SNSS-RY

Socket Head Cap Screws – Low Temperature Black Chrome

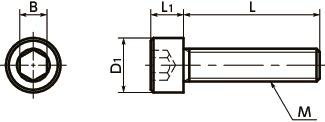

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|

| SNSS-M3-5-RY | 3 | 5 | 5.5 | 3 | 2.5 | 1 | 0.67 |

| SNSS-M3-6-RY | 3 | 6 | 5.5 | 3 | 2.5 | 1 | 0.71 |

| SNSS-M3-8-RY | 3 | 8 | 5.5 | 3 | 2.5 | 1 | 0.8 |

| SNSS-M3-10-RY | 3 | 10 | 5.5 | 3 | 2.5 | 1 | 0.88 |

| SNSS-M3-12-RY | 3 | 12 | 5.5 | 3 | 2.5 | 1 | 0.96 |

| SNSS-M3-16-RY | 3 | 16 | 5.5 | 3 | 2.5 | 1 | 1.2 |

| SNSS-M3-20-RY | 3 | 20 | 5.5 | 3 | 2.5 | 1 | 1.4 |

| SNSS-M4-6-RY | 4 | 6 | 7 | 4 | 3 | 1 | 1.5 |

| SNSS-M4-8-RY | 4 | 8 | 7 | 4 | 3 | 1 | 1.7 |

| SNSS-M4-10-RY | 4 | 10 | 7 | 4 | 3 | 1 | 1.8 |

| SNSS-M4-12-RY | 4 | 12 | 7 | 4 | 3 | 1 | 2 |

| SNSS-M4-16-RY | 4 | 16 | 7 | 4 | 3 | 1 | 2.3 |

| SNSS-M4-20-RY | 4 | 20 | 7 | 4 | 3 | 1 | 2.7 |

| SNSS-M4-25-RY | 4 | 25 | 7 | 4 | 3 | 1 | 3.2 |

| SNSS-M5-8-RY | 5 | 8 | 8.5 | 5 | 4 | 1 | 2.5 |

| SNSS-M5-10-RY | 5 | 10 | 8.5 | 5 | 4 | 1 | 2.7 |

| SNSS-M5-12-RY | 5 | 12 | 8.5 | 5 | 4 | 1 | 3 |

| SNSS-M5-16-RY | 5 | 16 | 8.5 | 5 | 4 | 1 | 3.5 |

| SNSS-M5-20-RY | 5 | 20 | 8.5 | 5 | 4 | 1 | 4 |

| SNSS-M5-25-RY | 5 | 25 | 8.5 | 5 | 4 | 1 | 4.8 |

| SNSS-M6-10-RY | 6 | 10 | 10 | 6 | 5 | 1 | 4.7 |

| SNSS-M6-12-RY | 6 | 12 | 10 | 6 | 5 | 1 | 5.1 |

| SNSS-M6-16-RY | 6 | 16 | 10 | 6 | 5 | 1 | 5.8 |

| SNSS-M6-20-RY | 6 | 20 | 10 | 6 | 5 | 1 | 6.5 |

| SNSS-M6-25-RY | 6 | 25 | 10 | 6 | 5 | 1 | 7.6 |

| SNSS-M6-30-RY | 6 | 30 | 10 | 6 | 5 | 1 | 8.3 |

| SNSS-M8-16-RY | 8 | 16 | 13 | 8 | 6 | 1 | 12 |

| SNSS-M8-20-RY | 8 | 20 | 13 | 8 | 6 | 1 | 13 |

| SNSS-M8-25-RY | 8 | 25 | 13 | 8 | 6 | 1 | 15 |

| SNSS-M8-30-RY | 8 | 30 | 13 | 8 | 6 | 1 | 17 |

| SNSS-M8-35-RY | 8 | 35 | 13 | 8 | 6 | 1 | 19 |

| SNSS-M10-20-RY | 10 | 20 | 16 | 10 | 8 | 1 | 23 |

| SNSS-M10-25-RY | 10 | 25 | 16 | 10 | 8 | 1 | 25 |

| SNSS-M10-30-RY | 10 | 30 | 16 | 10 | 8 | 1 | 28 |

| SNSS-M10-35-RY | 10 | 35 | 16 | 10 | 8 | 1 | 30 |

| SNSS-M10-40-RY | 10 | 40 | 16 | 10 | 8 | 1 | 33 |

Material/Finish

| SNSS-RY | |

|---|---|

| Main Body | SUSXM7(S.S. Grade:A2)Low Temperature Black Chrome Treatment* |

| Strength Class | A2-70 |

*The surface treatment for SNSS-RY has been changed to low temperature black chrome treatment.

Application

Seizing prevention and reflection resistance,

Optical instruments, FPD production equipment,

and semiconductor devices

Characteristics

- Excellent corrosion resistance, chemical resistance, and abrasion resistance.

- Due to low outgas, screws can be used under vacuum environments.

- The coating has excellent lubricating ability and is suitable for prevention of seizing.

- Spectral reflectance is 1.5% or less. These screws are intended for optical instruments and other applications that require antireflection.

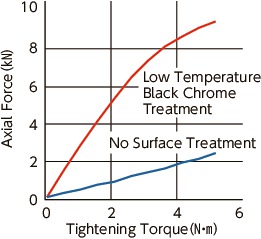

Tightening property (reference)

Part Number:SNSS-M5-25-RY