TSUBAKI Lambda® Chain

Lambda® Chain

We reviewed the material and processing that go into our special oil-impregnated bushes, and improved the lubricant.

Basic Structure of Lambda Chain

Standard specifications

Inner and outer plates are black oxide coated.

Nickel plated specifications

Uses a special nickel plating (except on the bush).

Points of caution

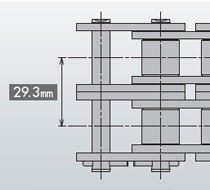

To ensure compatibility with RS Roller Chain, the inner plate is one size thicker with the same tensile strength as RS Roller Chain. Thus, pins are longer than with the RS Roller Chain, so interference with equipment should be checked.

Features of Lambda Chain

Long life, lube free

The special oil impregnated bushes provides long service life, even without additional lubrication.

Improved the lubricant used in the special oil impregnated bushes.

Used the compliant lubrication to NSF H1 as special contained bush. It also can be used on food machinery. *

Compatibility

Compatible with standard roller chains. (However, there is a difference in their kilowatt ratings.)

Operating temperature range:

-10ºC to 150ºC.

Sprockets

Single strand chains can use RS Sprockets, but double strand chains require special sprockets due to the size difference of their horizontal pitch (C dimension).

RS Double Strand Compatible Lambda Chain

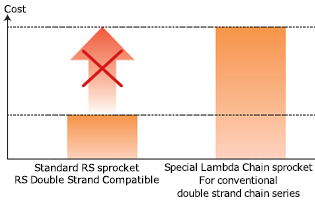

Users of double strand RS Roller Chain can easily make the switch to lube-free operation with RS Double Strand Compatible Lambda Chain.

(1) General use RS sprockets can be used

RS Double Strand Compatible Lambda Chains have the same transverse pitch as RS Roller Chain.

* Can use standard RS sprockets

* Can use standard RS sprockets

* Requires special sprockets for Lambda Chain

Cost Comparison

↓↓↓

Avoid cost increases from changing sprockets

20% higher kW ratings than conventional specifications (multi-strand factor 1.7)

Greater allowable operating range with RS Double Strand Compatible.

List of multi-strand factors

| Chain | Multi-strand factor | kW ratings (index*) |

|---|---|---|

| Double Strand RS Roller Chain | 1.7 | 161 |

| RS Double Strand Compatible Lambda Chain | 1.7 | 121 |

| Conventional double strand Lambda Chain | 1.4 | 100 |

* With conventional double strand Lambda chain as our benchmark of 100

kW ratings

Multi-strand factor

A coefficient used to calculate kW ratings for double strand chain. You can calculate kW ratings by multiplying this factor by the values.

Reference Number System

| RS | 80 | – | LMD | – | 1 |

| (1) | (2) | (3) |

(1) Applicable size: 40, 50, 60, 80, 100, 120, 140, 160*Single strand and RS Double Strand Compatible only

(2) LMD-S when RS Double Strand Compatible

(3) No. of strands

| Model numbers for ordering connecting links (JL) | RS80-LMD-1-JL |

|---|---|

| Model numbers for ordering offset links (OL) | RS80-LMD-1-OL |

Dimensions/Specifications

| Chain Model No. | ||

|---|---|---|

| Single Strand | Double Strand Compatible | Double Strand (conventional) |

| RS40-LMD-1 | RS40-LMD-S-2 | RS40-LMD-2 |

| RS50-LMD-1 | RS50-LMD-S-2 | RS50-LMD-2 |

| RS60-LMD-1 | RS60-LMD-S-2 | RS60-LMD-2 |

| RS80-LMD-1 | RS80-LMD-S-2 | RS80-LMD-2 |

| RS100-LMD-1 | RS100-LMD-S-2 | RS100-LMD-2 |

| RS120-LMD-1 | RS120-LMD-S-2 | |

| RS140-LMD-1 | RS140-LMD-S-2 | |

| RS160-LMD-1 | RS160-LMD-S-2 | |

Safety Precautions for Lambda Chain

- Do not use Lambda Chain if the chain will come in direct contact with food or where coating flakes or wear dust can contaminate food. Also, in non-food applications, appropriately cover the chain or contact a Tsubaki representative about chain selection if using in environments where coating flakes or wear dust present problems. Though nickel is not subject to the japan Food Sanitation Law or the Industry Safety and Health Law, plating on sliding parts can peel.

- Do not use Lambda Chain where there is the possibility of exposure to chemicals, water, or cleaning/degreasing vapors.

- Oil might spatter depending on the usage conditions.

- Please be aware that NSF H1 non-compliant rust prevention oil and assembly oil may be present on the chain.