SCX-H

Socket Head Cap Screws/Hex Head Screws – Ceramic

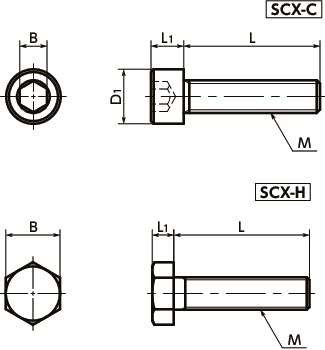

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | M | L | B | L1 | Qty per Pack | Mass (g) |

|---|---|---|---|---|---|---|

| SCX-M3-5-H | 3 | 5 | 5.5 | 2 | 1 | 0.31 |

| SCX-M3-6-H | 3 | 6 | 5.5 | 2 | 1 | 0.34 |

| SCX-M3-8-H | 3 | 8 | 5.5 | 2 | 1 | 0.38 |

| SCX-M3-10-H | 3 | 10 | 5.5 | 2 | 1 | 0.43 |

| SCX-M4-5-H | 4 | 5 | 7 | 2.8 | 1 | 0.66 |

| SCX-M4-6-H | 4 | 6 | 7 | 2.8 | 1 | 0.7 |

| SCX-M4-8-H | 4 | 8 | 7 | 2.8 | 1 | 0.78 |

| SCX-M4-10-H | 4 | 10 | 7 | 2.8 | 1 | 0.86 |

| SCX-M4-12-H | 4 | 12 | 7 | 2.8 | 1 | 0.94 |

| SCX-M4-16-H | 4 | 16 | 7 | 2.8 | 1 | 1.1 |

| SCX-M4-20-H | 4 | 20 | 7 | 2.8 | 1 | 1.3 |

| SCX-M4-25-H | 4 | 25 | 7 | 2.8 | 1 | 1.5 |

| SCX-M5-8-H | 5 | 8 | 8 | 3.5 | 1 | 1.3 |

| SCX-M5-10-H | 5 | 10 | 8 | 3.5 | 1 | 1.4 |

| SCX-M5-12-H | 5 | 12 | 8 | 3.5 | 1 | 1.5 |

| SCX-M5-16-H | 5 | 16 | 8 | 3.5 | 1 | 1.8 |

| SCX-M5-20-H | 5 | 20 | 8 | 3.5 | 1 | 2 |

| SCX-M5-25-H | 5 | 25 | 8 | 3.5 | 1 | 2.3 |

| SCX-M5-30-H | 5 | 30 | 8 | 3.5 | 1 | 2.6 |

| SCX-M6-10-H | 6 | 10 | 10 | 4 | 1 | 2.2 |

| SCX-M6-12-H | 6 | 12 | 10 | 4 | 1 | 2.4 |

| SCX-M6-16-H | 6 | 16 | 10 | 4 | 1 | 2.8 |

| SCX-M6-20-H | 6 | 20 | 10 | 4 | 1 | 3.1 |

| SCX-M6-25-H | 6 | 25 | 10 | 4 | 1 | 3.6 |

| SCX-M6-30-H | 6 | 30 | 10 | 4 | 1 | 4 |

| SCX-M8-12-H | 8 | 12 | 13 | 5.3 | 1 | 5.1 |

| SCX-M8-16-H | 8 | 16 | 13 | 5.3 | 1 | 5.7 |

| SCX-M8-20-H | 8 | 20 | 13 | 5.3 | 1 | 6.4 |

| SCX-M8-25-H | 8 | 25 | 13 | 5.3 | 1 | 7.2 |

| SCX-M8-30-H | 8 | 30 | 13 | 5.3 | 1 | 8 |

| SCX-M10-12-H | 10 | 12 | 16 | 6.4 | 1 | 9.9 |

| SCX-M10-16-H | 10 | 16 | 16 | 6.4 | 1 | 11 |

| SCX-M10-20-H | 10 | 20 | 16 | 6.4 | 1 | 12 |

| SCX-M10-25-H | 10 | 25 | 16 | 6.4 | 1 | 13 |

| SCX-M10-30-H | 10 | 30 | 16 | 6.4 | 1 | 14 |

Material/Finish

| SCX-C | SCX-H | |

|---|---|---|

| Main Body | Al2O3(99.5% Alumina) | Al2O3(99.5% Alumina) |

Application

FPD production equipment, semiconductor devices, printed circuit board etching devices,

metallic surface treatment equipment and facilities, and chemical plants

Application

FPD production equipment, semiconductor devices, printed circuit board etching devices,

metallic surface treatment equipment and facilities, and chemical plants

Characteristics

- Ceramic made from 99.5% high-purity alumina.

- Usable continually at 1500 deg C.

- Types can be selected by the end symbol of the part number.

SCX-C—- Socket Head Cap Screws

SCX-H—- Hex Head Screws - Excellent heat resistance, chemical resistance, and electrical insulation.

- The properties of ceramic screws⇒The Properties of Ceramic Screws

- Also, ceramics screws with special specifications such as ventilation holes, dimensions, shapes, and cleanroom washing are available. Please contact us for details.

Precautions for Use

- When tightening ceramic screws, use a torque driver or torque wrench and do not exceed the torsional torque. The recommendation torque is 50% of the torsional torque.

M Torsional Torque(N・m) M3 0.04 M4 0.05 M5 0.10 M6 0.15 M8 0.30 M10 0.50 Values in chart are for reference only. They are not guaranteed values.

- Ceramic screws may be damaged by impact. Takecare when handling these screws.