | 2 | 370 | 0.15 | 10 | 0.2 |

| SPE-M4-6-LC | M4 | 6 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.19 |

| SPE-M4-8-LC | M4 | 8 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.21 |

| SPE-M4-10-LC | M4 | 10 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.24 |

| SPE-M4-12-LC | M4 | 12 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.26 |

| SPE-M4-16-LC | M4 | 16 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.31 |

| SPE-M4-20-LC | M4 | 20 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.38 |

| SPE-M4-25-LC | M4 | 25 | 7 | 2.8 | 2.5 | 730 | 0.54 | 10 | 0.46 |

| SPE-M5-6-LC | M5 | 6 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.26 |

| SPE-M5-8-LC | M5 | 8 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.3 |

| SPE-M5-10-LC | M5 | 10 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.34 |

| SPE-M5-12-LC | M5 | 12 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.38 |

| SPE-M5-16-LC | M5 | 16 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.46 |

| SPE-M5-20-LC | M5 | 20 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.56 |

| SPE-M5-25-LC | M5 | 25 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.69 |

| SPE-M5-30-LC | M5 | 30 | 8.5 | 3.5 | 3 | 1170 | 1.11 | 10 | 0.81 |

| SPE-M6-10-LC | M6 | 10 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 0.58 |

| SPE-M6-12-LC | M6 | 12 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 0.64 |

| SPE-M6-16-LC | M6 | 16 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 0.75 |

| SPE-M6-20-LC | M6 | 20 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 0.88 |

| SPE-M6-25-LC | M6 | 25 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 1.1 |

| SPE-M6-30-LC | M6 | 30 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 1.2 |

| SPE-M6-40-LC | M6 | 40 | 10 | 4 | 4 | 1666 | 1.72 | 5 | 1.6 |

* The values in the table are reference values and are not guaranteed values. The recommended tightening torque is 50% of the twisting rupture torque.

Material/Finish

| SPE-LC | |

|---|---|

| Main body | PEEK (Polyether ether ketone) (Light brown) |

| Heat resistance temperature* | 180℃ |

*A value of plastic materials. The allowable operating temperature of the product varies depending on use conditions such as tightening torque.

Application

FPD production device / Semiconductor manufacturing device /

Print board etching equipment / Metal surface treatment facility /

Chemical plant / Transformer / Electric and electronic device /

Hydrothermal pump / Chemical pump

Characteristics

- Hex socket head cap screw with low head.

- For space-saving of equipment/device and applications with a limited top space.

- PEEK is thermoplastic super engineering plastic superior in physical and chemical properties.

- Excellent chemical resistance. It resists almost all chemicals other than concentrated sulfuric acid, concentrated nitric acid and concentrated hydrofluoric acid.

- It is highly heat-resistant and water-proofed and high temperature strength is retained.

- Features outstanding friction, shock, and fatigue resistance.

- It is highly frame-resistant satisfying V-0 of the UL standard 94.

- Plastic screw properties and precautions for use

Precautions for Use

As PEEK screws are subject to cumulative pitch error during forming, use them in combination with nuts. Otherwise, the fitting with female screws should be 20 mm or below.