MJS-CSK-RD

Flexible Coupling – Jaw-type (Short) – Clamping + Key Type

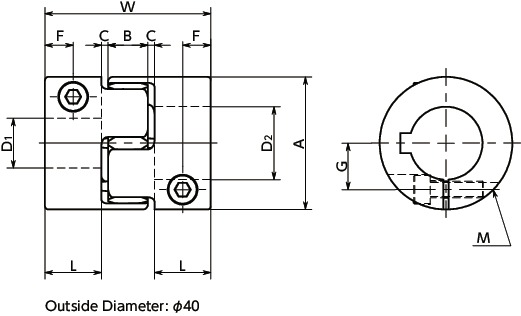

Dimension Drawing

Dimensions/Specifications/CAD

| Part Number | A | L | W | B | C | F | G | M | Wrench Torque (N・m) |

|---|---|---|---|---|---|---|---|---|---|

| MJS-40CSK-RD | 40 | 17 | 50 | 12 | 2 | 8.5 | 14 15.75 | M5 M4 | 8 3.5 |

| MJS-55CSK-RD | 55 | 18 | 54 | 14 | 2 | 9 | 20 21 | M6 M5 | 13 8 |

| MJS-65CSK-RD | 65 | 21 | 62 | 15 | 2.5 | 10.5 | 24 25 | M8 M6 | 28 13 |

| Part Number | Max. Bore Diameter (mm) | Rated Torque* (N・m) | Max. Torque* (N・m) | Backlash Zero Allowable Transmission Torque(N・m)*** | Max. Rotational (min-1) | Static Torsional Stiffness (N・m/rad) | Max. Lateral Misalignment (mm) | Max. Angular Misalignment (°) | Max. Axial Misalignment (mm) | Sleeve Hardness | Mass** (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MJS-40CSK-RD | 25 | 17 | 34 | 1.2 | 15000 | 1200 | 0.1 | 1 | 0~+1.2 | A98 | 96 |

| MJS-55CSK-RD | 32 | 60 | 120 | – | 11000 | 2600 | 0.1 | 1 | 0~+1.4 | A98 | 210 |

| MJS-65CSK-RD | 38 | 160 | 320 | – | 9000 | 4900 | 0.1 | 1 | 0~+1.5 | A98 | 330 |

* Correction of rated torque and max. torque due to load fluctuation is not required.However, if ambient temperature exceeds 30°C, be sure to correct the rated torque and max. torque with temperature correction factor shown in the table.MJC’s allowable operating temperature is -20°C to 60°C.

** These are values with max. bore diameter.

*** For transmission of backlash0Zero, please use a tight fit sleeve.

| Part Number | Stock Bores D1-D2 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | |

| MJS-40CSK-RD | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – | – | – | – | – |

| MJS-55CSK-RD | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – | – |

| MJS-65CSK-RD | – | – | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

All products are provided with hex socket head cap screw.

Recommended dimensional allowances of applicable shaft diameter are h6 and h7.

A set of hubs with clamping type for one side and clamping + key type for the other side is available upon request.

In case of mounting on D-cut shaft, be careful about the position of the D-cut surface of the shaft.

Material/Finish

| MJS-CS/MJS-CSK | |

|---|---|

| Hub | A2017 Alumite Treatment |

| Sleeve | Polyurethane |

| Hex Socket Head Cap Screw | SCM435 Ferrosoferric Oxide Film (Black) |

Structure

Clamping Type MJS-CS-BL,MJS-CS-EBL,MJS-CS-EGR,MJS-CS-ERD,MJS-CS-EWH,MJS-CS-GR,MJS-CS-RD,MJS-CS-WH

MJS-**CS-**Tight Fit

MJS-**CS-E**Easy Fit

Clamping + Key Type MJS-CSK-BL,MJS-CSK-EBL,MJS-CSK-EGR,MJS-CSK-ERD,MJS-CSK-EWH,MJS-CSK-GR,MJS-CSK-RD,MJS-CSK-WH

MJS-**CSK-**Tight Fit

MJS-**CSK-E**Easy Fit

Sleeve

Characteristics

- Applicable motors

Tight Fit Easy Fit Servomotor ◎ ○ Stepping Motor ◎ ◎ General-Purpose Motor ◎ ◎ ◎: Excellent ○: Very good

- Property

Tight Fit Easy Fit Zero Backlash ○ – High Torque ◎ ◎ Allowable Misalignment ○ ○ Vibration Absorption ◎ ◎ Electrical Insulation ◎ ◎ Assembling ○ ◎ Allowable Operating Temperature -20℃ to 60℃ -20℃ to 60℃ ◎: Excellent ○: Very good

- This is a jaw type flexible coupling.

- It is a short type and more compact than MJC.

- Tight Fit enables transmission with zero backlash at low torque.

- Easy fit allows assembling and separation of hubs.

- Excellent flexibility allows eccentricity, angular misalignment and twisting vibration to be accepted.

- It has electrical insulation. Resistance value: Not less than 2 MΩ

- Sleeve Type

Selection

The area bounded by the shaft diameter and rated torque indicates is the selection size.

Selection example

In case of selected parameters of shaft diameter of φ15 and load torque of 6 N•m, the selected size for MJS-**CS-RD, MJS-**CS-ERD is MJS-40CS-RD, MJS-40CS-ERD.

Ambient Temperature / Temperature Correction Factor

| Ambient Temperature | Temperature Correction Factor |

|---|---|

| -20℃ to 30℃ | 1.00 |

| 30℃ to 40℃ | 0.80 |

| 40℃ to 60℃ | 0.70 |

Details of Shaft Hole

| Standard Bore Diameter D | Keyway | Key | ||||||

|---|---|---|---|---|---|---|---|---|

| b | t | Nominal Dimension b x h | ||||||

| Standard Dimension | Allowance (JS9) | Standard Dimension | Allowance | |||||

| 10・11・12 | 4 | ±0.0150 | 1.8 | 0 to +0.1 | 4×4 | |||

| 14・15・16 | 5 | ±0.0150 | 2.3 | 0 to +0.1 | 5×5 | |||

| 18・19・20・22 | 6 | ±0.0150 | 2.8 | 0 to +0.1 | 6×6 | |||

| 24・25・28・30 | 8 | ±0.0180 | 3.3 | 0 to +0.2 | 8×7 | |||

| 32・35・38 | 10 | ±0.0180 | 3.3 | 0 to +0.2 | 10×8 | |||

Sleeve Details

Tight Fit

The hub and sleeve are press-fit and can be used under zero backlash*.Since the sleeve’s vibration absorption can raise the gain of a servomotor, this unit can achieve high responsive operation exceeding the Disk coupling.

*For the torque used under zero backlash, please refer to Performance table.

Easy Fit

This unit allows you to easily assemble and partition the hub and sleeve.

This allows you to reduce the time of assembling the unit and maintenance.

It is possible to mount a hub on the shaft in advance and easily assemble the unit even in a location where the coupling is less-visible.

Slip Torque

Concerning the sizes shown in the table, please note that the shaft’s slip torque is smaller than the max. torque of MJS-CS.

| Part Number | Bore Diameter (mm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | |

| MJS-40CS | 28.9 | 35.6 | 37.7 | ||||||||||||||||

| MJS-55CS | 40.2 | 46.7 | 53.2 | 66.1 | 72.6 | 79 | 92 | 98.4 | 104 | 117 | 130 | 137 | 145 | ||||||

| MJS-65CS | 113 | 123 | 134 | 155 | 165 | 176 | 197 | 218 | 228 | 260 | 281 | 302 | 300 | 300 | |||||

These are test values based on the condition of shaft’s dimensional allowance: h7, hardness: from 34-40 HRC, and screw tightening torque of the values described in MJS-CS dimensional table.

Change in static torsional stiffness due to temperature

This is a value under the condition where the static torsional stiffness at 20°C is 100%.

The change of torsional stiffness within the range of allowable operating temperature is as shown in the graph.

Before using the unit, be aware of the deterioration of responsiveness.

Eccentric Reaction Force