2D Code Reader LP-ABR10

CE , Korean KC Approved

CE : EMC Directive

Features

DPM 2D Code Reader

DPM (Direct Part Marking) is widely used for production management and quality control. Thus, code readers used for reading 2D codes marked directly on products are becoming much more important than before.

The LP-ABR10 series 2D code reader offers high performance and accurately reads 2D codes marked by laser markers.

Stable Reading Performance Backed by Advanced Features

Code readers used in production lines are required to stably read 2D codes marked on parts of diverse shapes and with various surface conditions.

The LP-ABR10 series code reader is equipped with three advanced features that dramatically improve reading accuracy and ensure stable reading of 2D codes.

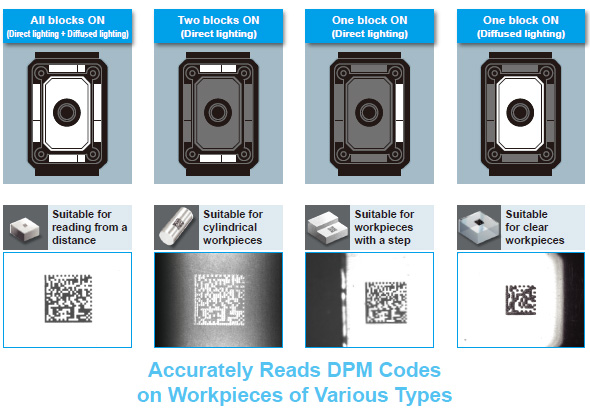

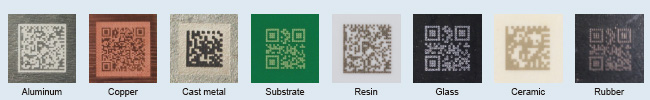

Lighting variations allow selection of optimal lighting condition.

DPM is a process used to directly mark parts with product information. The DPM process adds codes directly on parts made of metals, resins or other materials. Unlike codes printed on paper or labels, DPM codes can be affected by the part shape and surface condition. Thus, the ordinary lighting system of a code reader may not be able to read DPM codes properly in some cases.

The LP-ABR10 series code reader is built in with a diffused lighting block (center block) and four direct lighting blocks (top, bottom, left and right blocks). Each of these lighting blocks can be independently turned on/off, and the brightness can be adjusted in 100 steps. By setting an optimal lighting condition, the LP-ABR10 series code reader reads DPM codes accurately.

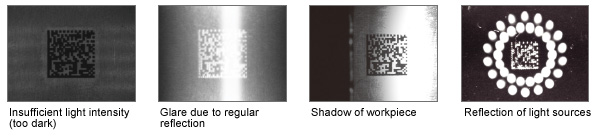

Problems with ordinary lighting

1.2-megapixel image sensor captures clear image.

The LP-ABR10 series code reader is equipped with a high-resolution, 1.2-megapixel CMOS image sensor. It is capable of reading a small cell-size code that is difficult to be read by an ordinary 0.3-megapixel image sensor and a 2D code on a workpiece that generates a lot of noise in code reading.

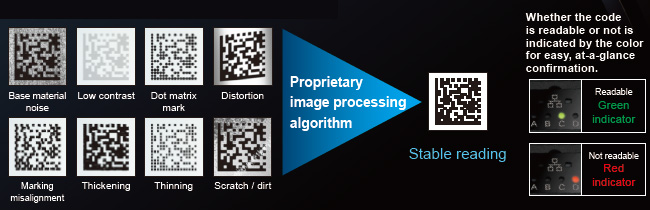

Proprietary algorithm maintains stable reading.

Since DPM codes are directly marked on parts, they can result in the generation of a large amount of noise due to surface irregularities or insufficient contrast against the background. This makes it difficult for an ordinary code reader to read the codes accurately. Codes can also become scratched or covered with oil, and they may be exposed to harsh conditions such as washing and chemical treatment. The LP-ABR10 series code reader is provided with a proprietary code reading algorithm developed exclusively for DPM codes. This enables the LP-ABR10 series code reader to read codes that are difficult for an ordinary code reader to read and ensures stable reading. This contributes to the improvement of production management and traceability of various products.

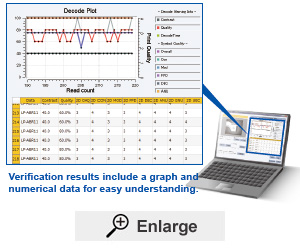

2D Code Marking Quality Verification Function

The LP-ABR10 series code reader supports 2D code marking quality verification in compliance with ISO/IEC 15415 and AIM DPM-1-2006. This enables management of 2D code marking quality using quality items in compliance with the international standards. Management of changes in the 2D code marking quality is useful for preventive maintenance of production lines.

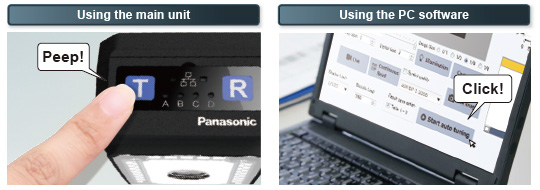

Auto Teaching Function

The auto teaching function automatically sets the most suitable 2D code reading condition. This function allows easy and convenient setting of optimal reading condition for various types of parts.

Auto teaching function for easy setting of reading condition for various types of parts

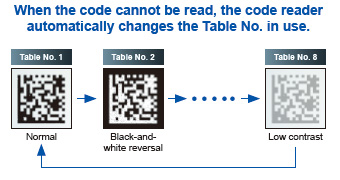

Table Function

The code reader unit can be registered with up to eight sets of conditions. Even when 2D codes with different marking quality levels must be read, the setting automatically changes to an appropriate registered setting. This helps reduce the production line from stopping due to a read error.

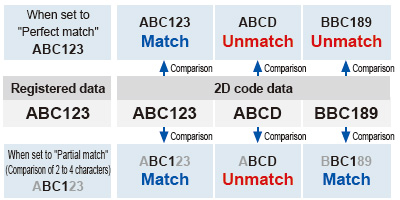

Data Check Function (Preset Mode)

With this function enabled, the code reader compares the 2D code to read with preregistered data and reads it only when the 2D code matches the preset condition. The function has two types of setting, “Perfect match” and “Partial match.” This function helps prevent defect products from mixing with good products.

IP65 Rating

The code reader boasts an IP65 rating (IEC), and prevents entry of dust particles and resists the effect of water droplets.

Ethernet Compatibility

The Ethernet compatibility enables the transmission of not only the read data but also images and quality verification data. The LP-ABR10 series code reader is also equipped with a PLC link function for easy configuration of a network.

DPM (Direct Part Marking) is widely used for production management and quality control. Thus, code readers used for reading 2D codes marked directly on products are becoming much more important than before.

The LP-ABR10 series 2D code reader offers high performance and accurately reads 2D codes marked by laser markers.

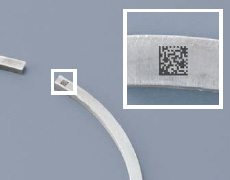

Examples of DPM codes

Engine block

Camshaft

Connecting rod

Piston ring

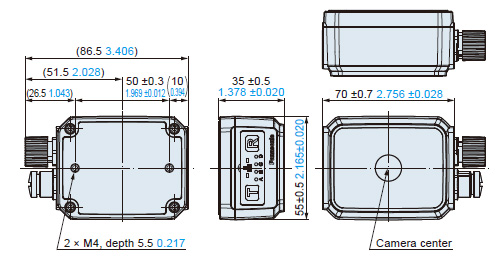

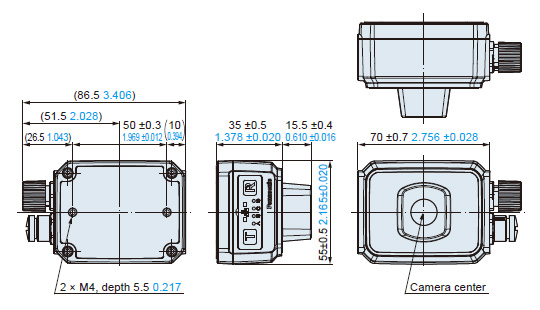

| Type | Standard type | Long-distance type | ||

|---|---|---|---|---|

| Model No. | LP-ABR11 | LP-ABR12 | ||

| Image sensor | 1/3 inches CMOS monochrome | |||

| Effective pixels | 1,280 ? 960 (1.2 million pixels approx.) | |||

| Internal illumination source | White LED | |||

| Reading angle | PITCH: ?35?, SKEW: ?35?, TILT: 360? | |||

| Supply voltage | 24 V DC ?10 % | |||

| Power consumption | Command (SYNC) standby: 140 mA approx.,During reading operation: 400 mA approx. | |||

| Interface | Ethernet | 10Base-T, 100Base-T, 1000Base-T | ||

| RS-232C | 1200 bps to 115.2 kbps | |||

| Digital input | Photo-coupler isolation ? 1(Input resistance: 1 k?, OFF voltage: 0 to 0.8 V, ON voltage: 6 to 28 V) | |||

| Digital output | Photo-coupler isolation ? 4 (Maximum rating: 30 V DC, 50 mA) | |||

| Protection | IP65(IEC) | |||

| Ambient temperature | 0 to +40 ? +32 to +104 ?, Storage: -20 to +65 ? -4 to +149 ? | |||

| Ambient humidity | 35 to 85 % RH (No dew condensation allowed),Storage: 35 to 85 % RH (No dew condensation allowed) | |||

| Vibration resistance | 10 to 55 Hz amplitude 1.5 mm 0.059 in (total width) in X, Y, Z directions for two hours each | |||

| Weight | Net weight: 200 g approx. | |||

LP-ABR12

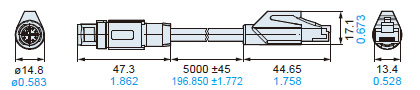

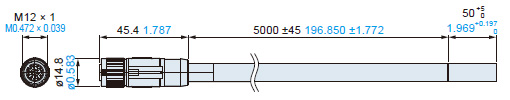

LP-ABR10-C5

LP-ABR10-L5