IKEUCHI Industrial Cooling Systems

-

Inlet air cooling system

– Cools air taken in by gas turbines using the evaporate cooling effect of fog to boost electric power generation output during the hot summer months

-

Air fin cooler assist cooling system

– Cooling system that sprays fog on an air-fin cooler to maintain and even increase cooling performance during the hot summer months

-

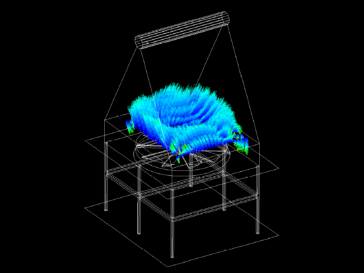

Gas cooling system

– This system cools high-temperature flue gases produced by incinerators, melting furnaces, steelmaking equipment and so forth, bringing it down to 250–300°C (heat-resistance temperature specifications of the bag filters)

-

Kiln cooling system

– This fog cooling system is used to control temperatures for kiln outer shells, for which natural and fan cooling capacities are insufficient and water cooling performance is excessive

-

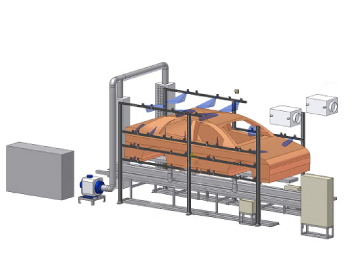

Auto body cooling system

– Sprays fog to cool auto bodies after the oven in coating processes

– Non-drain cooling system

– Switching from fan-type cooling equipment to our system shortens cooling times -

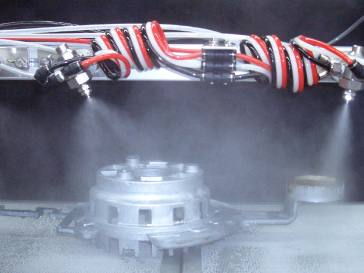

Solid-matter cooling system

– Non-drain cooling system

– Prevents uneven cooling and wetting of objects/surfaces

– Prevents excessively high work environment temperatures

– Shortens cycle times