BX Series

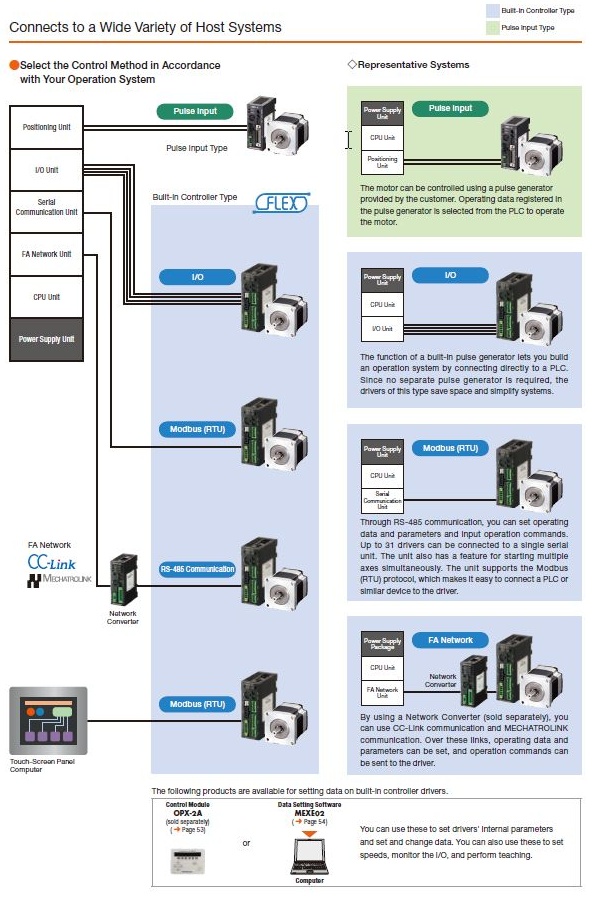

Two types are available: the built-in controller type equipped with interfaces that connect to a wide variety of host systems and the pulse input type that enables the motor to be controlled from a pulse generator provided by the customer.

Built-in Controller Drivers Support FLEX, a Feature That Enables You to Select the Control Method in Accordance with Your Operation System.

What is FLEX?

FLEX is a general name for products that support FA network control via I/O control, Modbus (RTU) control, and network converters. It makes connections and controls easy and reduces the total lead time for building systems.

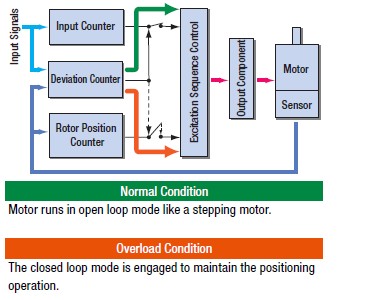

Our Unique Closed Loop Control Providing High Reliability

- Continues Operation Even During Abrupt Load Changes and Accelerations

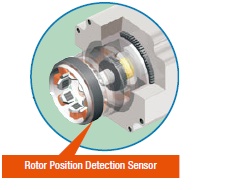

- Rotor Position Detection Sensor (Resolver)

- The sensor is compact and slim, making the overall length of the motor shorter.

- When compared with typical optical encoders, this sensor is superior in heat resistance, vibration resistance, etc.

- As encoder cables are not needed, only a single cable is needed for the connection between the motor and driver.

- Alarm Signal Output in Case of Abnormality

- Also Supports Absolute Systems

- Compact DC Power-Supply Input Driver

- Push-Motion Operation

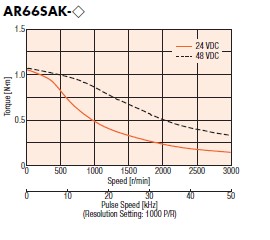

- 48 VDC Compatible

- Position Control in the Same Direction

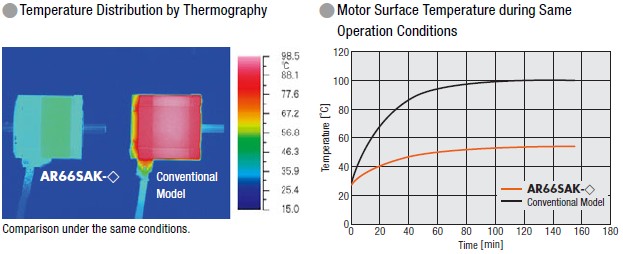

- Lower Heat Generation

- Energy Savings

- Continuous Operation (Operation at high frequency)

During normal operation, the motor operates synchronously with command pulses in open loop mode. When an overload condition is detected, the motor instantly switches to closed loop mode to correct the rotor position.

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, an END signal is output. This ensures the same level of reliability achieved by a servo motor.

You can build an absolute system that detects absolute positions by connecting the accessory battery (sold separately). (available only on the built-in controller type)

Connects to a Wide Variety of Host Systems

Select the Control Method in Accordance with Your Operation System

Highly Functional, Compact Driver

The compact DC power input driver makes it possible to reduce the space needed for installing control boxes and devices. The driver can be mounted directly to a DIN rail, so no screws are necessary.

A force is continuously applied to the load. When contact is made with the load, the motor switches to push-motion operation and applies constant torque to the load.

The motor runs on a 24 VDC or 48 VDC power supply. Choose the power supply that you have available. The torque is higher when 48 VDC is used rather than 24 VDC. (□28 only accepts 24 VDC input.)

The round feature enables you to control positioning even in an application where positioning is repeated in the same direction (available only on the built-in controller type).

✽ Building an absolute system requires an accessory battery (sold separately).

Continuous Operation is Achieved Due to the Reduction of Motor Heat Generation by Utilizing High-Efficiency Technology.

Significant reduction in heat generation has been achieved through high-efficiency technology.

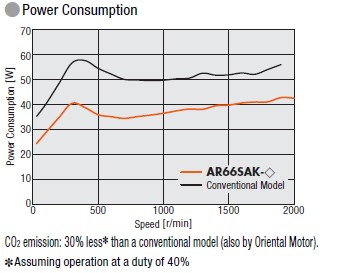

The power consumption is 30% less than a conventional model (also by Oriental Motor).

The AR Series can be operated at high frequency. You can drive the motor continuously.