Compact CO2 Laser Marker LP-GS SERIES

CE , FDA Approved

CE : Low Voltage Directive, EMC Directive

Features

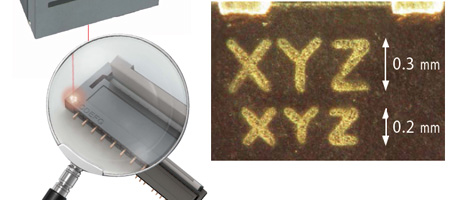

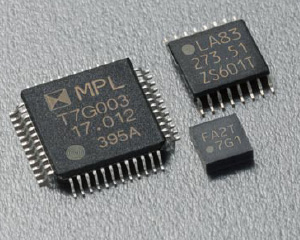

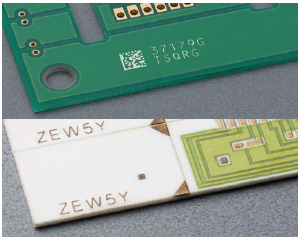

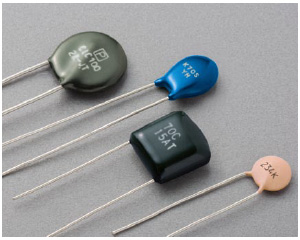

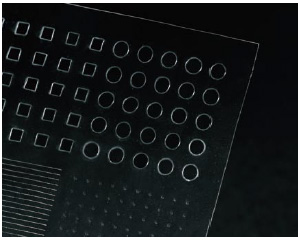

Ultra-small character type [LP-GS052]

Character size 0.2mm or less*0.0079 in or less

The LP-GS052 has been added to the lineup of the compact CO2 laser marker LP-GS series, which can mark ultra-small characters. The CO2 laser marker is now able to mark characters of 0.2 mm 0.0079 in or less in height and width. It enables high-quality marking on more compact and thinner electronic components.

*There are cases that a target object cannot be marked due to its material or marking condition.

The LP-GS052 can mark characters sharply that are so ultra-small that they cannot be seen with the eye alone.

Traceability can be realized even for small components with limited marking space.

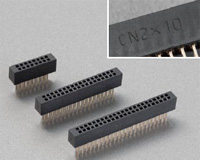

Marking examples

Narrow pitch connector

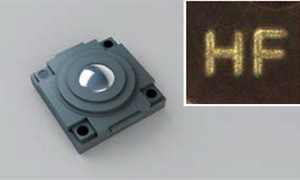

Discrete device

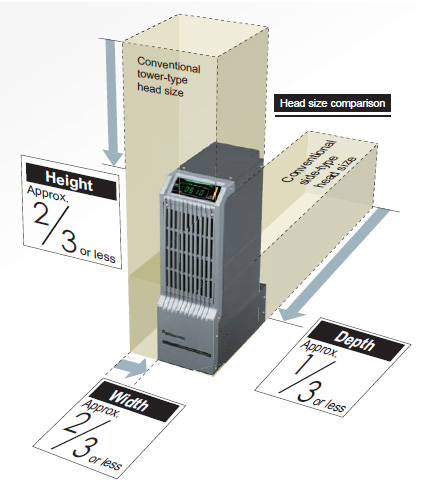

Revolutionary size

Downsized unit

The LP-GS series Laser Marker heads have considerably decreased in size. The controller is also miniaturized so this downsized unit contributes to reduce floor space cost.

Heads can be installed in any direction (Vertical, Horizontal), allowing users design their equipment more flexible.

Marking on a wide area

The LP-GS series head ensures both miniature size with light weight. Moving the head to the marking position ensures high-quality marking over a wide area. Due to the smaller head size, less space for installation is required, even when marking on an M- or L-sized large circuit board. The cable between head and controller is flex-resistant.

Production improvements

Drastic improvements in marking quality and man-hours for setup change

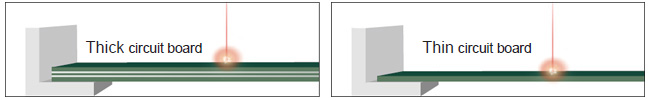

Marking on circuit boards with various thickness

Previously the head height had to be adjusted each time the circuit board thickness was changed. LP-GS series have integrated Z-axis control mechanism which allow adjustment of the work distance based on circuit board thickness.The mechanism both eliminates man-hours to change setup and maintains marking quality stability.

[Example of height control via Z-axis control]

With Z-axis adjustment

Without adjustment

This Z-axis control mechanism helps to improve the production efficiency when marking on not only substrates but also workpieces of various sizes.

IC

Connector

Connector

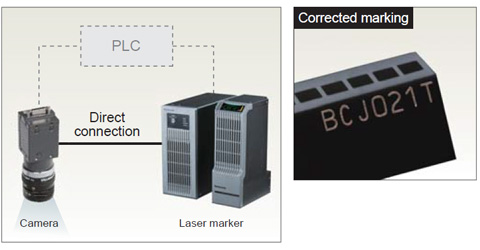

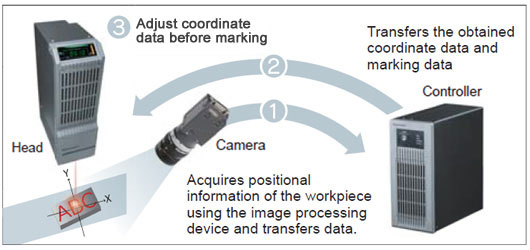

Camera correction without PLC

A camera can be used for adjusting the tilt of the work piece to maintance the marking quality.

Connect the LP-GS series and the camera directly to transfer the correction data from camera to the Laser Marker. In addition, man-hours for PLC programming can be reduced.

Smart operation

Operability that focuses on “easy to use for anyone”

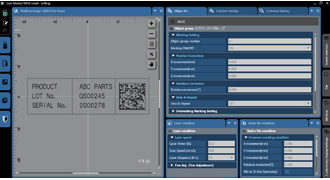

New dedicated software: Laser Marker NAVI smart

Includes the new dedicated PC configuration software Laser Marker NAVI smart. It is compatible with Windows® 8.

When used with a tablet PC*1, touch panel operation becomes possible.

*1 Use a commercially available tablet PC.

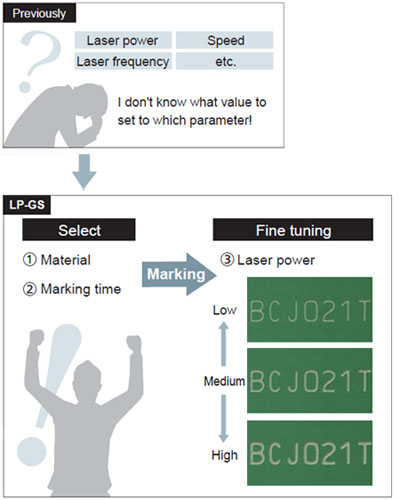

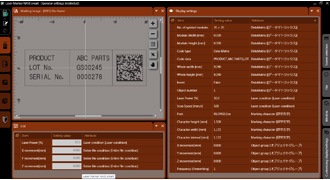

It requires a certain amount of experience to set the optimum conditions for a wide variety of workpieces. So, an assist function has been added to make settings of optimum conditions simply.

Even a beginner can output conditions, greatly shortening the lead time to start production.

Individual screens for different purposes

The “Laser Marker NAVI smart” display can be switched according to user purpose, such as for the “operator” or “supervisor”. The precise screen indication enhances operability when confi guring or checking settings.

The data to be marked can be edited not only previewing it. Even complicated settings can be finely adjusted while previewing the data, which improves the work efficiency.

Equipped with a “watch function” that displays only the necessary parameters while production is in progress. Operator error can be prevented because only the parameters to be changed by the operator are selected and displayed.

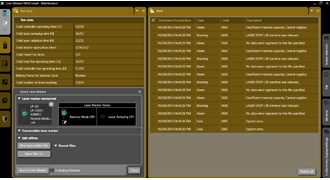

The Laser Marker operation history, error history and other parameters required for stable operation can be confi rmed. This information is useful for making maintenance plans and preparation.

Many convenient functions

“External device link function” – controllable without PLC

Previously, a PLC was required in order to coordinate the Laser Marker with image processing devices and readers. The LP-GS series is capable of direct data processing with certain devices even without a PLC, thanks to the external device link function.

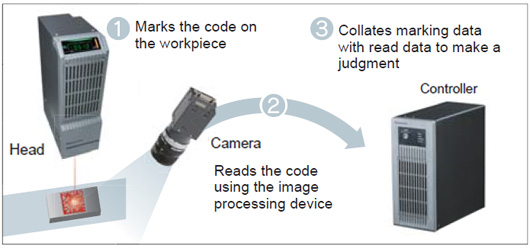

[Link with an image processing device]

The Laser Marker is equipped with a new function that provides direct control of an image processing device (IPD). Now the Laser Marker itself can trigger the IPD to send the workpiece position (coordinate data). As there is no need for a PLC and programming, the amount of man-hours is reduced.

A new function has been added which enables to control a sequence of operations from marking to reading the code. The reader (IPD) reads codes marked by the Laser Marker and collates them with the original data to check whether the code is correctly marked.

This helps to prevent mixup of incorrectly marked products.

The reader (image processing device) reads code marked by the Laser Marker and the Laser Marker collate it with the original data to check whether the code is correctly marked, in order to prevent mixup of incorrectly marked products.

[Link with a code reader]

The laser marker can be controlled by reading code.

Connect the laser marker and code reader directly and read data, such as production instruction, etc. Based on this information, the Laser marker can execute various operations configured beforehand, e.g. change the marking data. Laser Marker controled by code data prevents input error by operator.

IC

Connector

Connector

Connector

Circuit board

Resin molded products

Electronic parts

Outer boxes

Aluminum wrapping materials

Laser label( marking + half-cut)

Film (processing)

Optical fiber (processing)

Camera module

Small push switch

Narrow pitch connector

Discrete device

| Model No. | LP-GS051-F | LP-GS051-LF | |

|---|---|---|---|

| Marking laser | Laser type | CO2 laser, Wavelength: 10,600 nm 0.417 mils, Class 4 laser | |

| Average output*1 | 5W | ||

| Laser oscillation | CW oscillation | ||

| Guide laser | Red semiconductor laser, Wavelength: 655 nm 0.026 mil, Class 2 laser Maximum output: 1 mW or less | ||

| Laser pointer | Red semiconductor laser, Wavelength: 655 nm 0.026 mil, Class 2 laser Maximum output: 1 mW or less | ||

| Scanning method | Galvano-scanning method | ||

| Marking field | 55 x 55 mm 2.165 in x 2.165 in | ||

| Work distance (center position)*2 | 111 mm 4.370 in | ||

| Work distance range | 108 to 114 mm 4.252 to 4.488 in | – | |

| Scan speed*3 | Maximum 3,000 mm/sec. 118.110 in/sec. | Maximum 2,000 mm/sec. 78.740 in/sec. | |

| Registration file quantity | 10,000 files | ||

| Marking data quantity | 2,000/file | ||

| Marking object types | Character types | English uppercase letters, English lowercase letters, numerals, katakana,hiragana, kanji (JIS No. 1 and No. 2 standards), symbols,user-registered characters (up to 50) | |

| Barcodes | Code 39, Code 128, ITF, NW-7, JAN (EAN) / UPC | ||

| 2D codes | QR code, Micro QR code, iQR code, Data Matrix, GS1 Data Matrix | ||

| Graphic data | VEC*4, DXF, BMP, HPGL, JPEG, AI, EPS | ||

| Character height / width*3 | 0.1 to 55 mm 0.004 to 2.165 in | ||

| Marking shape | Straight line, arc, proportional, justify | ||

| Marking condition | Stationary | ||

| I/O ports | I/O terminal (40-pin), I/O connector (40-pin) | ||

| Serial communication interface | EIA-RS-232C, Ethernet | ||

| Power supply | 90 to 132 V AC or 180 to 264 V AC (includes ?10 % voltage fluctuation)*5, frequency 50 / 60 Hz | ||

| Power consumption | At 100 V AC | 370 VA or less (4.2 A or less) | |

| At 200 V AC | 500 VA or less (2.8 A or less) | ||

| Cooling method | Forced air cooling to both head and controller | ||

| Ambient temperature*6 | 0 to +40 ? +32 to +104 ? | ||

| Ambient temperature for storage*6 | ?10 to +60 ? +14 to +140 ? | ||

| Ambient humidity*6 | 35 to 85 % RH | ||

| Main unit net weight | Head | Approx. 11 kg | |

| Controller | Approx. 8 kg | ||

*1 Output at product processing edge (at configured power of 100).

*2 There is an approx. ?0.5 mm 0.020 in individual difference in work distance center position.

*3 Values listed here are the variable range. Setting values that can maintain marking or processing quality differ based on marking conditions and target materials.

*4 VEC is an exclusive laser marker image file format.

*5 Power supply is auto-switching.

*6 Common to controller and head. No dew condensation or icing allowed. If a unit was stored at a temperature other than ambient temperature, sufficient time should be given to reach ambient temperature before use.

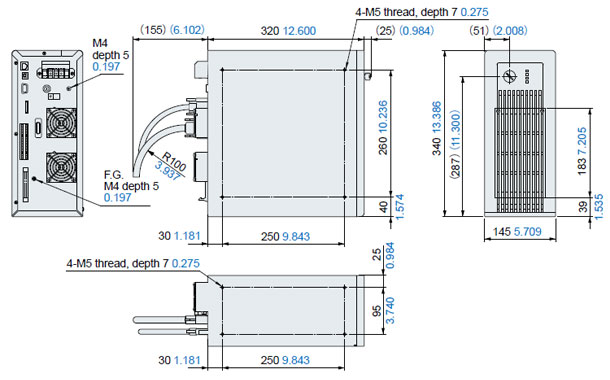

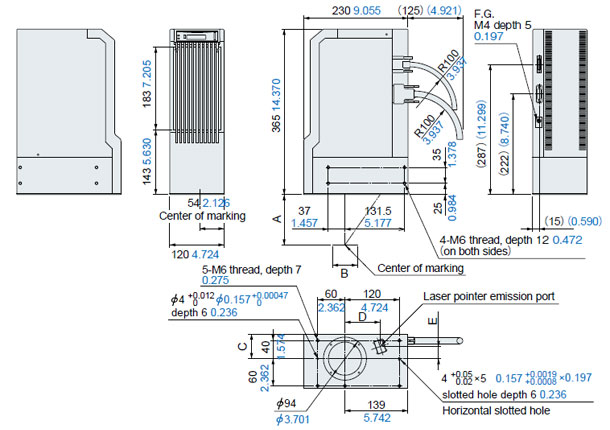

Head

Controller