SPS-LC

Plastic screw – Hex Socket Low Head Bolt – PPS

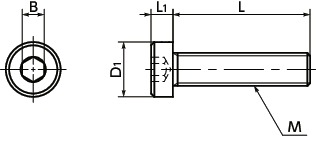

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Tension Rupture Load (N)* | Torsional Torque (N・m)* | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| SPS-M3-6-LC | 3 | 6 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.11 |

| SPS-M3-8-LC | 3 | 8 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.13 |

| SPS-M3-10-LC | 3 | 10 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.15 |

| SPS-M3-12-LC | 3 | 12 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.17 |

| SPS-M3-16-LC | 3 | 16 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.21 |

| SPS-M3-20-LC | 3 | 20 | 5.5 | 2 | 2 | 492 | 0.25 | 10 | 0.25 |

| SPS-M4-6-LC | 4 | 6 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.24 |

| SPS-M4-8-LC | 4 | 8 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.27 |

| SPS-M4-10-LC | 4 | 10 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.31 |

| SPS-M4-12-LC | 4 | 12 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.34 |

| SPS-M4-16-LC | 4 | 16 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.4 |

| SPS-M4-20-LC | 4 | 20 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.49 |

| SPS-M4-25-LC | 4 | 25 | 7 | 2.8 | 2.5 | 789 | 0.46 | 10 | 0.59 |

| SPS-M5-8-LC | 5 | 8 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.38 |

| SPS-M5-10-LC | 5 | 10 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.43 |

| SPS-M5-12-LC | 5 | 12 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.49 |

| SPS-M5-16-LC | 5 | 16 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.59 |

| SPS-M5-20-LC | 5 | 20 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.71 |

| SPS-M5-25-LC | 5 | 25 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 0.88 |

| SPS-M5-30-LC | 5 | 30 | 8.5 | 3.5 | 3 | 1190 | 1.04 | 10 | 1 |

| SPS-M6-10-LC | 6 | 10 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 0.74 |

| SPS-M6-12-LC | 6 | 12 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 0.82 |

| SPS-M6-16-LC | 6 | 16 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 0.96 |

| SPS-M6-20-LC | 6 | 20 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 1.1 |

| SPS-M6-25-LC | 6 | 25 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 1.4 |

| SPS-M6-30-LC | 6 | 30 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 1.5 |

| SPS-M6-40-LC | 6 | 40 | 10 | 4 | 4 | 1811 | 1.7 | 5 | 2.1 |

* The values in the table are reference values and are not guaranteed values. The recommended tightening torque is 50% of the twisting rupture torque.

Material/Finish

| SPS-LC | |

|---|---|

| Main body | PPS (Poly Phenylene Sulfide) (Bright Light Brown) (Glass fiber 40%) |

| Heat resistance temperature* | 200℃ |

*A value of plastic materials. The allowable operating temperature of the product varies depending on use conditions such as tightening torque.

Application

FPD production device / Semiconductor manufacturing device /

Print board etching equipment / Metal surface treatment facility /

Chemical plant / Transformer / Electric and electronic device /

Hydrothermal pump / Chemical pump

Characteristics

- Hex socket head cap screw with low head.

- For space-saving of equipment/device and applications with a limited top space.

- PPS is excellent in heat resistance and chemical resistance and continuously used at 200°C. No fat or organic solvent cannot dissolve PPS at 200℃ or below.

- High strength, high rigidity and high temperature strength is retained.

- It is highly frame-resistant satisfying V-0 of the UL standard 94.

- Plastic screw properties and precautions for use