TSUBAKI Double Pitch Chain Sprockets

Fit Bore Sprocket

Can immediately be used as is with no additional troublesome finishing.

Sprockets can be freely selected from these set finishings.

Available models

| Models | |

|---|---|

| Double Pitch Chain Sprockets | Steel type |

| Stainless steel type | |

| Sprockets for Double Plus Chains | |

We finish standard Easy Finished Bore Type sprockets from in-house stock.

Specifications (set finishings)

You can select the hub type/number of teeth/tooth hardening, shaft bore diameter/tolerance, chamfer, keyway width/tolerance, tap hole finishing (number of taps/position/size), and surface treatment from available models.

Shaft bore finishing range

Bore tolerance

G: G7

H: H7

M: M7

*Grade 7 only

Shaft bore diameter

Set for each size

Specify with three integers

(Plain bore diameter + 1 mm round-up integer-maximum bore diameter)

Chamfer code

N: Tsubaki standard (see table at bottom)

A: C1

B: C2

C: C3

| Shaft bore diameter (mm) | Chamfer amount (mm) |

|---|---|

| 10 to 20 | 1 |

| 21 to 32 | 1.2 |

| 33 to 50 | 1.6 |

| 51 to 80 | 2.5 |

| 81 to 130 | 3 |

*If there is no keyway, use half values of the table above

| Shaft bore diameter | Chamfer code | |||

|---|---|---|---|---|

| 10 to 17 | N | A | – | – |

| 18 to 44 | N | A | B | – |

| 45 to 130 | N | A | B | C |

Keyway

Keyway width tolerances and grades

J: Js9

F: F7

P: P9

E: E9

W: Without keyway

Keyway width

Specify with two integers (JIS standard)

*Without keyway: W00

*Keyway size can only be selected with Js9 and P9 (new JIS). Users can select duplicate min/max keyway sizes for applicable shaft bore diameter ranges

Tapped hole

Number of taps and position

Tap size

Specify with two integers (standard sizes) *Comes with set screws

*Without taps: D0M00. *Select upper and lower standard sizes. It should be greater than M4, and within the keyway width (see the following for more details)

| Applicable Shaft bore diameter mm | Keyway width mm | Standard size | v |

|---|---|---|---|

| 10 to 12 | 4 | M4 | - |

| 12 to 17 | 5 | M5 | M4 |

| 17 to 22 | 6 | M6 | M5 |

| 22 to 30 | 8 | M6 | M5, M8 |

| 30 to 38 | 10 | M8 | M6, M10 |

| 38 to 44 | 12 | M8 | M6, M10 |

| 44 to 50 | 14 | M8 | M6, M10 |

| 50 to 58 | 16 | M10 | M8, M12 |

| 58 to 65 | 18 | M10 | M8, M12 |

| 65 to 75 | 20 | M12 | M10, M16 |

| 75 to 85 | 22 | M12 | M10, M16 |

| 85 to 95 | 25 | M16 | M12, M20 |

| 95 to 110 | 28 | M16 | M12, M20 |

| 110 to 130 | 32 | M20 | M16 |

| Applicable Shaft bore diameter mm | Keyway width mm | Standard size | v |

|---|---|---|---|

| 10 to 13 | 4 | M4 | - |

| 14 to 20 | 5 | M5 | M4 |

| 21 to 30 | 7 | M6 | M5 |

| 31 to 40 | 10 | M8 | M6, M10 |

| 41 to 50 | 12 | M8 | M6, M10 |

| 51 to 60 | 15 | M8※ | M6, M10 |

| 61 to 70 | 18 | M10 | M8, M12 |

| 71 to 80 | 20 | M12 | M10, M16 |

| 81 to 95 | 24 | M12 | M10, M16 |

| 96 to 110 | 28 | M16 | M12, M20 |

| 111 to 125 | 32 | M20 | M16 |

| 126 to 140 | 35 | M20 | M16 |

*Conventionally it is M10 but it will be changed to M8.

Surface treatment

B: Black coating

K: Electroless nickel phosphorous coating

C: Electrogalvanized trivalent chromate treatment

When a black oxide coating is selected, we will also coat finished areas (shaft bore, keyway tolerance, tap hole). Other additional processing will not be performed on finished areas.

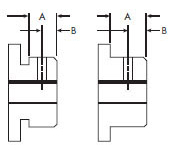

Tapped hole positioning/Set screw specifications

Tapped hole positioning

B = A/2

(May differ depending on welding specifications.)

Long tapped holes will be counterbored.

Set screw specifications

- Steel cup point set screws with hexagonal hole.

- Uses stainless steel screws with stainless steel sprockets.

Reference Number System

| RF2060R-1B1200T | – | H | 030 | N | – | J | 08 | D2 | M06 | – | K |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) |

(1) Base sprocket model number

(2) Bore tolerance

(3) Shaft bore diameter

(4) Shaft bore chamfers

(5) Bore tolerance

(6) Keyway width

(7) Tap size

(8) Tapped hole

(9) Surface treatment