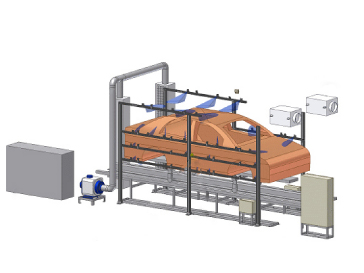

IKEUCHI Auto Body Cooling System

Large-space Cooling and Humidification System

This non-drain rapid cooling system emits fine fog (Dry Fog*1 and Semi-Dry Fog®*2) to rapidly cool auto bodies, chassis and bumpers.

Switching from fan-type cooling equipment to our system can shorten cooling times, improve work-environment problems (by preventing worker burns), and suppress temperature rises in production line facilities to cut cooling costs for the overall factory environment.

The use of sensors, controller devices, water treatment equipment and so forth cools automotive bodies without wetting them.

Features

• Non-drain auto body cooling system that uses Dry Fog (*1) and Semi-Dry Fog® (*2).

• The fog vaporizes immediately when contacting cooling target surfaces, enabling cooling via the latent heat of vaporization phenomenon.

• Solves problems related to insufficient cooling performance, which is often seen with air-cooling approaches.

*1) We define Dry Fog as a very fine fog with a uniform, mean droplet diameter (mean fog droplet size) of 10 μm or less.

Because Dry Fog’s exceedingly fine spray droplets remain intact without bursting when they come into contact with objects such as a walls and people, they do not wet these impact surfaces.

*2) We define Semi-Dry Fog® as a fog with a mean droplet diameter (mean fog droplet size) of 10–30 μm.

This highly useful fog features fine droplets and does not include large droplets which can result in wetting of objects and surfaces.

Applications

Measures against intense heat: prior to masking (sealing), near the outlet of the undercoating drying furnace

Measures against burns during inspections and polishing operations: near the oven outlet (undercoating, intermediate coating and final coating), on the repair line