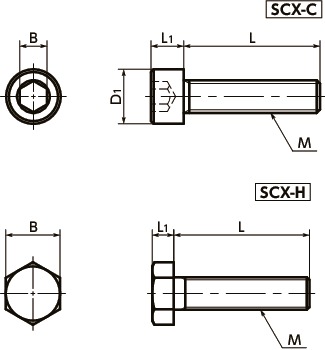

SCX-C

Socket Head Cap Screws/Hex Head Screws – Ceramic

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | D1 | L1 | B | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|---|

| SCX-M3-5-C | 3 | 5 | 5.5 | 3 | 2 | 1 | 0.34 |

| SCX-M3-6-C | 3 | 6 | 5.5 | 3 | 2 | 1 | 0.36 |

| SCX-M3-8-C | 3 | 8 | 5.5 | 3 | 2 | 1 | 0.4 |

| SCX-M3-10-C | 3 | 10 | 5.5 | 3 | 2 | 1 | 0.44 |

| SCX-M4-5-C | 4 | 5 | 7 | 4 | 2.5 | 1 | 0.71 |

| SCX-M4-6-C | 4 | 6 | 7 | 4 | 2.5 | 1 | 0.75 |

| SCX-M4-8-C | 4 | 8 | 7 | 4 | 2.5 | 1 | 0.83 |

| SCX-M4-10-C | 4 | 10 | 7 | 4 | 2.5 | 1 | 0.9 |

| SCX-M4-12-C | 4 | 12 | 7 | 4 | 2.5 | 1 | 0.98 |

| SCX-M4-16-C | 4 | 16 | 7 | 4 | 2.5 | 1 | 1.1 |

| SCX-M4-20-C | 4 | 20 | 7 | 4 | 2.5 | 1 | 1.3 |

| SCX-M4-25-C | 4 | 25 | 7 | 4 | 2.5 | 1 | 1.6 |

| SCX-M5-8-C | 5 | 8 | 8.5 | 5 | 3 | 1 | 1.2 |

| SCX-M5-10-C | 5 | 10 | 8.5 | 5 | 3 | 1 | 1.4 |

| SCX-M5-12-C | 5 | 12 | 8.5 | 5 | 3 | 1 | 1.5 |

| SCX-M5-16-C | 5 | 16 | 8.5 | 5 | 3 | 1 | 1.7 |

| SCX-M5-20-C | 5 | 20 | 8.5 | 5 | 3 | 1 | 2 |

| SCX-M5-25-C | 5 | 25 | 8.5 | 5 | 3 | 1 | 2.4 |

| SCX-M5-30-C | 5 | 30 | 8.5 | 5 | 3 | 1 | 2.8 |

| SCX-M6-10-C | 6 | 10 | 10 | 6 | 4 | 1 | 2.4 |

| SCX-M6-12-C | 6 | 12 | 10 | 6 | 4 | 1 | 2.5 |

| SCX-M6-16-C | 6 | 16 | 10 | 6 | 4 | 1 | 2.9 |

| SCX-M6-20-C | 6 | 20 | 10 | 6 | 4 | 1 | 3.3 |

| SCX-M6-25-C | 6 | 25 | 10 | 6 | 4 | 1 | 3.8 |

| SCX-M6-30-C | 6 | 30 | 10 | 6 | 4 | 1 | 4.2 |

| SCX-M8-12-C | 8 | 12 | 13 | 8 | 5 | 1 | 5.5 |

| SCX-M8-16-C | 8 | 16 | 13 | 8 | 5 | 1 | 6.1 |

| SCX-M8-20-C | 8 | 20 | 13 | 8 | 5 | 1 | 6.7 |

| SCX-M8-25-C | 8 | 25 | 13 | 8 | 5 | 1 | 7.5 |

| SCX-M8-30-C | 8 | 30 | 13 | 8 | 5 | 1 | 8.5 |

| SCX-M10-12-C | 10 | 12 | 16 | 10 | 6 | 1 | 9.5 |

| SCX-M10-16-C | 10 | 16 | 16 | 10 | 6 | 1 | 10 |

| SCX-M10-20-C | 10 | 20 | 16 | 10 | 6 | 1 | 11 |

| SCX-M10-25-C | 10 | 25 | 16 | 10 | 6 | 1 | 13 |

| SCX-M10-30-C | 10 | 30 | 16 | 10 | 6 | 1 | 14 |

Material/Finish

| SCX-C | SCX-H | |

|---|---|---|

| Main Body | Al2O3(99.5% Alumina) | Al2O3(99.5% Alumina) |

Application

FPD production equipment, semiconductor devices, printed circuit board etching devices,

metallic surface treatment equipment and facilities, and chemical plants

Characteristics

- Ceramic made from 99.5% high-purity alumina.

- Usable continually at 1500 deg C.

- Types can be selected by the end symbol of the part number.

SCX-C—- Socket Head Cap Screws

SCX-H—- Hex Head Screws - Excellent heat resistance, chemical resistance, and electrical insulation.

- The properties of ceramic screws⇒The Properties of Ceramic Screws

- Also, ceramics screws with special specifications such as ventilation holes, dimensions, shapes, and cleanroom washing are available. Please contact us for details.

Precautions for Use

- When tightening ceramic screws, use a torque driver or torque wrench and do not exceed the torsional torque. The recommendation torque is 50% of the torsional torque.

M Torsional Torque(N・m) M3 0.04 M4 0.05 M5 0.10 M6 0.15 M8 0.30 M10 0.50 Values in chart are for reference only. They are not guaranteed values.

- Ceramic screws may be damaged by impact. Takecare when handling these screws.